China Aluminum Coil Supplier – Wholesale Aluminum Coil

Aluminum coils are a widely used metal product. They are flat-rolled sheets of aluminum. Continuous coils that are easy to transport, store, and process. The composition of aluminum coils mainly consists of pure aluminum or various aluminum alloys. Each alloy has unique properties to suit different applications.

We are a leading aluminum coil supplier in China, producing a diverse range of aluminum coils, including the 1000, 3000, 5000, and 8000 Series. Our aluminum coils are known for their excellent malleability and conductivity, making them ideal for cookware, lighting, automotive parts, and building decoration applications. We offer coils up to a maximum width of 2600mm to meet both standard and customized needs. We can provide standard aluminum coils and custom aluminum coil manufacturing.

Specifications of Aluminum Coil

| Attribute | Description |

|---|---|

| Thickness | 0.2 mm – 8 mm |

| Width | Aluminum coil are available in various widths, ranging from a few inches to several feet. |

| Surface Finish | Aluminum coils can have different surface finishes, such as mill finish (uncoated), embossed, brushed, or coated with various finishes for enhanced aesthetics and protection. |

| Core Diameter | The inner core diameter of aluminum coil is typically standardized, with common sizes being 508 mm (20 inches) or 610 mm (24 inches). |

| Temper |

The temper designation indicates the state of the aluminum coil concerning its hardness and malleability. H14: Strain-hardened (half-hard) H24: Strain-hardened and then annealed (half-hard) H32: Strain-hardened and stabilized (quarter-hard) H34: Strain-hardened and stabilized (quarter-hard) H36: Strain-hardened and stabilized (quarter-hard) O: Annealed (soft) |

| Origin | China |

| Shipping | 3-15 Days |

| Price | Depending on the order |

Aluminum Alloy Grade of Aluminum Coil

| Series | Alloys | Description | Applications |

|---|---|---|---|

| 1000 Series | 1050, 1060, 1070, 1100 | Industrial Pure Aluminum: The 1000 series alloy is almost pure aluminum. Usually it has an aluminum content of at least 99%. These coils have excellent corrosion resistance and high electrical conductivity. | Chemical equipment, food industry equipment, and other applications requiring high corrosion resistance. |

| 2000 Series | 2024 (2A12), LY12, LY11, 2A11, 2A14 (LD10), 2017, 2A17 | Aluminum-Copper Alloys: Known for higher hardness, with copper content being the highest, approximately 3-5%. | Aerospace industry, where high strength and fatigue resistance are required. |

| 3000 Series | 3A21, 3003, 3103, 3004, 3005, 3105 | Aluminum-Manganese Alloys: The main alloying element of the 3000 series alloy is manganese. These coils have moderate strength. They have better formability than the 1000 series. | Building materials, mechanical parts, storage equipment, and other applications requiring high strength and high corrosion resistance. |

| 4000 Series | 4A03, 4A11, 4A13, 4A17, 4004, 4032, 4043, 4043A, 4047, 4047A | Aluminum-Silicon Alloys: Typically contains 4.5-6.0% silicon, used for building materials, mechanical parts, forging materials, welding materials, with low melting point and good corrosion resistance. | Applications requiring high wear resistance and low thermal expansion, such as engine parts and wear-resistant surfaces. |

| 5000 Series | 5052, 5083, 5754, 5005, 5086, 5182 | Aluminum-Magnesium Alloys: The main alloying element of the 5000 series alloy is magnesium. These coils have strong corrosion resistance and good weldability. | Shipbuilding, automotive, aircraft welding parts, subway, and light rail. |

| 6000 Series | 6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 | Aluminum-Magnesium-Silicon Alloys: The 6000 series alloy has magnesium and silicon as alloying elements. These coils have excellent extrudability. | Applications requiring high corrosion resistance and oxidation resistance, such as construction profiles and aerospace parts. |

| 7000 Series | 7075, 704, 7A09, 7A52, 7A05 | Aluminum-Zinc-Copper Alloys: The main alloying element of the 7000 series alloy is zinc. This type of coil has a high strength-to-weight ratio. | Aerospace industry and applications requiring high strength and hardness. |

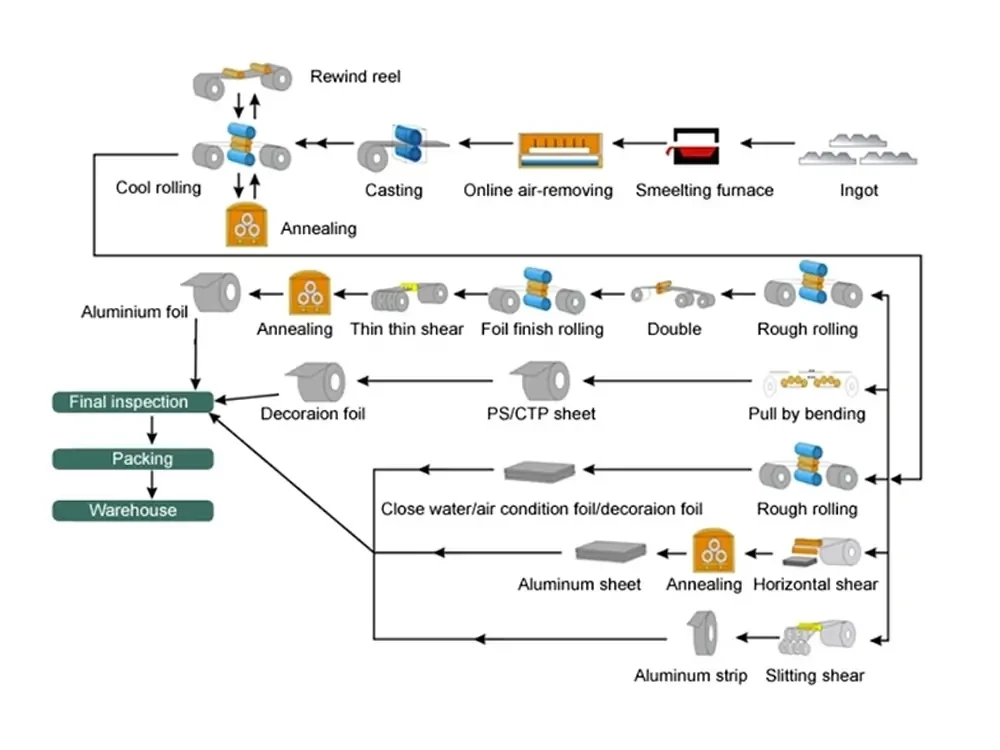

Manufacturing Process of aluminum coils: From Raw Material To Coil Form

HXSCO is an aluminum coil supplier that offers a one-stop shopping experience. We do all our own processing (from raw material extraction to the final coil) in-house at our factory. Our specialty is manufacturing high-quality aluminum coils with consistent standards.

Raw Material Procurement:

- Firstly, we buy high-quality ingots of aluminum or scrap aluminum that has been recycled. These materials are carefully chosen by responsible aluminium coil manufacturers to ensure uniformity and purity of raw materials.

Smelting and Casting:

- The selected aluminum is then melted in the furnace. The molten aluminum is then cast into semi-finished products such as billets or slabs.

Hot Rolling:

- We reduce the thickness of the billet or slab through hot rolling to achieve the desired specifications. This process improves the mechanical properties of aluminum and makes it more ductile.

Cold Rolling:

- After hot rolling, the sheet metal undergoes cold rolling which further reduces its thickness to meet specific coil application requirements. Cold rolling ensures a smoother surface finish as well as tighter tolerances on thickness.

Annealing:

- To optimize its properties, cold rolled coils are annealed. As such, this heat treatment process relieves stresses within and increases the material’s flexibility.

Coiling:

- After annealing, the aluminum strip is coiled into large continuous rolls known as the aluminum coil. These coils are ready for further processing or direct use in various industries.

The Advantages Of Aluminum Coil

As a trusted aluminum coil manufacturer, HXSCO proudly provides premium aluminum coils that take advantage of these exceptional properties. With a commitment to quality, durability, and environmental responsibility, HXSCO delivers high-performance aluminum coils. We also have a large stock of aluminum coils at our factory to meet the diverse needs of our customers around the globe.

Excellent corrosion resistance

Aluminum coils have excellent corrosion resistance. They are very durable in harsh environments. The natural oxide layer sets them apart from some metals that require coatings or surface treatments to achieve corrosion resistance.

Lightweight and strong

Aluminum is a low-density metal. It is much lighter than other common metals, such as steel, but has a high strength-to-weight ratio. Therefore, aluminum coils can withstand huge loads while ensuring a low total weight.

Excellent thermal conductivity

Aluminum coils have excellent thermal conductivity. It promotes efficient heat transfer and heat dissipation. This property ensures effective cooling and temperature regulation. It extends the life of the equipment and improves overall system performance.

Environmental protection and recyclability

Aluminum is 100% recyclable without any loss in quality and is one of the most recycled materials in the world. Due to their recyclability and energy-saving properties, aluminum coils are the first choice for environmental protection.

Diverse Applications Of Aluminum Coil

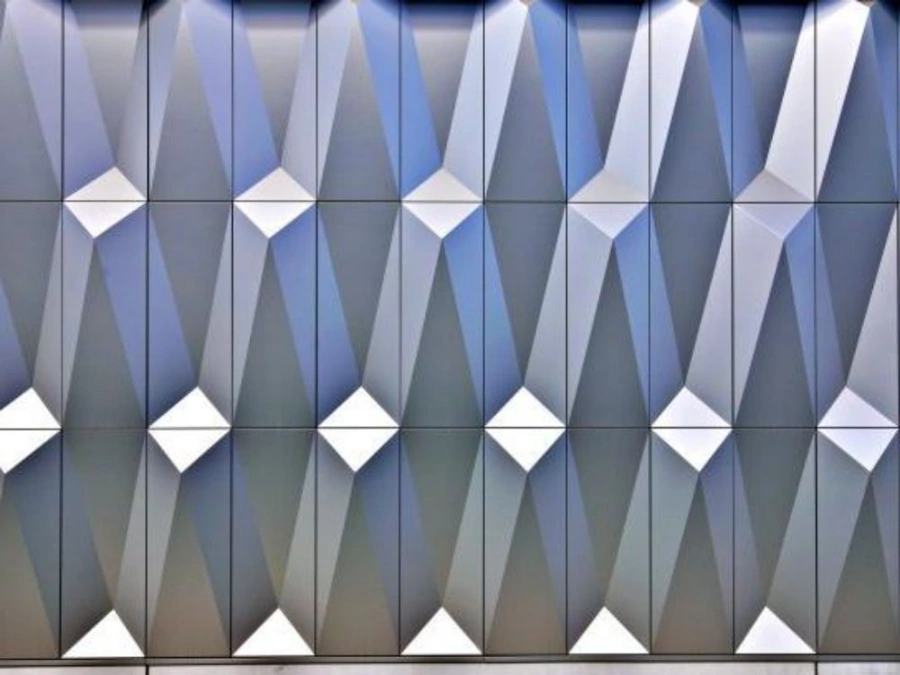

Building and Construction

Roofing and Siding: Aluminum coils are suitable for making durable, weather-resistant roofing and siding. These structures are often coated or painted for extra protection and aesthetics.

Window Frames and Curtain Walls: Aluminum coils are strong and lightweight. Therefore, modern buildings often use them as window and curtain wall frames.

Automotive Industry

Body Panels and Trim: Aluminum’s light weight reduces vehicle weight and improves fuel efficiency. Aluminum coils are used to make body panels, trim, and decorative parts.

Heat Exchangers: Aluminum has excellent thermal conductivity, making it ideal for use in radiators and air conditioning units within vehicles.

.

Electrical Applications

Transformers: Aluminum coils are often used in power transformers. They are effective conductors and cost less than copper.

..

Cables and Wiring: Aluminum coils are used for overhead wires in electrical grids due to their electrical conductivity and lightweight properties.

Consumer Goods

Home Appliances: Aluminum coils are used in various home appliances, including refrigerators, air conditioners, and microwave ovens. They are used for both structural and thermal purposes.

Cookware: Aluminum has excellent thermal conductivity. This feature makes it ideal for cookware such as pots, pans, and baking sheets.

Packaging Industry

Cans and Containers: Aluminum coils can be processed into sheets for beverage cans, food containers, and foil packaging.

Signs and Advertising

Commercial Signs: Aluminum is ductile. This feature makes shaping and processing into signs for indoor and outdoor advertising applications easy.

How to choose aluminum coil?

To ensure the material meets your needs, you must choose the right aluminum coil. There are several factors to consider when choosing the right aluminum coil, and here are some simple steps.

- Determine thickness and width (which affects durability and usability).

- Evaluate alloy type. Different series of aluminum alloys have different properties. For example, the 1000 series is highly ductile; the 5000 series has high strength and corrosion resistance.

- Consider the appropriate temper grade to meet specific mechanical requirements. The temper of an aluminum coil affects its hardness and strength.

- Check the specific surface finish you need to provide additional corrosion protection and aesthetic value. For example, rolled finish, painted, or anodized.

- Determine the end use. For applications exposed to harsh conditions, you need to choose an alloy with corrosion resistance.

- Certification and standards compliance. Choose a Chinese aluminum coil supplier like HXSCO that adheres to international quality standards and provides certified materials. You will receive high-quality aluminum coils that meet strict industry standards.

- Supplier reputation. Choose a reputable company with a track record of reliability and quality. HXSCO Aluminum Coil Manufacturers consistently delivers high-quality aluminum coil fabrication services.

Considering these factors, you can make an informed decision when choosing wholesale aluminum coils, ensuring compatibility with your project’s specific requirements. At HXSCO, we provide high-quality custom aluminum coil materials that meet industry standards and customer specifications.

What can HXSCO aluminum coil suppliers offer you?

As a leading aluminum coil supplier in China, HXSCO has strong supply capabilities and comprehensive services. Here are the services we can provide:

1. High Production Capacity

HXSCO’s own factory has strong production and supply capabilities. We can supply up to 50,000 tons of aluminum coils per month. This ensures that we can handle large-volume orders and maintain a stable supply chain for major projects.

2. Quality and Compliance

All aluminum coils are made according to strict international quality standards. Our products have the necessary certifications for various industrial applications.

3. Advanced Packaging Solutions

We use high-quality, durable packaging materials to transport our products. Our packaging protects aluminum coils from moisture and dirt during transportation and storage.

4. Experienced Service

With many years of experience in the aluminum industry, HXSCO has a unique understanding of market trends and customer needs. Our experienced team can provide tailor-made aluminum product solutions.

5. Value-added Processing

We provide custom manufacturing services, including cutting, slitting, and surface treatment. Customers can receive materials that can be used immediately for their specific manufacturing processes.

6. Wide Range of Applications

Our aluminum coils suit various applications, including construction, automotive, aerospace, and electronics.

Choosing HXSCO as your aluminum coil supplier will give you access to large-scale production capabilities, extensive experience, and a commitment to quality and satisfaction. We are committed to providing high-quality aluminum coil solutions that meet the specific needs of different industries.