Understanding Stainless Steel Wire

In the intricate tapestry of industrial materials, Stainless Steel Wire stands as a stalwart thread, weaving its strength and versatility across various applications. Let’s delve into the essence of Stainless Steel Wire, exploring its composition and the key properties that render it the preferred choice in the realm of materials.

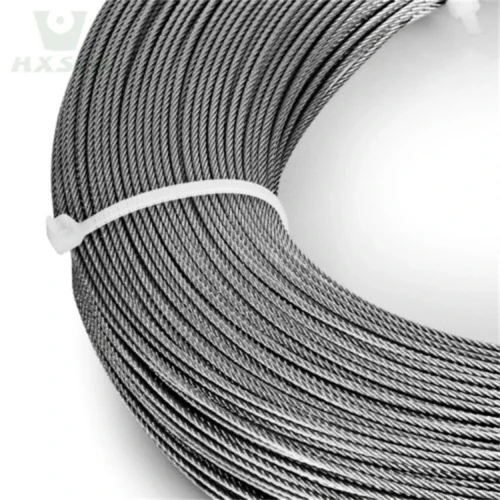

Defining Stainless Steel Wire

At its core, Stainless Steel Wire is a resilient and malleable alloy crafted from a fusion of iron, chromium, nickel, and other alloying elements. This amalgamation of metals imparts remarkable strength, corrosion resistance, and ductility to the wire, making it a cornerstone in industries ranging from construction to manufacturing.

The meticulous composition of Stainless Steel Wire distinguishes it from conventional steel counterparts. The inclusion of chromium, typically in the range of 10-20%, forms a protective chromium oxide layer on the surface of the wire. This layer is the unsung hero, providing unparalleled resistance to corrosion, rust, and staining, even in the face of harsh environmental conditions.

Key Properties Making it the Preferred Choice

Corrosion Resistance:

The Achilles’ heel of many materials is their vulnerability to corrosion. Stainless Steel Wire, however, emerges as a champion in corrosive environments. The chromium oxide layer acts as an impermeable shield, thwarting the advances of rust and corrosion, ensuring longevity and durability in applications where other materials may falter.

Strength and Ductility:

Stainless Steel Wire boasts a commendable tensile strength, making it adept at withstanding substantial mechanical loads. Simultaneously, its inherent ductility allows for intricate shaping without compromising structural integrity. This dynamic interplay of strength and flexibility positions Stainless Steel Wire as a versatile solution in diverse industrial settings.

Temperature Resilience:

In the crucible of extreme temperatures, Stainless Steel Wire remains unyielding. Its composition equips it to resist scaling and maintain structural stability, even when exposed to high temperatures. This resilience makes it a reliable choice for applications that demand steadfast performance in challenging thermal environments.

Aesthetic Appeal:

Beyond its mechanical prowess, Stainless Steel Wire adds an aesthetic dimension to applications. Its smooth, polished surface not only enhances visual appeal but also facilitates easy cleaning, making it suitable for applications where hygiene is paramount.

Low Maintenance:

Stainless Steel Wire requires minimal upkeep, thanks to its resistance to corrosion and staining. This low maintenance characteristic translates into cost savings over the long term, amplifying its appeal for budget-conscious industries.

Versatility in Applications:

The adaptability of Stainless Steel Wire spans across a myriad of industries. From reinforcing structures in construction to forming the backbone of intricate machinery, its versatility is a testament to its ability to meet diverse application needs.

In the intricate dance of industrial materials, Stainless Steel Wire emerges not merely as a component but as a strategic asset. Its composition, defined by resilience and adaptability, lays the foundation for a material that transcends the ordinary.

As Stainless Steel Suppliers, we recognize the profound impact that Stainless Steel Wire can have on the success of diverse projects. Our commitment to delivering quality materials stems from a deep understanding of the nuanced requirements of our clients. With Stainless Steel Wire at the heart of our offerings, we stand as your reliable partners in building a future fortified by strength, durability, and innovation.