HXSCO - Leader manufacturer in Electrical Steel

HXSCO is a leading electrical steel manufacturer in China. We have over 15 years of experience in the metal industry. With us, you'll get complete metal solutions. Our services cater to various sectors and provide one-stop solutions.

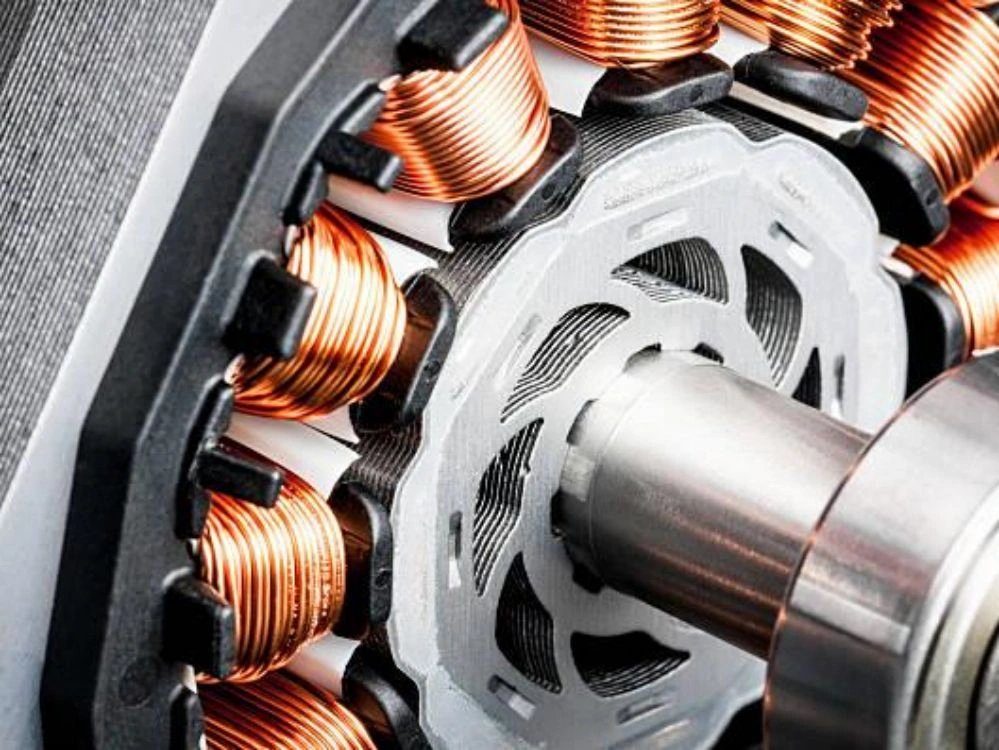

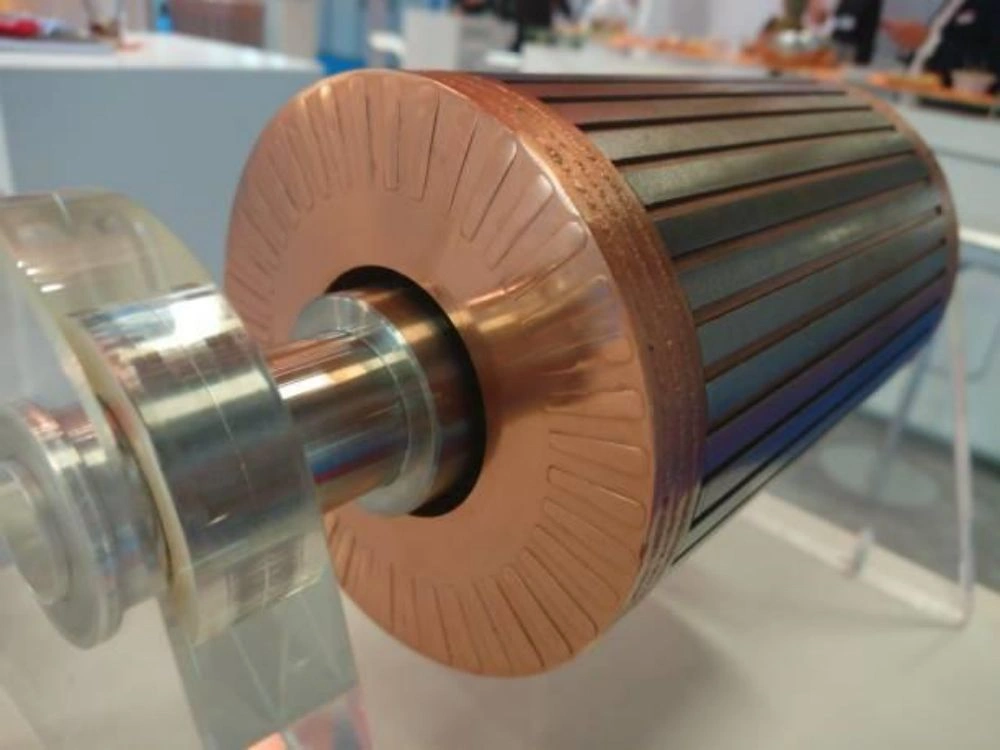

We are committed to excellence and innovation, ensuring top-quality products and services. Our range includes precision-engineered electrical steel products and customized solutions.

We operate state-of-the-art manufacturing facilities and employ skilled professionals. At HXSCO, customer satisfaction is our priority. Choose us for reliable and cost-effective metal solutions.