Knowing the thickness of metal sheets is important in many industries. The reason is that manufacturers cut and fabricate the metals according to thickness. The sheet metal gauge chart is the system that helps us know the exact thickness of the metal sheets.

However, the concept of this gauge chart is at least understood. Knowing this is essential for both the manufacturers and the customers. In this guide, I will explain the meaning and importance of metal gauge charts concerning different metals.

Also Read: Explore the Melting Points Of Metals

What Do Sheet Metal Gauges Mean?

The sheet metal gauge gives us the exact measurement of the thickness of different metal sheets. The lower gauge number indicates that the metal sheet is thicker and vice versa. It helps us understand the size measurement of metal sheets, etc.

Notably, the metal gauge chart indicates the thickness (measurement) in two units, i.e., inches and millimeters. However, the trick is that the gauge number of different metals can have different thicknesses in inches or millimeters.

For example, the ten gauge number for a carbon steel sheet indicates a thickness of 0.1345 inches. The same gauge number for aluminum and stainless steel indicates a thickness of 0.1019 and 0.1406, respectively. It shows that the gauge number is independent and can have different thicknesses in different metal sheets.

Metal gauge charts are commonly used in many industries, such as automobile, aerospace, and construction. The engineers measure the thickness of each metal sheet before cutting or bending it. Knowing the thickness of metal sheets helps them to know how much energy or time they will need to cut that metal.

Where Did Sheet Metal Gauges Come From?

Interestingly, the metal gauge measurement system originated in the 1900s. At that time, the wire makers and sellers sold metal wires by weighing them. However, this was not an accurate measurement. Buyers needed help buying the specific thickness of the wire or metal sheet.

Similarly, the wire drawers (those who draw metal sheets into the wires) also found it hard to categorize the wires of different thicknesses. They also needed to determine the customer’s demand from the perspective of wire size and thickness.

The drawer began addressing this issue by producing and selling wire based on the number of draws it underwent. A single draw meant a thicker sheet, while multiple draws indicated a thinner one. Each draw was named a gauge. It is a French word that means ‘measurement.’

So, if the wire underwent multiple draws, it would have a greater gauge number and thinner. Similarly, if the wire has undergone one or two draws, it will have a smaller gauge number and be thicker. One draw is equal to one gauge. A wire with a ten gauge number indicates it has undergone ten draws.

Additional Information: The drawers are used to draw metal. Drawing is a process in which the metal sheet is stretched, and thin wires are made. Each stretch is called a draw. More draws in the drawing of metal means that the wire will be thin and vice versa.

How to Read & Use a Sheet Metal Gauge Chart?

Understanding the metal gauge chart is very straightforward. It mainly consists of three columns. The first column indicates the gauge number, which is different for metal sheets. The second and third columns represent the thickness of that metal sheet in inches and millimeters, respectively.

However, there are two basic rules that you must understand to use the chart correctly. Those rules or principles include:

- The gauge number down the order increases, but it is independent. In front of each gauge number, you’ll see the thickness in inches and millimeters.

- Down the order in the gauge chart, the gauge number increases, but the thickness of the metal sheet decreases. It means the greater the gauge number, the thinner the metal. For example, a metal sheet with gauge number 18 will be thinner than gauge number 14.

The engineer immediately estimates the thickness of the metal sheet just by seeing the gauge numbers of metals. However, if you are new to charting, don’t worry; you can match the gauge number of metal with the second column and get the exact thickness of that metal.

Metal Gauge Chart of Stainless Steel

In the above section, I have explained the simple way of understanding the sheet metal gauge chart. However, to help those new to this measurement, I will write the whole chart for stainless steel so that you know how this chart works, giving you an exact thickness measurement.

| Gauge Numbers | Thickness in Inches | Thickness in MM |

| 7 | 0.1875 | 4.76 |

| 8 | 0.1719 | 4.37 |

| 9 | 0.1563 | 3.97 |

| 10 | 0.1406 | 3.57 |

| 11 | 0.1250 | 3.18 |

| 12 | 0.1094 | 2.78 |

| 13 | 0.094 | 2.4 |

| 14 | 0.0781 | 1.98 |

| 15 | 0.07 | 1.8 |

| 16 | 0.0625 | 1.59 |

| 17 | 0.056 | 1.4 |

| 18 | 0.0500 | 1.27 |

| 19 | 0.044 | 1.1 |

| 20 | 0.0375 | 0.95 |

| 21 | 0.034 | 0.86 |

| 22 | 0.0312 | 0.79 |

| 23 | 0.028 | 0.64 |

| 24 | 0.025 | 0.64 |

| 25 | 0.022 | 0.56 |

| 26 | 0.019 | 0.48 |

| 27 | 0.017 | 0.43 |

| 28 | 0.016 | 0.41 |

| 29 | 0.014 | 0.36 |

| 30 | 0.013 | 0.33 |

The table shows that the stainless steel sheet with gauge number 7 has a thickness of 0.1875 inches. Down the order, the stainless steel having gauge number 8 has a thickness of 0.1719. The same pattern goes on till the end of the chart.

It indicates that the gauge number of a metal sheet and its thickness are inversely proportional. The thicker sheet will have a greater lesser gauge number, and the thinner one will have a greater gauge number.

Metal Gauge Chart of aluminium

The relation between the gauge number of metal and the thickness of the sheet will always be the same (inversely related to each other). However, the gauge number of different metals can have different thicknesses. To help you understand this, I am providing an aluminum metal sheet chart.

Consider gauge number 16 for the stainless steel and aluminum metal sheets. The 16 gauge-numbered stainless steel sheet has a thickness of 0.0625 inches. In contrast, the 16 gauge-numbered aluminum sheet has a thickness of 0.0508 inches. The trend is the same for all the gauge numbers in both metal sheets.

| Gauge Numbers | Thickness in Inches | Thickness in MM |

| 6 | 0.162 | 4.1 |

| 7 | 0.1443 | 3.67 |

| 8 | 0.1285 | 3.26 |

| 9 | 0.1144 | 2.91 |

| 10 | 0.1019 | 2.59 |

| 11 | 0.0907 | 2.3 |

| 12 | 0.0808 | 2.05 |

| 13 | 0.072 | 1.8 |

| 14 | 0.0641 | 1.63 |

| 15 | 0.057 | 1.4 |

| 16 | 0.0508 | 1.29 |

| 17 | 0.045 | 1.1 |

| 18 | 0.0403 | 1.02 |

| 19 | 0.036 | 0.91 |

| 20 | 0.032 | 0.81 |

| 21 | 0.028 | 0.71 |

| 22 | 0.025 | 0.64 |

| 23 | 0.023 | 0.58 |

| 24 | 0.02 | 0.51 |

| 25 | 0.018 | 0.46 |

| 26 | 0.017 | 0.43 |

| 27 | 0.014 | 0.36 |

Metal Gauge Chart of Mild Steel

The gauge number independence and the trend of thickness increase are universal and hold for all metals. If you are looking for the thickness of different steel sheets, don’t worry; I will provide you with a complete steel gauge chart in the upcoming section. However, the rules are similar to those in the two charts above.

| Gauge Numbers | Thickness in Inches | Thickness in MM |

| 3 | 0.2391 | 6.07 |

| 4 | 0.2242 | 5.69 |

| 5 | 0.2092 | 5.31 |

| 6 | 0.1943 | 4.94 |

| 7 | 0.1793 | 4.55 |

| 8 | 0.1644 | 4.18 |

| 9 | 0.1495 | 3.80 |

| 10 | 0.1345 | 3.42 |

| 11 | 0.1196 | 3.04 |

| 12 | 0.1046 | 2.66 |

| 13 | 0.0897 | 2.28 |

| 14 | 0.0747 | 1.90 |

| 15 | 0.0673 | 1.71 |

| 16 | 0.0598 | 1.52 |

| 17 | 0.0538 | 1.37 |

| 18 | 0.0478 | 1.21 |

| 19 | 0.0418 | 1.06 |

| 20 | 0.0359 | 0.91 |

| 21 | 0.0329 | 0.84 |

| 22 | 0.0299 | 0.76 |

| 23 | 0.0269 | 0.68 |

| 24 | 0.0239 | 0.61 |

| 25 | 0.0209 | 0.53 |

| 26 | 0.0179 | 0.45 |

| 27 | 0.0164 | 0.42 |

| 28 | 0.0149 | 0.38 |

| 29 | 0.0135 | 0.34 |

| 30 | 0.0120 | 0.30 |

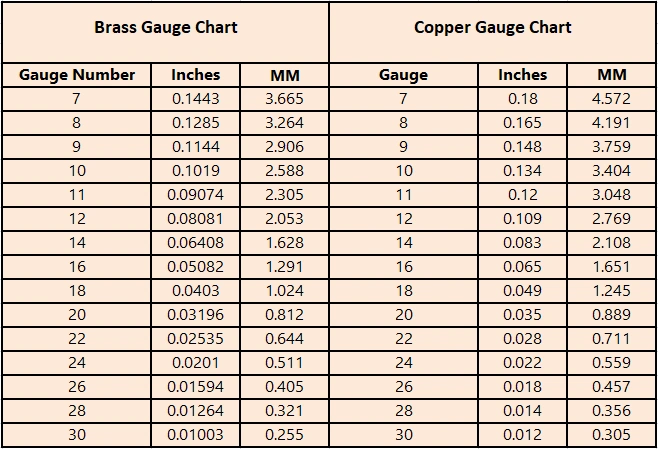

Metal Gauge Chart of Brass & Copper

Why Do Sheet Metal Gauges Matter?

The metal gauge chart is very important because it gives us the exact thickness measurement of any metal sheet. This gauge system makes it easier to know the exact thickness of metal sheets and solve thickness measurement problems.

Engineers rely on knowing the thickness of a metal sheet, which is particularly crucial during the stamping, forming, welding, and cutting processes. Precision is indispensable in achieving accurate results and maintaining the quality of the final product.

When they know the thickness of the sheet, they estimate the energy and time they will have to spend on the work. The thickness of the metal also helps them know about its effectiveness. A thicker metal is more durable.

Someone aiming to make something strong prefers a thicker sheet, and vice versa. This sheet metal gauge chart is there to help know the exact thickness of the metal.

Suppose they need a stainless steel sheet with a thickness of 4.37 millimetres; by the gauge chart, they will easily choose the stainless steel with gauge number 12. This chart makes it easy to identify the exact thickness of the metal.

Confusion between Sheet Metal Gauges & Grades

Metal gauges and grades have distinct meanings and play crucial roles in metalworking. Both terms are essential in ensuring the quality and performance of metal products; however, they mean different worlds.

Metal gauges are the measurement unit of metal sheets that allows you to know the thickness of any metal sheet in inches or millimetres. The metal grades are different metal types with different chemical compositions and qualities.

Different metals have different grades that vary from the metal itself in many ways. For example, steel has over 3500 different grades. Similarly, aluminum also has different grades. These grades differ in terms of quality and composition from the parent metal.

The metal gauge of any metal sheet tells us about its thickness. On the other hand, the grade tells us about the quality, composition and type of metal. Both of these two terms are different and serve different purposes.

14 Gauge or 16 Gauge Steel – Which is More Thicker?

The lower gauge number of any metal indicates that it is thicker. In 14 vs 16 gauge steel, the 14 gauge steel sheet will be thicker than the 16 gauge steel sheet. As we go downward in the metal gauge chart, the gauge number increases and the thickness decreases.

To be more precise, the 14 gauge steel has a thickness of 0.0747 inches. On the other hand, the 16 gauge number is 0.0598 inches thicker. If we consider 18 gauge steel, it will be even thinner. To further understand this, you should check the chart for different metals I have already given in the above section.

Although I have explained the topic in detail, some recurring questions are from newcomers unfamiliar with the gauge system. In the section below, I will answer those questions briefly.

FAQs of Sheet Metal Gauge

1- How thick is 20 gauge sheet metal?

The question is incomplete as the metal name is not mentioned. Each metal has its metal gauge chart. On that chart, the 20 gauge number will indicate the thickness of that metal in inches and millimetres. To understand more, please check the charts mentioned above. The 20 gauge steel has a thickness of 0.0359 inches or 0.912 millimetres for standard steel.

2- How big is 22 gauge sheet metal?

As said before, to know the size of any gauge, you must mention the metal type. However, for standard steel, the 22 gauge is 0.0299 inches big.

3- Is 18 or 20 gauge thicker?

The 18 gauge will be thicker than the 20 gauge number as when they go downward, the gauge number increases and the thickness of the metal sheet decreases.

4- Which is thicker, 24 or 26-gauge metal?

The 24 gauge will be thicker than the 26 gauge number of any metal sheet. This rule is universal for all metals.

Conclusion

The metal gauge chart has undoubtedly solved the issue of metal thickness. Assigning the unit to metal sheet thickness without this measurement standard would have been a serious problem. However, life is easier with this chart.

I have discussed the metal gauge charts in detail in this article. Not only this, I have also mentioned the easy way to read and understand the chart so that the commoner can use the chart easily and benefit from it. My efforts will help you understand the gauge chart.