Understanding Non Grain Oriented Electrical Steel

In the intricate tapestry of the electrical industry, a crucial thread weaves seamlessly through the design and performance of countless devices: Non Grain Oriented Electrical Steel (NGOES). At the forefront of technological innovation, Non Grain Oriented Electrical Steel plays a pivotal role in enhancing the efficiency and reliability of electrical components. Let’s delve into the essence of Non Grain Oriented Electrical Steel, unraveling its significance and the distinctive properties that set it apart.

Defining Non Grain Oriented Electrical Steel

Non Grain Oriented Electrical Steel, often abbreviated as Non Grain Oriented Electrical Steel, is a specialized type of electrical steel meticulously crafted to cater to the dynamic needs of the electrical industry. Unlike its grain-oriented counterpart, which exhibits directional magnetic properties, Non Grain Oriented Electrical Steel boasts an isotropic nature, making it a versatile choice for a myriad of applications.

The significance of Non Grain Oriented Electrical Steel lies in its ability to mitigate energy losses, a critical concern in the design and functionality of electrical devices. As a cornerstone material, it empowers the efficient transformation of electrical energy, ensuring that the intricate machinery of transformers, motors, and generators operates with precision and reliability.

Key Properties Setting Non Grain Oriented Electrical Steel Apart

1. High Magnetic Permeability:

Non Grain Oriented Electrical Steel distinguishes itself through its exceptional magnetic permeability, allowing for optimal magnetic flux distribution. This property is paramount in applications where magnetic induction and energy efficiency are non-negotiable.

2. Low Core Loss:

One of the defining characteristics of Non Grain Oriented Electrical Steel is its remarkably low core loss. This means that the material minimizes energy dissipation in the form of heat during the magnetic flux cycles, resulting in heightened efficiency and reduced operational costs.

3. Isotropic Nature:

The isotropic nature of Non Grain Oriented Electrical Steel ensures uniform magnetic properties in all directions, providing design flexibility and reliability in various orientations. This characteristic is particularly advantageous in the manufacturing of intricate components where magnetic flux may vary.

4. Versatility in Applications:

Non Grain Oriented Electrical Steel finds itself at home in an array of applications spanning from power generation to distribution. Its adaptability makes it a preferred choice in the production of transformers, motors, and other electrical devices where efficiency and reliability are paramount.

5. Precision in Manufacturing:

Electrical Steel supplier, such as HXSCO, understand the importance of precision in Non Grain Oriented Electrical Steel manufacturing. The material is processed with meticulous attention to detail, ensuring that the final product adheres to strict industry standards and customer specifications.

6. Surface Insulation:

To enhance its performance further, Non Grain Oriented Electrical Steel often comes coated with a surface insulation layer. This not only prevents core loss but also adds an extra layer of durability and longevity to the material, making it a sustainable choice for long-term applications.

In the competitive landscape of the electrical industry, the choice of Non Grain Oriented Electrical Steel becomes a strategic decision. As an Electrical Steel supplier, HXSCO takes pride in offering a range of Non Grain Oriented Electrical Steel products that embody these key properties, providing our global clientele with a reliable and efficient solution for their electrical steel needs.

Whether you are designing the heart of a power distribution system or crafting the precision components of an electric motor, the unique properties of Non Grain Oriented Electrical Steel ensure that your creations stand at the pinnacle of efficiency and performance. With HXSCO as your trusted Electrical Steel supplier, you gain access not just to a product, but to a partnership that values quality, innovation, and your success in the ever-evolving electrical landscape. Non Grain Oriented Electrical Steel isn’t just a material; it’s the conduit through which your electrical visions transform into reality.

Technical Insights Into Non Grain Oriented Electrical Steel Production

In the intricate tapestry of the electrical industry, a crucial thread weaves seamlessly through the design and performance of countless devices: Non Grain Oriented Electrical Steel (NGOES). At the forefront of technological innovation, Non Grain Oriented Electrical Steel plays a pivotal role in enhancing the efficiency and reliability of electrical components. Let’s delve into the essence of Non Grain Oriented Electrical Steel, unraveling its significance and the distinctive properties that set it apart.

Raw Material Selection

The journey of crafting exceptional Non Grain Oriented Electrical Steel begins with the selection of raw materials. At electrical steel supplier HXSCO, we source the finest steel alloys, meticulously chosen for their purity and magnetic properties. The composition of these alloys forms the foundation for Non Grain Oriented Electrical Steel, laying the groundwork for the material’s high magnetic permeability and low core loss—crucial characteristics that define its superiority in the electrical industry.

Melting and Casting

The production process kicks into gear with the melting and casting of the selected alloys. Our state-of-the-art facilities employ advanced induction furnaces to achieve precise temperature control, ensuring the homogeneity of the molten metal. This step is fundamental in preventing grain orientation, a key factor that distinguishes Non Grain Oriented Electrical Steel from its grain-oriented counterpart. The molten metal is then cast into slabs, setting the stage for subsequent processing.

Hot Rolling

Hot rolling follows casting, where the slabs undergo a series of carefully controlled reductions in thickness. This process not only refines the material’s thickness to meet specific customer requirements but also imparts the necessary mechanical properties that define Non Grain Oriented Electrical Steel. HXSCO’s commitment to precision is evident in our rigorous control of rolling parameters, guaranteeing uniformity and consistency across the entire material surface.

Cold Rolling and Annealing

Cold rolling is a critical phase where the material undergoes further reduction in thickness, resulting in sheets or coils with the desired dimensions. To maintain the isotropic nature of Non Grain Oriented Electrical Steel, cold rolling is accompanied by periodic annealing. This thermal treatment serves to relieve stresses, refine grain structure, and enhance magnetic properties. HXSCO’s annealing processes are finely tuned to achieve the delicate balance required for optimal performance in electrical applications.

Surface Insulation Coating

To enhance Non Grain Oriented Electrical Steel’s performance and longevity, electrical steel supplier HXSCO introduces a surface insulation coating. This coating not only provides an additional layer of protection against core loss but also contributes to the material’s resistance to environmental factors. The application of the coating is a precision-driven process, ensuring uniform coverage and adherence.

Precision Slitting and Cutting

As the Non Grain Oriented Electrical Steel material takes its final form—whether in sheets, coils, or strips—precision becomes the focal point of the manufacturing process. Electrical steel supplier HXSCO employs advanced slitting and cutting technologies to tailor the material to exact customer specifications. This step is instrumental in ensuring that the Non Grain Oriented Electrical Steel components seamlessly integrate into diverse electrical applications with utmost precision.

Quality Control Measures

Throughout every stage of production, HXSCO implements stringent quality control measures. From chemical analysis and mechanical property testing to dimensional inspections, our commitment to delivering Non Grain Oriented Electrical Steel of uncompromising quality is unwavering. We understand that in the world of electrical engineering, precision and reliability are non-negotiable, and our quality control processes reflect this understanding.

Customization for Client Requirements

Recognizing the diverse needs of our global clientele, HXSCO offers customization options to tailor Non Grain Oriented Electrical Steel products according to specific client requirements. Whether it’s a unique thickness, width, or surface finish, our technical team collaborates closely with clients to ensure that the final product aligns seamlessly with their application needs.

At electrical steel supplier HXSCO, our role as an Electrical Steel supplier goes beyond delivering a product; it extends to providing a solution crafted with technical precision and unwavering dedication to quality. As the keyword “Non Grain Oriented Electrical Steel” resonates through every stage of our production process, it symbolizes not just a material, but a testament to excellence in the field of electrical engineering. Trust HXSCO to illuminate the path to precision and reliability in every electrical application.

Applications Of Non Grain Oriented Electrical Steel

In the dynamic tapestry of industries reliant on seamless energy transformation, Non Grain Oriented Electrical Steel (NGOES) emerges as the linchpin, embodying efficiency and precision in every application it graces. As an esteemed Electrical Steel supplier, HXSCO takes pride in illuminating the diverse landscape of Non Grain Oriented Electrical Steel applications, where its unique properties shine.

Transformers

Transformers stand as the vanguards of power distribution systems, orchestrating the seamless transfer of electrical energy. Non Grain Oriented Electrical Steel takes center stage in transformer cores, ensuring optimal magnetic flux distribution. The result is a transformative synergy of efficiency and reliability, with Non Grain Oriented Electrical Steel playing a pivotal role in minimizing energy losses and maximizing the overall performance of transformers.

Electric Motors

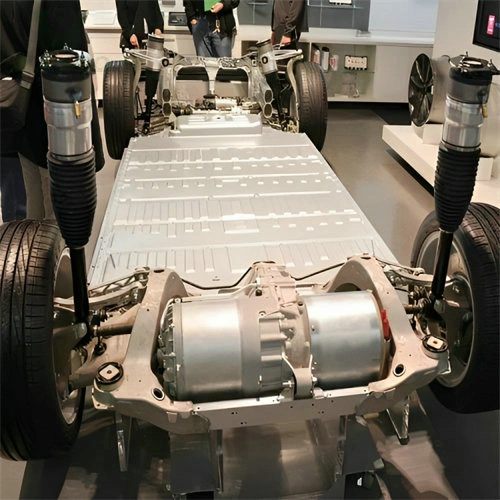

In the heart of electric motors, Non Grain Oriented Electrical Steel finds a realm where its isotropic nature and low core loss prove indispensable. Motors crafted with Non Grain Oriented Electrical Steel components exhibit enhanced efficiency, reduced heat dissipation, and prolonged operational life. These advantages are especially crucial in applications where motors operate continuously, such as industrial machinery and electric vehicles.

Generators

The heartbeat of power generation, generators demand materials that can endure rigorous operational cycles. Non Grain Oriented Electrical Steel rises to the occasion, contributing to the efficiency and performance of generator cores. The low core loss property ensures that the energy conversion process remains optimized, translating into reliable power generation across a spectrum of industries.

Appliances and Consumer Electronics

From the hum of refrigerators to the whisper of air conditioners, Non Grain Oriented Electrical Steel plays a silent yet crucial role in the efficiency of household appliances. Its presence ensures that these devices operate with precision, minimizing energy wastage and contributing to the overall sustainability of modern living.

Renewable Energy Applications

In the realm of renewable energy, Non Grain Oriented Electrical Steel is a key player in the design of components for wind turbines and solar inverters. The material’s ability to maintain efficiency in varying orientations makes it an ideal choice for harnessing energy from unpredictable sources, contributing to the advancement of sustainable energy solutions.

Magnetic Shields and Inductors

Non Grain Oriented Electrical Steel’s high magnetic permeability renders it invaluable in the manufacturing of magnetic shields and inductors. These components are vital in applications where electromagnetic interference must be minimized or controlled, such as in sensitive electronic equipment and communication devices.

Real-world Examples and Success Stories

Example 1: Transformative Efficiency in Power Grids

In a major urban center, a power distribution company faced challenges with energy losses in its grid transformers. By incorporating NGOES supplied by HXSCO, the company witnessed a substantial reduction in core losses. This not only elevated the efficiency of the transformers but also led to significant cost savings over time, validating NGOES as a strategic choice for large-scale energy distribution.

Example 2: Driving Innovation in Electric Vehicles (EVs)

A leading automotive manufacturer sought to enhance the efficiency of its electric vehicle motors. Collaborating with HXSCO, they integrated NGOES components into the motor cores. The result was a notable increase in motor efficiency, extending the driving range of their electric vehicles. This success story exemplifies NGOES’s role in shaping the future of sustainable transportation.

Example 3: Empowering Renewable Energy Initiatives

In a wind farm project, NGOES proved instrumental in the design of generator cores for wind turbines. The material’s ability to withstand varying wind directions and deliver consistent efficiency contributed to increased energy output. This success story underscores NGOES’s vital role in advancing renewable energy technologies.

HXSCO: Pioneering Excellence In Non Grain Oriented Electrical Steel

In the ever-evolving landscape of the electrical steel industry, HXSCO stands as a beacon of expertise, spearheading advancements in Non Grain Oriented Electrical Steel (NGOES). As a dedicated Electrical Steel supplier, our commitment to quality, innovation, and unwavering customer satisfaction forms the bedrock of our success.

Specialization in Non Grain Oriented Electrical Steel

HXSCO’s journey into the realm of Non Grain Oriented Electrical Steel is marked by a relentless pursuit of excellence. Our specialization in crafting superior Non Grain Oriented Electrical Steel products is rooted in a fusion of cutting-edge technology, precision manufacturing processes, and a team of experts committed to pushing the boundaries of what is achievable.

Precision in Manufacturing:

At the core of our specialization lies a meticulous manufacturing process that ensures every coil, sheet, or strip of Non Grain Oriented Electrical Steel meets the highest standards of quality. From the selection of raw materials to the final stages of customization, precision is our guiding principle. HXSCO’s state-of-the-art facilities are equipped with advanced technologies, enabling us to deliver Non Grain Oriented Electrical Steel products with uniform properties, consistency, and reliability.

Adherence to International Standards:

As a responsible Electrical Steel supplier, we recognize the global impact of our products. HXSCO adheres rigorously to international standards in the production of Non Grain Oriented Electrical Steel, ensuring that our materials not only meet but exceed industry benchmarks. This commitment to quality has positioned HXSCO as a trusted partner for clients seeking excellence in their electrical applications.

Commitment to Quality

Stringent Quality Control Measures:

Quality is not just a goal at HXSCO; it is ingrained in our processes. Stringent quality control measures are implemented at every stage of production, from the initial melting and casting of alloys to the final inspection of finished Non Grain Oriented Electrical Steel products. This unwavering commitment to quality guarantees that our customers receive electrical steel that not only meets their specifications but surpasses their expectations.

Continuous Improvement:

In a landscape defined by innovation, HXSCO is committed to continuous improvement. Our research and development initiatives are dedicated to exploring new technologies, refining manufacturing processes, and staying at the forefront of advancements in Non Grain Oriented Electrical Steel production. This commitment ensures that our clients benefit from materials that embody the latest in electrical steel technology.

Innovation in Electrical Steel

Customization for Diverse Applications:

Recognizing the diverse needs of our global clientele, HXSCO embraces innovation through customization. Our technical team collaborates closely with clients to understand their unique requirements and tailors Non Grain Oriented Electrical Steel products accordingly. This bespoke approach ensures that our Non Grain Oriented Electrical Steel seamlessly integrates into a myriad of applications, from transformers to electric vehicles.

Sustainability Initiatives:

In an era where sustainability is a key consideration, HXSCO integrates eco-friendly practices into our production processes. Our NGOES products often come with surface insulation coatings that not only enhance performance but also contribute to the longevity and sustainability of the material. This commitment to environmental responsibility reflects our dedication to creating a positive impact on the industries we serve.

Customer Satisfaction

Collaborative Partnerships:

HXSCO views customer relationships as collaborative partnerships. We engage with our clients from the initial consultation to the final delivery, ensuring open communication and a deep understanding of their unique needs. This collaborative approach allows us to not only meet but exceed customer expectations, fostering long-term relationships built on trust and mutual success.

Responsive Customer Support:

Our commitment to customer satisfaction extends beyond the product itself. HXSCO’s customer support is responsive and dedicated to addressing inquiries, providing technical assistance, and ensuring a seamless experience throughout the procurement process. We recognize that our clients’ success is intertwined with ours, and we strive to be a reliable partner in their journey.

In the realm of Non Grain Oriented Electrical Steel, HXSCO stands as more than an Electrical Steel supplier; we are architects of efficiency, innovators in technology, and partners in our clients’ success. The keyword “Non Grain Oriented Electrical Steel” echoes through every aspect of our operations, symbolizing a commitment to excellence that defines HXSCO in the global electrical steel landscape. Trust us to illuminate the path to superior NGOES solutions and a future powered by precision and innovation.

Conclusion

As we draw the curtain on this exploration of Non Grain Oriented Electrical Steel (NGOES) and its transformative applications, it becomes evident that precision and excellence are not just aspirations but the cornerstone of progress in the electrical industry. At HXSCO, we take immense pride in being more than just an Electrical Steel supplier; we are architects of efficiency, pioneers in innovation, and steadfast partners in your journey towards unparalleled electrical performance.

The keyword “Non Grain Oriented Electrical Steel” resonates throughout our commitment to crafting materials that transcend industry standards. Our specialization in NGOES is a testament to a journey marked by precision manufacturing, stringent quality control, and a relentless pursuit of innovation. With every coil, sheet, or strip of NGOES that leaves our facilities, we contribute to the seamless energy transformation that powers industries around the globe.

As an Electrical Steel supplier, we understand the dynamic landscape of the electrical industry and the pivotal role NGOES plays in shaping its future. Our commitment to quality, evident in our adherence to international standards and continuous improvement initiatives, ensures that our clients receive not just a material but a solution that stands at the forefront of electrical steel technology.

In the ever-evolving tapestry of electrical applications, HXSCO’s NGOES emerges as the conduit through which efficiency, sustainability, and reliability converge. We invite you to embark on a journey of innovation and partnership with HXSCO, where the keyword “Non Grain Oriented Electrical Steel” is more than a term; it’s a promise of excellence that powers the foundations of modern electrical engineering.

As you navigate the intricate requirements of your electrical projects, trust HXSCO to be your unwavering partner, providing NGOES solutions that illuminate the path to superior performance. Let’s together shape a future where electrical efficiency is not just a standard but a benchmark exceeded. Contact us today and experience the HXSCO difference—an alliance built on precision, innovation, and the commitment to be your trusted Electrical Steel supplier of choice.