China Aluminum Wire Manufacturer

HXSCO is a leading aluminum wire manufacturer in China. We offer a comprehensive range of high-quality aluminum wires. Our products meet the most stringent standards of the global market. HXSCO is an SGS-ISO 9001-certified aluminum wire supplier. We adhere to the highest quality and reliability standards. Our team follows each of those standards during all the wire production processes.

HXSCO’s aluminum wires are used in various applications in different sectors. For example, power, aerospace, and transportation. Our products are known for their consistent quality, reliable performance, and service life. Aluminum wire has become the first choice for many high-quality material applications.

Do you need standard or custom aluminum wire? HXSCO has the features and expertise to excel. We offer the highest quality aluminum wire at competitive wholesale prices. Contact us today to learn more about our aluminum products and services. Our SGS-ISO 9001-certified aluminum products allow you to buy with confidence.

Contact Us| Aluminum Wire Grade | Diameter Range (mm) | Tensile Strength (MPa) | Elongation(%) | Standard |

|---|---|---|---|---|

| 1100 | 0.10 – 5.00 | 75 – 95 | 22- 35 | ASTM B211 |

| 1350 | 0.10 – 5.00 | 90 – 130 | 18 – 30 | ASTM B230 |

| 3003 | 0.10 – 5.00 | 110 – 140 | 20 – 30 | ASTM B233 |

| 5052 | 0.10 – 5.00 | 210 – 230 | 10 – 20 | ASTM B317 |

| 6061 | 0.10 – 5.00 | 240 – 270 | 8 – 15 | ASTM B316 |

| 7075 | 0.10 – 5.00 | 500 – 570 | 5 – 10 | ASTM B317 |

Aluminum wire specification

Types Of Aluminum Wire

Among the Professional China Aluminum Wire Suppliers

Alloys

1000 Series Aluminum Wire: This series primarily consists of pure aluminum. It is characterized by its excellent corrosion resistance and high electrical conductivity. 1000-series aluminum wire is often chosen for applications with paramount electrical conductivity, such as electrical transmission and power distribution.

5000 Series Aluminum Wire: Aluminum alloys in the 5000 series, like 5052 and 5086, contain magnesium as the primary alloying element. These wires offer improved strength and are particularly suitable for marine and architectural applications due to their resistance to saltwater corrosion.

6000 Series Aluminum Wire: This series includes alloys like 6061 and 6063, which combine magnesium and silicon. 6000 series aluminum wires are renowned for their versatility, making them suitable for various applications, including construction, automotive components, and aerospace.

7000 Series Aluminum Wire: Alloys within the 7000 series, such as 7075, are known for their exceptional strength. These wires are often utilized in aerospace and high-stress applications where durability and resilience are crucial.

Tempers

O (Soft) Temper: Soft-tempered aluminum wire is highly malleable and easy to bend and shape. It is commonly used in craft and DIY projects, where flexibility is essential.

H (Half-Hard) Temper: Half-hard aluminum wire balances flexibility and rigidity. It is suitable for applications requiring some degree of stiffness, such as jewelry making and structural components in construction.

T (Hard) Temper: Hard-tempered aluminum wire offers high strength and rigidity. It is often found in demanding applications like aerospace, where structural integrity is paramount.

Shapes of aluminium wire

- Round aluminum wire: This is the most common shape, with a round cross-section. Its usage is common in various electrical, electronic, and telecommunications applications.

- Rectangular and flat aluminum wires: They have a specific width and thickness. Their utility is standard in applications requiring various particular shapes and sizes. Examples include motor windings, cable cores, etc.

- Other Polygonal Aluminum Wires: These wires can be of different shapes, including squares and triangles. They may be required for specific occasions or special applications.

- It is important to note that aluminum wires have very specific shapes and sizes. These specifications of shapes and sizes make them tailored to the needs of their applications.

Aluminum wire manufacturing process

Raw material preparation: It starts with aluminum ingots, which play a crucial role in producing aluminum wires. The ingots are heated, melted, and refined to obtain pure aluminum.

Extrusion forming: This process involves heating aluminum to the appropriate temperature. The aluminum billet is extruded into the required shape. Those shapes include aluminum rods or profiles. This process is done with the help of an extruder.

Drawing: The extruded aluminum rods or profiles undergo several drawing processes. Those happen in a drawing machine to progressively refine the aluminum wire. This process gives wires the required diameter while improving the surface smoothness.

Subsequent treatment: Depending on the requirements, additional treatment may be necessary. These can include polishing, heat treatment, and surface coating. These will enhance the properties of the aluminum wire to meet application requirements.

Advantages of Aluminum Wire

Excellent conductivity

Aluminum is an excellent conductive material. It imparts excellent conductivity to aluminum wires as well. Notably, aluminum wire is slightly more resistant than copper. It is also lighter in weight and cost, making it widely used in electricity. Many electronics and communication devices utilize these wires.

Lightweight

Aluminum wire is much less dense than copper, making it lighter in weight. In power transmission, using aluminum wire reduces the weight of the line. Not only this, but it also reduces material and installation costs. Equipment using aluminum wires undergoes lesser load.

Good corrosion resistance

This wire is prone to form a dense aluminum oxide film on its surface. It effectively prevents further oxidation or corrosion of the wire. This excellent corrosion resistance allows the aluminum wire to maintain stable performance.

Enhancement by alloying components

Certain types of aluminum wire contain alloying components. These alloying components enhance the tensile strength and ductility of aluminum wire. For example, 7075 aluminum wire has a tensile strength of up to 524 Mpa and a yield strength of 455 Mpa.

when was aluminum wire used

Aerospace industry

Aluminum wire has two key features: it conducts well and is light. Because of this, it’s widely used in the aerospace industry for wire. Its light weight helps cut the aircraft’s weight and improve fuel efficiency. Its high conductivity ensures efficient signal transmission.

.

Transmission lines

Aluminum wire has excellent electrical conductivity. This makes it an ideal choice for transmission lines. Its lightweight nature reduces stress on the supporting structure and allows longer spans between towers. Additionally, its corrosion resistance ensures longevity even in harsh outdoor environments.

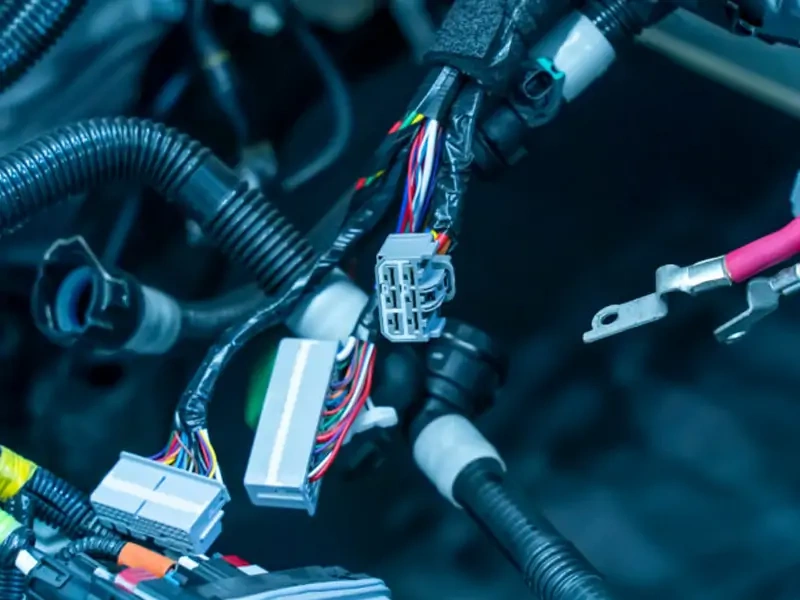

Automotive wiring harness

Aluminum wire is now used more in automotive wiring because it is lightweight. By using aluminum instead of copper, vehicles can reduce weight, improving fuel efficiency and reducing emissions. In addition, aluminum’s corrosion resistance ensures the reliability of the vehicle’s electrical system.

.

High-strength aluminum alloy for ships

Aluminum wire is reinforced with an alloy. It is used in ship applications, like shipbuilding and offshore structures. These alloys offer high strength and corrosion resistance. They are suitable for use in harsh marine environments. Additionally, their lightweight nature helps reduce the overall weight of marine structures, helping to improve efficiency and performance.

Packing & Shipping of Aluminum Wire

Packaging method:

- Coil packing: suitable for long aluminum wire, space-saving, easy to store and transport.

- Straight packing: suitable for short aluminum wires. They show the length and shape of aluminum wires.

Packaging material: Choose cardboard, plastic film, or bubble wrap based on the wire’s characteristics. This will ensure that aluminum wire is not damaged during shipping or transportation.

Transport service:

- Mode of transport: According to the quantity and volume of wires, choose land, sea, or air transport.

- Safety measures: Fix the wire, shockproof it, and moisture-proof it. These safety measures will ensure its safe arrival.

Additional services:

- Customized packaging: Offer customized packaging solutions according to customers’ needs. However, ensure that the customization is based on the characteristics of aluminum wire.

- Full tracking: This feature tracks aluminum wire transport status in real time. It might sound unnecessary, but it ensures better customer response. They (customers) remain informed about the latest developments.

- Rapid Response: Respond quickly to problems in packaging and transport and provide solutions.

We are committed to providing safe and efficient packaging and transport services for aluminum wire. We aim to offer 100% customer satisfaction as an aluminum wire company.

FAQs About Aluminum Wire Supplier – HXSCO

Aluminum and copper wires are both commonly used for electrical wiring. Each has its characteristics and benefits.

Conductivity:

- Copper: Superior conductivity, resulting in less power loss and better performance.

- Aluminum: Lower conductivity compared to copper, leading to more power loss.

Cost:

- Copper: More expensive than aluminum.

- Aluminum: Cost-effective alternative to copper.

Weight:

- Copper: Heavier than aluminum.

- Aluminum: Lighter, making it easier to handle and install.

Corrosion Resistance:

- Copper: Highly resistant to corrosion, suitable for various environments.

- Aluminum: Susceptible to corrosion and may require additional protection in certain conditions.

Thermal Expansion:

- Copper: Minimal thermal expansion, maintaining stable connections.

- Aluminum: Greater thermal expansion, potentially causing connection issues over time.

Compatibility:

- Copper: Widely compatible with existing systems and devices.

- Aluminum: It requires special connectors or treatments for proper installation and performance.

Before choosing between aluminum and copper wire, consider the factors mentioned above. They will help you make wise decisions based on your needs and preferences. Ultimately, you will get the best performance and cost savings.

The aluminum wire size for a 100-amp service should be based on the wire’s current capacity. Typically, the current carrying capacity of aluminum wire is proportional to its size. According to the electrical code of practice, aluminum wire can pass a current of 4 amperes per square millimeter. So, for 100 amps, pick an aluminum wire with a 25 mm² cross-section. This will ensure its proper operation.

However, the distance and method of transmission for aluminum wire are also crucial. They affect the current carrying capacity of the wire. For example, bare aluminum wires may have a higher current carrying capacity. Contrarily, insulated aluminum wires may have a lower current carrying capacity. In practice, you may need to adjust the size of aluminum wires. Doing this will better suit different situations.

At the same time, their current carrying capacity is also essential. You must consider this capacity while selecting aluminum wires. Besides that, you must also consider their strength, corrosion resistance, and other properties. Understanding and analyzing the installation method is also crucial.

In summary, for a 100 amp current, choose 25 sq mm aluminum wire. This is recommended for aluminum wire’s cross-section specification. However, you must select the specific size based on multiple factors. These include how the wire transmits, its performance, and how it is installed.

For a 200 amp service, the recommended aluminum wire size for the entrance conductors is usually 2/0 AWG. However, this recommendation may vary based on multiple factors. These factors include the wire run length, voltage drop, and local electrical codes. You must consult with a qualified electrical engineer or contractor. They will determine the appropriate wire size for your specific application. Determination of these factors will ensure compliance with all safety standards and requirements.