What Is Colored Stainless Steel?

Colored Stainless Steel is an innovative and aesthetically appealing variant of traditional stainless steel. Unlike the conventional silver-toned stainless steel, the colored version undergoes a specialized coloring process, introducing a spectrum of hues to enhance its visual appeal. This transformative process not only adds vibrancy but also maintains the inherent durability and corrosion resistance that stainless steel is renowned for.

Colored Stainless Steel is achieved through various advanced techniques that modify the surface properties of stainless steel, creating a durable and vibrant finish. This innovative approach is not merely about aesthetics; it expands the functionality and applications of stainless steel, making it a sought-after choice in design and architecture.

Black Titanium Stainless Steel

Brown Stainless Steel

Tan Stainless Steel

Fuchsia Stainless Steel

Champagne Gold Stainless Steel

Rose Gold Stainless Steel

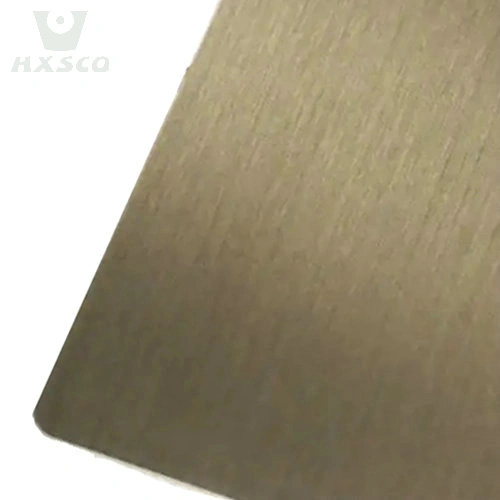

Bronze Stainless Steel

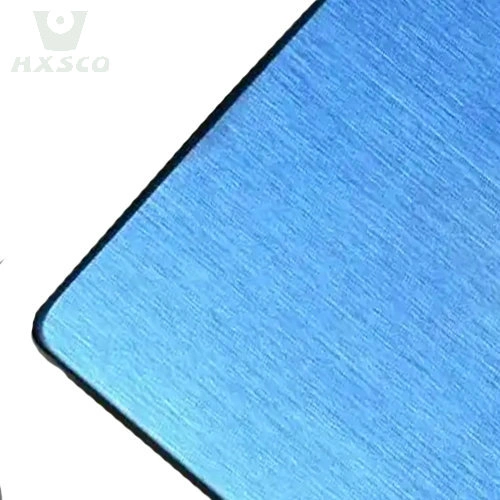

Blue Color Stainless Steel

Different Methods of Coloring Stainless Steel

Physical Vapor Deposition (PVD): PVD is a widely employed technique in achieving Colored Stainless Steel. In this method, a thin film of material, often a metal or metal compound, is deposited onto the stainless steel surface. This process results in a range of colors and finishes, offering both durability and design flexibility.

Electrochemical Coloring: This method involves the immersion of stainless steel in an electrolyte bath while applying an electric current. The controlled reaction between the metal and the electrolyte induces a color change on the surface, providing a durable and corrosion-resistant colored finish.

Powder Coating: Powder coating involves the application of a dry powder to the stainless steel surface, which is then heated to form a protective layer. This method not only enhances the visual appeal but also provides an additional layer of protection against environmental elements.

Chemical Coloring: Chemical processes, such as immersion in acid baths, can be employed to induce oxidation on the stainless steel surface. This controlled oxidation leads to the formation of a colored layer, offering a unique and textured finish.

These methods exemplify the versatility of Colored Stainless Steel, allowing for an extensive array of colors, patterns, and textures. The choice of method often depends on the desired aesthetic outcome, project specifications, and the expertise of the stainless steel manufacturer.

In the realm of architectural and design applications, the ability to offer Colored Stainless Steel opens up a myriad of possibilities. From vibrant façades to intricate interior elements, architects and designers are increasingly leveraging the versatility of colored stainless steel to create visually stunning and durable spaces.

In summary, Colored Stainless Steel represents a fusion of innovation and tradition, where the timeless strength of stainless steel meets the dynamic allure of color. As a Stainless Steel Manufacturer committed to quality and innovation, HXSCO ensures that its range of Colored Stainless Steel products not only meets but exceeds the expectations of clients worldwide. Whether for architectural marvels, industrial applications, or bespoke projects, Colored Stainless Steel from HXSCO is a testament to the limitless possibilities within the realm of stainless steel design.

Advantages Of Colored Stainless Steel

Durability and Corrosion Resistanc

One of the defining characteristics of Colored Stainless Steel is its unwavering commitment to durability and corrosion resistance. As a variant of traditional stainless steel, renowned for its robustness, colored stainless steel inherits these fundamental properties. The coloring process enhances, rather than compromises, the material’s innate ability to withstand harsh environmental conditions.

The protective oxide layer that naturally forms on stainless steel surfaces is not compromised during the coloring process. This ensures that Colored Stainless Steel maintains its resistance to corrosion, rust, and other forms of degradation. Whether used in exterior architectural applications or industrial settings, the longevity of colored stainless steel stands as a testament to its enduring strength.

At HXSCO, a leading Stainless Steel Manufacturer, our commitment to quality is reflected in every colored stainless steel product we offer. Clients can be assured that the vibrant aesthetics of our colored stainless steel go hand in hand with the robustness they expect from traditional stainless steel.

Aesthetic Appeal and Design Flexibility

Colored Stainless Steel transcends the boundaries of functionality, introducing a new dimension of aesthetic appeal and design flexibility. The versatility of colors and finishes opens up a realm of creative possibilities for architects, designers, and project stakeholders.

Architectural feats adorned with colored stainless steel panels become not just structures but statements of design prowess. The reflective surfaces, available in an array of colors, bring life and vibrancy to spaces, transforming the mundane into the extraordinary. Designers can play with contrasts, textures, and patterns, creating visually striking elements that leave a lasting impression.

As a Stainless Steel Manufacturer, HXSCO understands the importance of marrying form and function. Our range of colored stainless steel products is meticulously crafted to provide not only a durable and reliable material but also a canvas for creative expression. The adaptability of colored stainless steel allows architects and designers to bring their visions to life, making a bold statement in the world of design.

Environmental Benefits of Stainless Steel

Beyond its visual and structural advantages, Colored Stainless Steel aligns with environmentally conscious practices. Stainless steel, in general, is fully recyclable, and the coloring processes often involve environmentally friendly techniques.

The longevity of colored stainless steel contributes to sustainability by reducing the need for frequent replacements. As a durable and long-lasting material, it minimizes waste and resource consumption over time. Additionally, the recyclability of stainless steel aligns with circular economy principles, making it an eco-friendly choice for projects with environmental considerations.

HXSCO, as a responsible Stainless Steel Manufacturer, prioritizes sustainable practices. Our commitment to environmental responsibility is reflected not only in the quality of our colored stainless steel products but also in the processes involved in their creation. Clients choosing HXSCO’s colored stainless steel not only invest in aesthetics and durability but also contribute to a sustainable and eco-conscious approach to material selection.

In conclusion, the advantages of Colored Stainless Steel extend far beyond the visual realm. Its durability, aesthetic versatility, and environmental benefits position it as a material of choice for projects that demand a perfect amalgamation of strength, beauty, and sustainability. As a leading Stainless Steel Manufacturer, HXSCO takes pride in presenting colored stainless steel as a testament to innovation and excellence in the world of architectural and industrial design.

Applications Of Colored Stainless Steel

Architectural and Decorative Uses

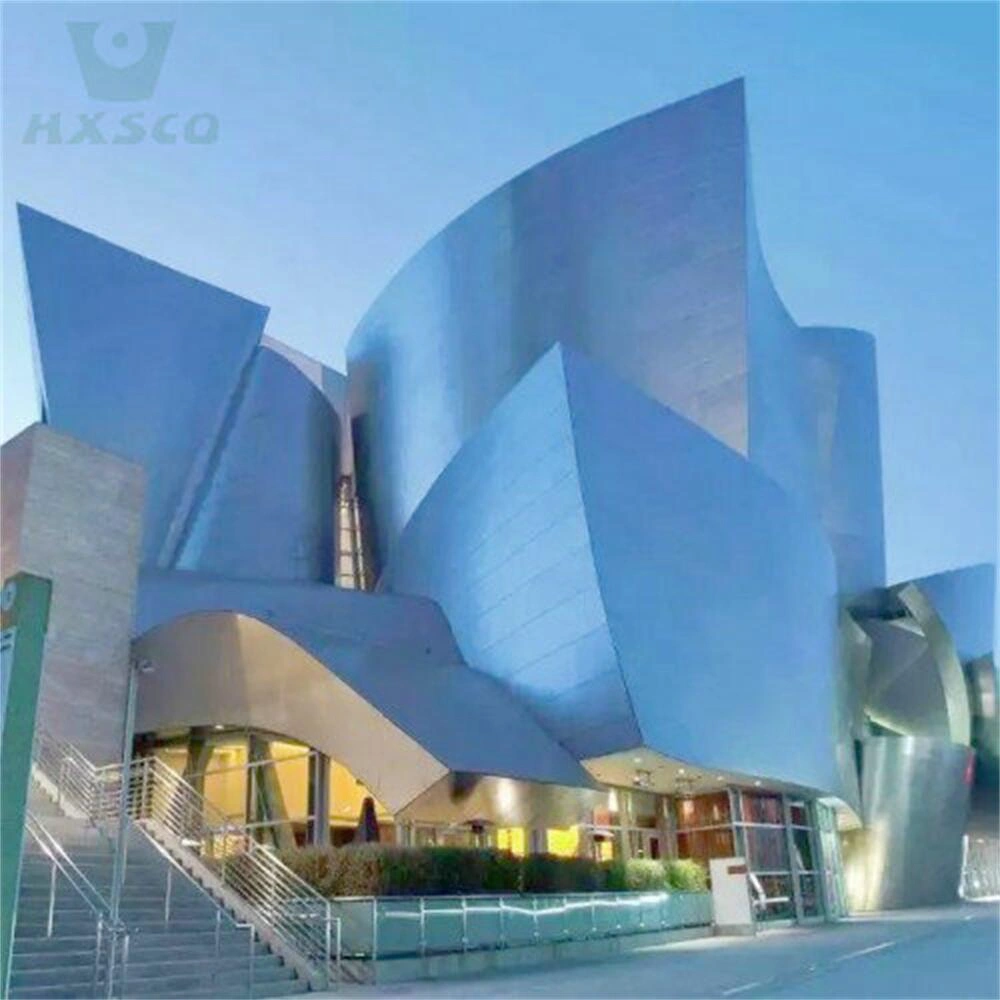

Colored Stainless Steel stands as a versatile and captivating choice for architectural and decorative applications, adding a touch of sophistication to structures and spaces. Architectural design, once confined to traditional materials, has been revolutionized by the introduction of colored stainless steel.

In architectural applications, the material finds its way into façades, cladding, and roofing, transforming buildings into artistic expressions. The reflective surfaces of colored stainless steel panels play with light, creating dynamic visual effects that evolve throughout the day. This versatility allows architects to explore a myriad of design possibilities, turning structures into captivating landmarks.

Decorative uses of colored stainless steel extend beyond the external façade. Interior spaces benefit from the material’s ability to evoke a sense of modernity and luxury. From elevator interiors to feature walls, designers utilize colored stainless steel to enhance the visual appeal of spaces, creating environments that are both functional and aesthetically pleasing.

Industrial Applications

The robustness of stainless steel finds a natural fit in various industrial applications, and the introduction of color extends its functionality beyond mere utility. Colored Stainless Steel is increasingly integrated into industrial settings for both aesthetic and practical purposes.

In industrial architecture, stainless steel is employed in the construction of warehouses, factories, and industrial facilities. The introduction of color adds a layer of sophistication to these structures, transforming utilitarian spaces into visually appealing environments. Additionally, the corrosion resistance of colored stainless steel ensures that it can withstand the challenges posed by industrial environments.

Beyond architectural elements, colored stainless steel finds application in industrial equipment and machinery. The material’s durability and resistance to corrosion make it an ideal choice for components that demand both strength and visual appeal. From machinery components to storage tanks, the integration of colored stainless steel adds a modern and sleek touch to industrial equipment.

Examples of Projects Featuring Colored Stainless Steel

Architectural Marvels:

Iconic skyscrapers featuring dynamic façades crafted from vibrant colored stainless steel panels.

Luxury hotels and resorts adorned with decorative elements, showcasing the material’s versatility.

Public Spaces:

Urban art installations and sculptures that leverage colored stainless steel for visual impact.

Transit stations and airports incorporating colored stainless steel for durable and aesthetically pleasing structures.

Industrial Facilities:

Warehouses and manufacturing plants integrating colored stainless steel into their architecture for a modern and cohesive look.

Machinery and equipment showcasing the marriage of functionality and design with colored stainless steel components.

These examples highlight the widespread adoption of Colored Stainless Steel in diverse projects, emphasizing its adaptability and appeal across various industries. As a Stainless Steel Manufacturer at the forefront of innovation, HXSCO takes pride in contributing to the success of such projects by providing high-quality colored stainless steel solutions.

In conclusion, the applications of Colored Stainless Steel extend from the realms of architecture to industrial landscapes, leaving an indelible mark on the visual and functional aspects of structures and equipment. HXSCO, as a reliable Stainless Steel Manufacturer, continues to play a pivotal role in shaping the contemporary landscape with its range of colored stainless steel products that embody both strength and aesthetic excellence.

Choosing The Right Colored Stainless Steel For Your Project

Choosing the appropriate Colored Stainless Steel for your project requires a thoughtful consideration of several key factors. Understanding these factors is essential in ensuring that the selected material aligns seamlessly with both aesthetic and functional requirements.

Application and Environment

Consider the intended use of the colored stainless steel. Is it for architectural façades, interior design, or industrial equipment? The environmental conditions, whether indoor or outdoor, play a crucial role in determining the required durability and corrosion resistance.

Color Stability:

Assess the color stability of the material over time. Quality colored stainless steel should maintain its vibrant hue and resist fading, ensuring a long-lasting and visually appealing result.

Maintenance Requirements:

Evaluate the maintenance demands of the chosen color and finish. Some colors may be more prone to showing fingerprints or scratches, and understanding the upkeep required is essential for the longevity of the aesthetic appeal.

Budget Considerations:

Balance aesthetic aspirations with budget constraints. Colored stainless steel comes in a variety of finishes, and the cost may vary accordingly. Understanding the budget constraints allows for the selection of an option that meets both aesthetic and financial goals.

Guidance on Choosing the Right Color and Finish

Navigating the vast spectrum of colors and finishes available in Colored Stainless Steel can be a stimulating yet challenging task. Here are some guidelines to aid in the decision-making process:

Harmony with Surroundings:

Consider the existing color palette of the surroundings. Choose a colored stainless steel finish that harmonizes with the architectural context or interior design scheme.

Design Intent:

Identify the design intent and mood of the project. Vibrant and bold colors may be suitable for contemporary and expressive designs, while muted tones can convey a sense of sophistication and timelessness.

Lighting Conditions:

Recognize the impact of lighting conditions on the perception of color. The appearance of colored stainless steel can vary under different lighting, so it’s advisable to evaluate color samples in various lighting environments.

Sample Testing:

Request samples of colored stainless steel to assess how they interact with the project’s surroundings. Viewing physical samples allows for a more accurate representation of color and finish.

How HXSCO Can Assist in the Decision-Making Process

At HXSCO, we understand that choosing the right Colored Stainless Steel is a pivotal step in the success of your project. Our commitment to providing comprehensive support goes beyond supplying high-quality materials. Here’s how HXSCO can assist in the decision-making process:

Expert Consultation:

Benefit from our team of experts who can provide guidance on selecting the most suitable colored stainless steel based on your project requirements. Our experience as a trusted Stainless Steel Manufacturer ensures that you receive informed and personalized advice.

Extensive Product Range:

Explore our extensive range of colored stainless steel options, including different colors, finishes, and textures. This diversity allows you to find the perfect match for your design vision.

Customization Services:

Tailor the colored stainless steel to your specific needs with our customization services. Whether it’s a unique color or a special finish, we work closely with clients to bring their design concepts to life.

Quality Assurance:

Trust in the quality assurance provided by HXSCO. Our commitment to delivering premium colored stainless steel ensures that your project benefits from both aesthetic excellence and structural integrity.

In conclusion, selecting the right Colored Stainless Steel involves a thoughtful evaluation of factors, informed decision-making on color and finish, and leveraging the expertise of a reliable Stainless Steel Manufacturer like HXSCO. With our support, your project can not only meet but exceed expectations, creating a lasting impact with the perfect blend of aesthetics and functionality.

Conclusion

In the realm of modern design and architecture, the transformative allure of Colored Stainless Steel has emerged as a beacon of innovation. As we navigate the possibilities of vibrant hues, dynamic finishes, and enduring strength, it becomes clear that this material transcends mere functionality—it embodies a fusion of artistry and resilience.

As you embark on your next project, envision a landscape where structures not only stand as testaments to durability but also resonate with captivating visual narratives. The palette of possibilities offered by colored stainless steel opens avenues for architectural and industrial expressions that are both timeless and contemporary.

At HXSCO, we stand as your dedicated partner, a reliable Stainless Steel Manufacturer committed to delivering excellence in every shade. Our colored stainless steel products are more than just materials; they are the embodiment of a vision—a vision where strength meets sophistication, where form harmonizes with function.

From the inception of your design concept to the final realization of your project, we offer more than just colored stainless steel; we offer expertise, customization, and a commitment to quality that sets your endeavor apart. Elevate your vision with the unparalleled vibrancy of colored stainless steel, and entrust your aspirations to a manufacturer that understands the nuances of both art and engineering.

In every project, the choice of materials defines the narrative. Choose Colored Stainless Steel from HXSCO, where innovation meets tradition, and where your vision finds its perfect reflection. Let the hues of possibility paint your success story, and let the strength of stainless steel lay the foundation for enduring excellence.

As you embark on this journey of design and distinction, remember: It’s not just stainless steel; it’s a canvas of potential, and it’s an embodiment of your vision. Choose HXSCO, your partner in shaping the future of design with the enduring elegance of Colored Stainless Steel.