Types Of Brass Bar

Brass Round Bar

Brass Square Bar

Brass Rectangle Bar

Brass Hexagon Bar

Brass Flat Bar

🔘HXSCO maintain close cooperation with many well-known stainless steel mills. Among them, TISCO, YUSCO, LISCO, JISCO, POSCO, ZPSS, QPSS and Baosteel are our long-term cooperative steel mills. We can trade in excess of 13 million tonnes of stainless steel each year, supplying and sourcing over 100,000 tonnes of stainless steel stock to our global customers.

🔘🟡HXSCO has a large stock selection of brass round bars and bars ranging from 3.2mm to 6.3mm in diameter and up to 3m in length. This brass rod is made of CZ121, which has good corrosion resistance and good machinability.

🔘🟡🟠360 Brass Square Bar is an ideal choice for applications that require an attractive appearance and corrosion resistance. Brass square bars are easily drilled, machined and sawed.

🔘🟡🟠Brass Hex Bars are commonly used in corrosive environments, mechanical or architectural applications, gear or lock assemblies, and decorative projects. ASTM B16 360 Brass is the standard specification for free-cutting brass rods, rods, and other shapes.

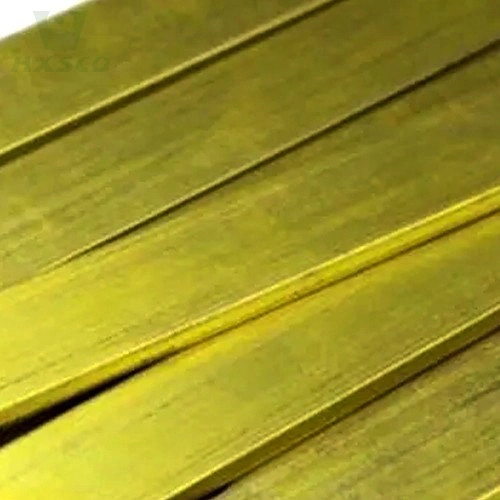

🔘🟡🟠Different zinc content will also have different colors. Zinc content of 18%-20% will be reddish-yellow, while zinc content of 20%-30% will be brown-yellow. In addition, brass has a unique sound when struck, so Eastern gongs, cymbals, bells, horns and other musical instruments, as well as Western brass instruments are all made of brass bar.

Features And Benefits Of Brass Bar

GOOD PROCESSING PERFORMANCE

Brass bar are easy to process and form, and can be processed into desired shapes by various methods such as cutting, drilling, cold forging and hot forging.

GOOD CORROSION RESISTANC

Brass bar have good corrosion resistance and can resist the erosion of many chemicals. They can be used to make water pipes, valves and pipes, etc.

HIGH TEMPERATURE RESISTANCE

Brass bar have good plasticity, can be easily bent and stretched into desired shapes, and can be used to manufacture various precision parts. Brass bar have good thermal conductivity, can transfer heat quickly, and can be used to manufacture parts such as radiators and heaters.

GOOD ELECTRICAL CONDUCTIVITY

Brass bar have good electrical conductivity and can be used to make components of electronic devices such as electrical connectors and circuit boards.

GOOD WEAR RESISTANCE

Brass bar have good wear resistance, can withstand friction and wear, and can be used to manufacture bearings, gears and connectors, etc.

GOOD ELECTRICAL CONDUCTIVITY

Brass bar have good high temperature resistance, can work in high temperature environments, and are not easy to deform or melt.

Application Of Brass Bar

Brass bar are made of copper and zinc mixed in a certain proportion, and have excellent mechanical properties and processing properties. Therefore, Brass bar are widely used in many fields, and the following are a few of them:

Electrical and electronic fields

Brass bar have good electrical and thermal conductivity, so they are widely used in the manufacture of conductive parts of electrical and electronic equipment, such as plugs, sockets, terminals, cables and circuit boards, etc.

Machining field

Brass bar have good processing performance and plasticity, so they can be used to manufacture various mechanical parts, such as shafts, gears, screws, gaskets, etc.

Construction and decoration fields

Brass bar have good corrosion resistance and aesthetics, so they are widely used in construction and decoration materials, such as door handles, handles, hinges, door locks, windows and door and window accessories, etc.

The field of manufacturing musical instruments

Brass bar can be used to manufacture various musical instruments, such as trumpets, trombones, French horns, tubas, bronze drums, cymbals, etc.

Medical device field

Brass bar can be used to manufacture medical devices, such as scalpels, medical clips, pliers, etc.

Production Process Of Brass Bar

Raw material preparation: The main raw materials of Brass bar are copper and zinc, which are mixed by the Brass bar supplier in a certain proportion and smelted. During the smelting process, it is also necessary to add some auxiliary agents, such as oxygen scavenger, desulfurizer, etc., to ensure the purity and quality of the molten pool.

Step 1 Melting

The Brass bar supplier puts the prepared raw materials into a high-temperature furnace, heats them to a high enough temperature to melt them, and mixes them evenly. During the smelting process, a series of tests and inspections are carried out to ensure that the composition of the molten pool meets the requirements.

Step 2 Casting

The Brass bar supplier pours the molten pool into a mold, allowing it to solidify into a rod. During the casting process, the Brass bar supplier should control the temperature and pouring speed to avoid defects such as air bubbles and shrinkage cavities inside the rod.

Step 3 Heat treatment

The Brass bar supplier heat-treats the cast rod to obtain better physical and mechanical properties. Heat treatment methods include annealing, quenching, tempering and the like.

Step 4 Finishing

Brass bar suppliers will finish heat-treated rods to meet certain size and accuracy requirements. Finishing methods include drawing, extrusion, rolling, and the like.

Step 5 Surface treatment

The Brass bar supplier will carry out surface treatment on the processed Brass bar to remove surface oxides, rust, etc., to make the surface smooth and beautiful. Surface treatment methods include grinding, polishing, coating and so on.

Step 6 Inspection and packaging

The Brass bar supplier conducts quality inspection on the processed Brass bar to check whether their dimensions, surface finish, chemical composition, etc. meet the requirements. Finally packed and labeled ready for sale and shipping.

Cleaning And Maintenance Steps For Brass Bar

1. Use a mild detergent and a soft cloth. Some household cleaners, such as white vinegar or lemon juice, can be used by mixing the cleaner with water and wiping the surface of the Brass bar with a soft cloth.

2. Avoid abrasive cleaners or harsh cleaning tools such as steel wool, which can scratch the brass surface.

3. Soak the Brass bar in warm water, dampen a soft cloth and wipe the brass surface. It can be wiped repeatedly several times until the surface of the Brass bar becomes bright.

4. If there is stubborn dirt on the surface of the Brass bar, it can be gently wiped with a soft brush. It should be noted that the brush should not be too hard, so as not to scratch the surface.

5. Wipe the surface of the Brass bar dry to avoid moisture remaining on the surface.

6. Use a special brass care agent such as wax, polish or varnish. These products can help protect the surface of brass from oxidation and contamination, keeping it looking bright.

7. Avoid exposing the Brass bar to a humid environment for a long time to avoid oxidation and rust.

In conclusion, the key to caring for your Brass bar is gentle cleaning and regular maintenance. This will keep the Brass bar looking bright, durable and extend their life.

How To Choose Brass Bar Suppliers?

To choose reliable brass bar suppliers you need to consider the following factors:

Quality: Make sure that the Brass bar provided by the brass bar suppliers meet your quality requirements. This includes material composition, size and appearance, etc.

Price: Compare prices from different brass bar suppliers to make sure you’re getting a fair price without sacrificing quality.

Reliability: choose reliable brass bar suppliers who can deliver on time and guarantee a stable supply.

Service: The service provided by brass bar suppliers is also an important aspect of selection, including pre-sales consultation and after-sales service.

Reputation: Choose brass bar suppliers with a good reputation, you can find out by checking its historical transaction records, customer evaluations, etc.

It is suggested that you can choose brass bar suppliers in the following ways:

Online search: Search for relevant keywords such as “brass bar suppliers” on major search engines, and then browse the brass bar suppliers’ website to learn about its product quality, price, service and other information.

Participate in exhibitions: Participating in relevant exhibitions allows you to meet brass bar suppliers face-to-face, learn about their products and services, and compare with other brass bar supplierss.

Recommendation: You can ask friends in the same industry or other brass bar suppliers for their recommended brass bar suppliers, and learn about their purchasing experience and evaluation.

No matter which way you choose, you must pay attention to verifying the credibility and service level of the brass bar suppliers, and conduct sufficient investigation and comparison before choosing.

Conclusion

Brass bar is a metal material made of copper and zinc alloy, which is environmentally friendly and sustainable. Environmentally friendly, the Brass bar is a recyclable material, which means it can be recycled and reused, reducing the need for natural resources. In addition, the manufacturing process of Brass bar is relatively simple, does not generate a lot of pollutants and waste, and has a small impact on the environment.

In terms of sustainability, the Brass bar has good durability and strength, which means it can be used for a long time without failure. In addition, the raw materials copper and zinc used in the production of the Brass bar are both renewable resources, so they can be recycled without harming the environment.

In conclusion, Brass bar, as a recyclable and sustainable metal material, has a good performance in terms of environmental protection and sustainability.