Aluminum is one of the most used elements in different industries. From aerospace to automobile and food packaging, its presence is dominating everywhere. The aluminum metal stands out due to its non-corrosive and non-toxic nature. Aluminum’s applications are diverse. It was first known in 1825. But, it has silently served humans in different forms for centuries. In this guide, we will discuss the advantages and properties of aluminum metals. So, let’s get started!

Overview of Aluminum

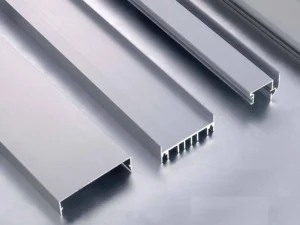

Aluminum is a silvery white-colored element that makes up 8% of the earth’s crust. It offers easy fabrication with excellent strength. It is extensively deployed in different industries because it is resistant to corrosion.

Interestingly, aluminum has been used since the Roman Empire. However, it was not known at that time. People used to use it unknowingly in the form of alum. However, in 1807, Humphry Davy indicated its presence.

Humphry Davy tried to extract it from alum through an electrolysis process. Unfortunately, he failed in the process. In 1825, Danish physicist and chemist Hans Christian Ørsted isolated aluminum successfully. He did that through the reduction of aluminum chloride.

Since then, scientists have started experimenting with aluminum. Today, it is the most used element. It offers multiple manufacturer-friendly properties, one of which is its corrosion resistance. In the section below, we will see the properties and advantages of aluminum metal.

Advantages & Properties of Aluminum Metal

As I said, aluminum is commonly used due to its properties. Those characteristics make it suitable for different purposes. Let’s dive deeper and explore aluminum’s advantages and properties.

1- Resistance to Corrosion

Corrosion resistance is the top advantage of aluminum. When aluminum material is exposed to moisture or oxygen, it forms a layer of oxide. This layer of oxide protects the material from rust and corrosion. Even in the worst conditions, the aluminum exhibits corrosion resistance.

Due to its rust resistance, it is used in different industries. Manufacturers enhance corrosion resistance by applying a thin coat of paint. This coating makes aluminum worthwhile in salty water (seawater). Such property makes it suitable for outdoor usage as well.

Not only is aluminum resistant to corrosion, but it is also super durable. Products made with this material remain in good shape for years to come. Many manufacturers use aluminum to make windows due to its rust resistance and strength.

2- Light Weight & Ductility

There are many industries where reduction of weight is crucial. Those industries include aerospace and automobiles. The manufacturers aim to enhance the quality without adding additional weight. In such cases, aluminum is handy.

The reason is that it is super lightweight. The pure form of aluminum weighs 2.7 g/cm3, lighter than steel (one-third of the total steel weight). Such lightweight aluminum makes it ideal for making airplane parts.

Similarly, aluminum’s ductility is well-known. The manufacturer shapes it into many different shapes. The aluminum bends but does not break even when a strong force is applied. Due to its excellent ductility, aluminum coils, sheets, etc., are made.

3- Non-Toxic & Impermeable

Many food cans and boxes consist of aluminum. Thanks to its excellent, non-toxic nature. It does not react with acidic or alkaline substances. Its presence in the soil does not affect its fertility. Not only is it non-toxic, it is impermeable as well.

Aluminum does not allow gasses or liquids to pass through it. When used to make a box, it ensures nothing escapes from the box. That’s why it is widely used in preserving food items. Such properties help manufacturers use it to make food packaging.

4- Recyclability & Strength

Aluminum offers an efficient recyclability rate of 100%. It shows that its maximum portion can be recycled. What makes it stand out is its stability during recycling. This process of recycling also needs less energy and is eco-friendly too.

Do I need to emphasize its strength? I don’t think so. It has a high strength-to-weight ratio. Even when it goes under force, it does not break. Under high pressure, it changes shape into coils, sheets, and so on. This shows its strength and durability in many conditions. Due to the strength of the aluminum, it is used in the construction work.

Point to Remember: Aluminum has a tensile strength of 90MPa. It is capable of resisting harsh environments. Even under harsh forces, it deforms but does not break into pieces easily.

5- Sound and Impact Absorption

The aluminum’s high ductility absorbs sounds, energy, and shocks. When it strikes with anything, it does not break. Instead, it absorbs the impact. It remains unaffected by high collisions. Usually, people also use aluminum in the building. Thanks to noise-reducing properties.

You might think of it as the solution to noise cancellation in the home. It is not! Its usage is to dampen the noise. You’ll still require a noise cancellation system if your home is near the road. It only reduces noise to a smaller extent. It won’t absorb the sound to 100% level.

6- Strength at Low Temperatures

Different materials when undergoing a low-temperature break. If they don’t, they crack and get brittle. But this is not the case with aluminum. It remains exceptionally stable even under low temperatures without posing any issues.

This property makes aluminum useful for different products that face temperature changes. Manufacturers use it to make parts for refrigerators and airplanes. These parts face the temperature variation. Aluminum remains stable in all conditions.

7- Non-sparking or Ignition

Aluminum has a low friction coefficient. It does not spark or ignite when it touches non-ferrous metals. That’s why people use it in high-risk work situations. For example, aluminum can be used as a filler.

The non-sparking nature extends the usability of this material. Industries that use flammable materials rely on aluminum-made equipment and tools. These tools do not pose any hazards while being used, so this significantly reduces the chances of hazards and risks.

8- Ease of Fabrications, & Reflectivity

Aluminum goes through casting, welding, machining, or forming quickly. It indicates its excellent machinability. As I said, it does not become brittle even if high pressure is applied. This makes the fabrication of aluminum very easy and cost-effective. It is also one of the most used materials in the industry.

Some products require reflectivity. These include lighting fixtures, solar panels, and thermal insulating materials. Aluminum is used in all such products and offers reflectivity characteristics. The good thing is that using aluminum for reflectivity is not expensive.

9- Non-Magnetics & Anodizing

Aluminum is undoubtedly strong. However, some industries require even more strength. For this purpose, manufacturers use the anodizing process in aluminum. In this method, an addition of oxide is applied to the aluminum. This gives the aluminum more strength, durability, and rust protection. The aluminum itself acts as an anode in this process.

The non-magnetic behavior of aluminum is also well known. Due to this property, aluminum is used to make many computer components. It is not attracted to the magnets. Not to forget, the aluminum also has an excellent surface finish. The manufacturers don’t make additional efforts to achieve an aluminum surface finish.

Point to Remember: Anodizing achieves high surface hardness and rust protection. It also perfectly makes aluminum shiny. Many industries use this metal more to enhance the physical outlook of products.

10- Thermal and Electrical Conductivity

Many electricity transmission lines use aluminum wires. Thanks to the high electrical conductivity of this material. As I said earlier, aluminum is very malleable. Thus, it becomes straightforward for fabricators to make wires from aluminum.

Another valuable property of this material is thermal conductivity. Aluminum is used in heat transmission electronics, such as heat exchangers and refrigerating systems.

Helpful Fact: Many people compare copper and aluminum regarding wires and electrical conductivity. Copper offers 50% better electrical conductivity than aluminum. This is why manufacturers prioritize copper for making wires, etc.

Applications of Aluminum

While discussing the advantages, I mentioned the usage of aluminum in different industries. But to clarify things, let’s discuss some top applications of aluminum. It will help you understand the nature of this material and its importance.

- Automobiles: Aluminum is commonly used in the automobile industry. This material is lightweight, so it is a handful to make components of cars, trucks, and trains. Many manufacturers use it to make vehicle bodies and frames.

- HVAC Systems: Aluminum is used extensively in HVAC systems. The reason is that it makes the components corrosion-resistant. So, the parts remain in good shape for the years to come.

- Packaging and Food Cans: It is widely used in packaging, especially for food and drink cans. All thanks to its non-toxic nature. No matter how long the food remains in aluminum cans, it does get spoiled.

- Electrical Transmission: As I mentioned earlier, aluminum has high electrical conductivity. Different wires are made of this material and are used to transmit electricity. It is also helpful in making the frames of solar panels.

- Construction Industry: It is used in construction work. Thanks to its high tensile strength. It has remained in good condition for years. Plus, the rust resistance further supports its usability.

- Electrical Appliances: In the section above, I mentioned that aluminum is non-magnetic. The force of attraction of magnetic forces has no impact on it. Therefore, it is widely used in making different types of computer electronics.

Many industries use aluminum due to its variety of properties. However, two main features make it so popular: its strength and rust resistance. Their usability is dominant in our daily lives. It won’t be wrong to say that aluminum makes modern life possible.

Limitations of Aluminum

Understanding the pros and cons of aluminum is important. In the section above, I mentioned the benefits of aluminum. However, to make a buying decision, it is vital to understand the cons as well. These will help you understand its strengths and weaknesses. In the section below, I will mention aluminum’s limitations and cons.

- No doubt aluminum is strong. However, it is easier than other elements. Steel is more rigid and is used in metalwork more often than aluminum. For heavy-duty work, aluminum is less common than steel.

- It has high thermal conductivity. This poses a severe challenge during the welding process. On aluminum, the weld becomes solid very quickly, making the welding hard. On the other hand, steel offers better and easier welding. That is why we do not use aluminum, where we need to weld two parts together.

- Aluminum has a higher coefficient of thermal expansion and contraction. When it goes under a high temperature, it expands. Similarly, it contracts under cold conditions. This makes it unfavorable for many activities.

- It is more expensive than steel. The manufacturer hesitates to use it for fabrication. Steel is preferred over aluminum for metalwork. This is due to the cost-effectiveness and ease of welding steel.

Frequently Asked Questions

What Is the Density of Aluminium?

The density of aluminum is approximately 2.70 grams per cubic centimeter (g/cm³). Such lower density makes aluminum one of the lightweight elements.

What Are the Physical Properties of Aluminium?

Physical properties related to shape and appearance are called physical properties. Aluminum’s physical properties include lightweight, ductility, malleability, corrosion resistance, and reflectivity.

What Are the Chemical Properties of Aluminium?

Properties related to aluminum’s composition are known as chemical properties. The chemical properties of aluminum include its reaction with oxygen to form oxide.

Is Aluminium Durable?

Aluminum is durable in many uses. This is because it resists corrosion and has a high strength-to-weight ratio. But, its durability can vary. It highly depends on the alloy mixture and the environment.

Conclusion

Aluminum is undoubtedly very versatile. Every industry depends on this material, and it serves human beings in many ways. From construction to automobiles, it is dominating the world in every aspect. However, it has some limitations that don’t affect its usability.

In this article, I have explained the advantages of aluminum metal. You’ll also learn the science behind its extensive usability. At HXSCO, we serve as the aluminum supplier. Contact us for aluminum sheets, wires, coils, and other aluminum-made products.