HXSCO - Reliable Carbon Steel manufacturer in china

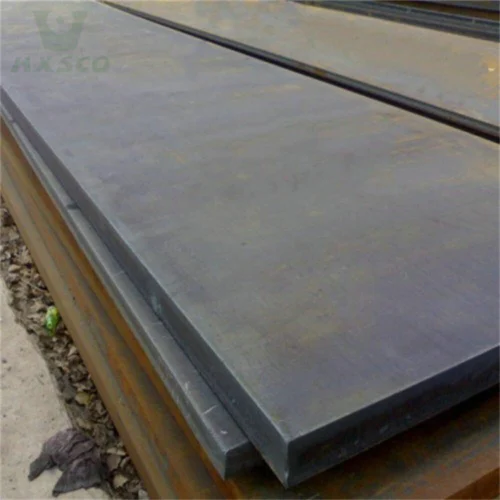

HXSCO is China's top carbon steel manufacturer, providing high-quality carbon steel globally. With over 15 years of expertise in the metal industry, it has become China's most trusted carbon steel supplier.

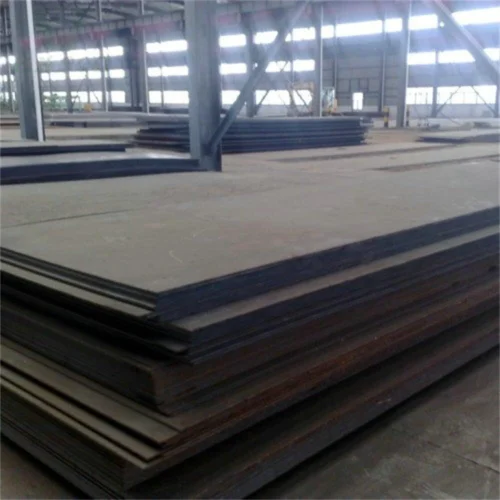

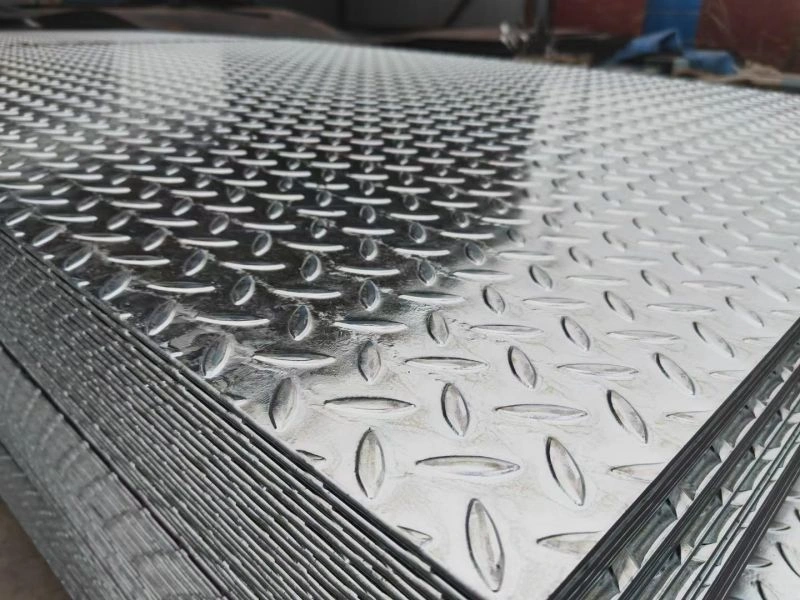

Our carbon steel products range from low to high carbon to suit every need. Strong and cost-effective, these carbon steel materials are ideal for construction, automotive, and outdoor use.

HXSCO's strict quality control has won praise from customers. We also provide professional carbon steel wholesale services and offer a comprehensive range of carbon steel products. Our company promises to provide high-quality products and services to create a better future together.