Undoubtedly, aluminum is one of the most used materials. Its softness, durability, and lightweight have made it the most wanted material in metalworking. However, this material is hard to cut and poses issues for beginners. So, this guide will show how to cut aluminum sheets and plates.

Whether you are a metal shop worker or a DIY enthusiast, this piece will be a must-read. Next time, you won’t have to worry about cutting aluminum sheets. We will discuss some cutting tools that make life easier. So, let’s get started!

Tools Required

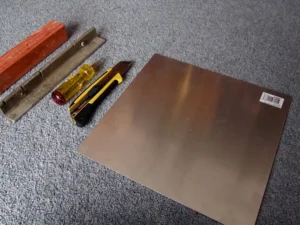

As I said, cutting aluminum sheets and plates requires some tools. Small, inexpensive tools will do the job if the aluminum sheets are thin. However, for thicker plates, you’ll need professional tools. Here is the list of the required tools:

- Tin Snips

- Utility Knife

- Circular Saw

- Jigsaw and Hacksaw

- CNC Milling Machine

- CNC Laser Cut Machine

- Table Saw and Band Saw

- Plasma Cutter & CNC Router

- CNC Waterjet Cutting Machine

Some of those tools are suitable for hobbyists and DIY geeks. However, many of those are useful at the professional level. Large metal fabricators use them to cut aluminum materials.

How to Cut Thin Aluminum Sheets and Plates?

It is noteworthy that aluminum sheet suppliers offer sheets with varying thicknesses. If you are dealing with a thin aluminum sheet below or up to 0.125 inches thick, you can cut it with a knife or tin snips. Usually, DIY enthusiasts use these tools to cut. Keep in mind that these tools are very easy to operate.

To cut the sheet, you just have to mark the cutting line. Once you’ve done this, place it on a stable surface. Before cutting, ensure the sheet does not move from its place. You can then start cutting with a tin snip—it’s more like cutting with a scissor.

Similarly, the utility knife is also handy for cutting thin aluminum material. However, these tools won’t work if you have a thicker sheet or plate. Notably, the sheet must be fully stable before you start cutting. If it is unstable, the sheet might bend, affecting the cutting precision.

Quick Highlight: Metal shears or tin snips cut aluminum sheets very cleanly. This tool works perfectly for all sizes, smaller or larger. Moreover, it can go into narrow sides and easily cut from any direction and position. This is due to its lightweight and better user-friendliness.

How to Cut Thick Aluminum Sheets and Plates?

If you work with thicker plates, you’ll require professional tools. Some of those tools are costly, and you’ll need a handsome budget to get them. However, some are relatively cost-effective and can be cut. Let’s dive in and discuss those different cutting tools and their working.

1- Circular Saw

This tool consists of a rotating blade that cuts aluminum sheets and plates. Most of the circular saws are powered by external sources through cords. The carbide circular blade of this tool is very sharp and has teeth. However, it effectively cuts the workpiece in one direction at a time.

Cutting aluminum sheets and plates through a circular saw is straightforward. First, mark the position from where you want to cut. Then, place the material under the rotatory blade. Switch the tool, and it will start cutting the aluminum material. Don’t force the tool; let it cut slowly and smoothly.

2- Jigsaw

This tool is more user-friendly as it gives the user control during cutting. It is usually handheld so the user can change its direction during cutting. Therefore, it allows you to cut the sheets and plates into intricate and complex shapes.

A jigsaw consists of a fine-toothed blade. The workpiece is placed or clamped on the worktable. The tools then start to cut the material according to the users. What makes this tool unique from others is its handheld feature. The user keeps it in hand while cutting. So, the chances of mistakes and wrong cutting are very low.

Moreover, the user can cut the sheet in one go. These tools also allow you to achieve different complex shapes. Keep in mind that different blade sizes are available for this tool. You should choose the blade size that is suitable for the specific size of your sheet or plate.

3- Hacksaw

The hacksaw is more like a jigsaw but is slightly under par compared to its counterpart. The reason is that it can only cut smaller aluminum sheets and plates. Fabricators use this tool to cut pipes and other aluminum materials. It does not work when cutting a thicker aluminum sheet or plate is needed.

It consists of three parts: frame, blade, and handle. You mount or install a blade on the frame, and the tool is ready to cut. Different blades are available on the market and are suitable for hacksaws. A blade with 18-32 teeth per inch (TPI) is recommended for aluminum cutting.

You should choose a blade with a higher TPI to achieve high cleanliness, smoothness, and finish. More teeth on the blades make them sharper, so they will cut aluminum sheets and plates quite easily. The only drawback of this tool is that it does not work when cutting the thicker aluminum sheets and plates.

4- Table Saw and Band Saw

Both table and band saw tools are exceptional for cutting aluminum sheets and plates. A table saw is a stationary tool and is easier to operate. It consists of a circular blade that cuts the material. The blade can be moved at different heights and angles.

This ensures the user cuts the aluminum sheets and plates at the desired angle. On the other hand, a band saw allows you to cut the material in curved shapes and intricate designs. Unlike table saws, the band saw consists of a continuous loop blade. This loop blade moves and cuts the workpiece efficiently.

You might be confused about deciding between these two cutting tools. The Bandsaw is superior because it offers a quick turnaround and can cut the thickest aluminum sheets and plates. However, the table saw is simple and easy to use.

Quick Tip: I recommend choosing a table saw if you are working with thin material. However, the band saw is a wise option for thicker material at a professional level. You’ll be able to cut the material quickly and precisely.

5- CNC Milling Machine

This machine is utilized at a professional level. The bigger manufacturers with big budgets use such machines to cut aluminum material quickly. As the name shows, these machines are based on CNC (Computerized Numerical Control). It means that their workings are controlled by computerized programs or software.

The workpiece (aluminum sheet or plate) is placed and clamped on the worktable. This machine consists of rotatory cutting tools. When the operator starts the process, the cutting tools cut the material as per computerized instructions.

What makes these cutting tools popular is their precision and accuracy. They are controlled by computerized instruction, and the rate of getting precise and accurate cutting is up to 99.9%. However, the price of these tools is very high, which is a drawback.

6- CNC Laser Cut Machine

This cutting machine is similar to the CNC mentioned above in the milling machine. However, it consists of a laser source instead of a cutting tool. This machine also offers exceptional precision as it is CNC-based. It means that it is controlled by computerized software.

Material is placed on the work table. The machine is programmed with instructions and then enters the working phase. The laser head moves and emits light on the part where a cut is needed. The laser light melts the aluminum and creates a cut easily.

Using a laser instead of a cutting tool differentiates it from a CNC milling machine. This process through this machine is very straightforward and requires minimal human labor. However, this machine is very expensive, like a CNC milling machine.

Point to Remember: You won’t see it in every metalworking shop. Instead, established manufacturers use them to meet their client’s deadlines. These machines can cut the thickest aluminum sheets and plates in seconds with 100% precision.

7- Plasma Cutter and CNC Router

Both plasma cutters and CNC routers offer very good precision. However, their working methods and efficiency differ. First of all, let’s discuss the plasma cutter tool. It uses electrically conductive gas to cut the material. In simple words, it utilizes hot plasma to cut the aluminum sheets.

Plasma cutters offer better-cutting quality when it comes to cutting thicker material. You won’t have to compromise on the quality of cuts. Conversely, the CNC router is more geared towards precision and accuracy. This CNC-based machine offers a quick turnaround with no errors or mistakes.

It is hard to decide between these tools. Both serve their purpose well. A CNC router is considered more reliable and quick. It can cut material of any size and shape in a moment. However, its cost is very high, which could be a hurdle for many people. Remember that the CNC router is worth the higher price for established fabricators.

8- CNC Waterjet Cutting Machine

This cutting machine is also very accurate. However, it is unique in its work. Instead of using blades, plasma, lasers, etc, it uses a hot stream of water. This hot stream of water is pushed with a very high pressure of more than 60000 psi. Such high pressure of hot water cuts the aluminum material.

As the name suggests, this tool is also controlled by computerized software. The water stream flows through the material according to the computer’s instructions. This machine offers the same high precision and accuracy every time. The CNC waterjet machine is also very versatile.

It cuts aluminum sheets and also works on other materials, including stone, wood, and glass. This machine is mostly used in industrial settings. It comes in handy when fabricating material in bigger quantities. Its cost of purchasing and installation is very high. Not only is it costly, but the maintenance of this machine is also complex and expensive.

Tips for Cutting Aluminum Sheets and Plates

There is no doubt that aluminum has excellent properties and benefits. However, its cutting is slightly more complex, especially if you are a newbie. Let’s discuss some of the precautions and tips that will help you when cutting aluminum sheets and plates:

- Aluminum is soft and can bend during cutting. Therefore, you must ensure it does not move or slip when you put a cutting blade on it.

- Don’t start cutting the sheet or plates if they are not on the stable surface. Before starting, keep the material in an equally stable place and then start to cut.

- If the aluminum sheet is thicker, I suggest you apply oil on the cutting line. It will reduce friction and offer smooth cutting.

- During cutting, you should always wear safety goggles and gloves. They will safeguard you from any unexpected event.

- Last but not least, you should never force the cutting tool. Instead, let it work at its speed. You will end up damaging the tools if you use them harshly.

What is the Best Tool to Cut Aluminum Plates?

It depends on your needs and the thickness of the aluminum material. If you aim to cut a thin aluminum sheet, using a tin snip would be the best option. On the other hand, if you are operating with thicker aluminum plates, a Band saw or CNC tools would be the optimal choice.

Different tools are available to cut aluminum plates. However, they are all different in terms of their precision and effectiveness. If you aim to achieve 100% precision, use CNC cutting tools. You’ll be able to cut the aluminum plates professionally with excellent accuracy.

However, if you are a DIY fanatic, I won’t suggest using expensive tools. Instead, a tin snip, jigsaw, or hacksaw would be the best options. Your level of professionalism also matters when choosing specific cutting tools.

Established businesses should choose expensive tools for better productivity. Such tools ideally give a quick turnaround. So, ask yourself before making the decision. Every aluminum plate-cutting tool is excellent. However, it can become a headache if you don’t choose it according to your needs.

Frequently Asked Questions

What tool to cut an aluminum sheet?

Different tools are available for cutting aluminum sheets. Which tools you should use depends on your needs and the thickness of the sheet. The tin snip tool is a good option for thin sheets. However, more professional tools are needed for thicker sheets.

Can you cut aluminum by hand?

Yes, cutting thin aluminum sheets by hand using a utility knife or tin snips is possible. However, thicker aluminum plates cannot be cut by hand. They require professional cutting tools with sharp blades.

Is aluminum difficult to cut?

Yes, aluminum is difficult to cut for many reasons. It is soft and bent during the cutting process and does not remain stable during cutting. So, it requires special skills and tools for its cutting.

What kind of saw to cut aluminum?

Different types of saws are available, such as circular saws, jigsaws, hacksaws, table saws, and band saws. You can use any of them depending on your needs. However, I suggest you use a jigsaw, as it gives better controls during cutting.

Conclusion

Aluminum is one of the most versatile materials. However, cutting it is more challenging than one may think. It requires tools and techniques to get the job done. Small tools such as utility knives or tin snips will be sufficient for DIY.

However, for professionals, the higher-priced tools are a must. These tools are specialized and cut the sheets and plates effectively. Before you start cutting, make sure to understand the tools. Choose only those cutting tools that are specialized for your type of cutting