Stainless Steel Sheet Manufacturer in China

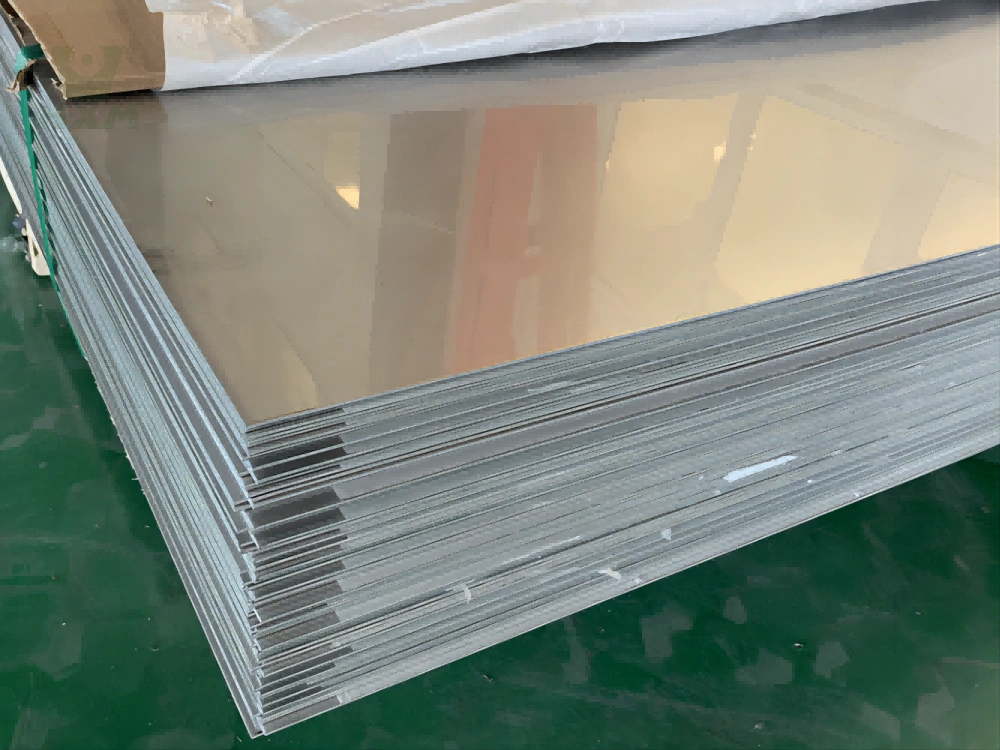

HXSCO is China's leading stainless steel sheet manufacturer. We offer a comprehensive range of high-quality stainless steel metal sheets. Our products meet the most stringent standards of global markets. HXSCO is a stainless steel sheet supplier with SGS-ISO 9001 certification. We adhere to all SS sheet production processes' highest quality and reliability standards.

HXSCO's stainless steel sheets are widely used in construction, automobiles, and manufacturing. Our products are known for their consistent quality, reliable performance, and service life. Stainless steel sheet has become the first choice for many high-quality material applications.

Do you need standard stainless steel sheets or custom stainless steel sheets? HXSCO has excellent capabilities and professional knowledge. We offer the best quality SS sheets at competitive wholesale prices. Contact us today to learn more about our stainless steel sheet products and services. Our SGS-ISO 9001-certified SS sheet metal allows you to buy with confidence.

Contact Us| Stainless Steel Sheet Specifications | |

|---|---|

| Thickness | 0.3~3.0 mm |

| Width | 1000, 1219, 1250, 1500, 1524, 1800, 2000 mm |

| Length | 2000, 2438, 2500, 3000, 3048, 6069, 10000 mm |

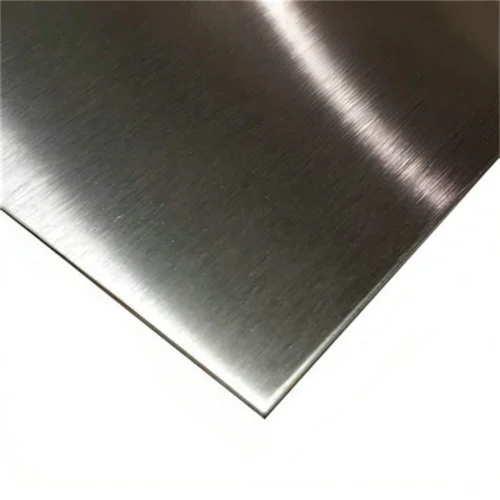

| Finish | No.1, 2B, BA, No.3, No.4, No.5, No.8, HL, Etching, SB, Back Pass, Ti-coating |

| Protect Film | PVC, PE, LASER-PVC, Black-White, Blue-White, 20um-120um |

| Origin | China |

| Shipping | 3-15 Days |

| Price | Depending on the order |