Understanding 316 Stainless Steel Sheet

Stainless steel is a marvel of modern metallurgy, revered for its exceptional properties and versatile applications across various industries. Its ubiquity in everything from kitchen appliances to industrial machinery underscores its significance. In this section, Stainless Steel Suppliers HXSCO will delve into the fundamental aspects of stainless steel, introduce the 316 Stainless Steel Sheet, and unravel the benefits it brings to the table.

Stainless Steel: The Unyielding Alloy

Stainless steel is an alloy renowned for its remarkable resistance to corrosion, staining, and rust – qualities that set it apart from conventional steel. The secret behind this resilience lies in its composition, primarily composed of iron, chromium, and other alloying elements such as nickel and molybdenum. This amalgamation gives birth to a material that’s not only aesthetically pleasing but also extraordinarily durable.

Its versatility spans numerous industries, from architecture and construction to healthcare and food processing. The aerospace sector values stainless steel for its high-strength properties, while the medical field relies on its biocompatibility. Stainless steel is a common choice in building facades, kitchen appliances, cutlery, and even the towering structures that define our urban landscapes.

Introducing 316 Stainless Steel Sheet

Within the stainless steel family, the 316 Stainless Steel Sheet holds a prestigious position. Also known as marine-grade stainless steel, it is an austenitic stainless steel renowned for its exceptional resistance to both corrosion and pitting. This superior resistance is primarily attributed to its distinctive composition.

Comprising approximately 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, 316 Stainless Steel Sheet is well-suited for applications in aggressive environments. The presence of molybdenum reinforces its resistance to chlorides and other corrosive agents, making it particularly ideal for coastal or marine settings. This composition grants it the moniker of being the “workhorse” of the stainless steel family.

Advantages Of 316 Stainless Steel Sheet

Unmatched Corrosion Resistance

One of the primary advantages of 316 stainless steel sheet is their exceptional corrosion resistance. With its high chromium and nickel content, coupled with the addition of molybdenum, 316 stainless steel exhibits superior resistance to corrosion in aggressive environments, including chloride-rich and acidic conditions. This makes it an ideal choice for marine applications, chemical processing plants, and coastal structures.

Pitting and Crevice Corrosion Resistance

316 stainless steel sheet are particularly renowned for their resistance to pitting and crevice corrosion. Pitting corrosion occurs as localized corrosion attack on the metal’s surface, while crevice corrosion happens in tight crevices or gaps. Thanks to its unique composition, 316 stainless steel is highly resistant to both types of corrosion, ensuring longevity and structural integrity in challenging environments.

Excellent Strength and Durability

316 stainless steel sheet possess impressive strength and durability, making them suitable for structural applications. The alloy retains its mechanical properties even at elevated temperatures, providing excellent performance under demanding conditions. Whether it’s in high-pressure vessels, heat exchangers, or structural components, 316 stainless steel sheet offer the strength and reliability required for critical applications.

High Temperature Resistance

Another notable advantage of 316 stainless steel sheet is their ability to withstand high temperatures without significant degradation. This makes them ideal for applications in industries such as automotive, aerospace, and power generation. The alloy’s heat resistance ensures reliable performance and dimensional stability, even in extreme temperature environments.

Versatility and Adaptability

316 stainless steel sheet are highly versatile and can be easily tailored to suit specific requirements. They can be cold worked, machined, and fabricated using various techniques, allowing for customization and adaptation to different applications. Stainless steel suppliers like us can provide 316 stainless steel sheet in various thicknesses, widths, and lengths, ensuring the right fit for your specific project needs.

Aesthetic Appeal and Hygienic Properties

In addition to its functional advantages, 316 stainless steel sheet also offer aesthetic appeal. With their smooth and polished surface finish, they are commonly used in architectural and decorative applications, such as interior design elements, furniture, and signage. Furthermore, 316 stainless steel sheet are easy to clean and maintain, making them suitable for industries with strict hygiene requirements, such as food processing, pharmaceuticals, and healthcare.

Longevity and Cost Efficiency

The exceptional corrosion resistance and durability of 316 stainless steel sheet contribute to their long service life and reduced maintenance costs. By choosing 316 stainless steel, you can minimize the need for frequent replacements and repairs, resulting in cost savings over the long term. Its ability to withstand harsh environments ensures reliable performance and longevity, making it a cost-effective solution for many applications.

316 stainless steel sheet offer a wide range of advantages, including exceptional corrosion resistance, high strength, heat resistance, versatility, and aesthetic appeal. As experienced stainless steel suppliers, we understand the importance of providing high-quality 316 stainless steel sheet that meet your specific requirements. Contact us for personalized assistance and reliable solutions for your stainless steel needs.

Applications Of 316 Stainless Steel Sheet

Construction: Building with Confidence

In the world of construction, 316 Stainless Steel Sheet finds itself at the forefront of architectural innovation. Its corrosion resistance and durability are instrumental in ensuring that structures endure the test of time. Here’s how it contributes:

Architectural Facades: 316 Stainless Steel Sheet is a favorite choice for creating stunning building facades. Its sleek and polished appearance enhances the aesthetic appeal of modern skyscrapers and contemporary architectural designs.

Structural Elements: When structural integrity is non-negotiable, 316 Stainless Steel Sheet steps in. Its strength and corrosion resistance make it suitable for beams, columns, and other critical structural components, ensuring the longevity of buildings.

Coastal and Marine Structures: Coastal environments subject structures to relentless assaults from saltwater and corrosive elements. Stainless Steel suppliers often recommend 316 Stainless Steel Sheet for coastal construction, as it resists corrosion caused by seawater and saline air.

Manufacturing: Precision and Performance

Manufacturing industries demand materials that can withstand the rigors of production while maintaining precision and quality. 316 Stainless Steel Sheet is a trusted companion in these settings:

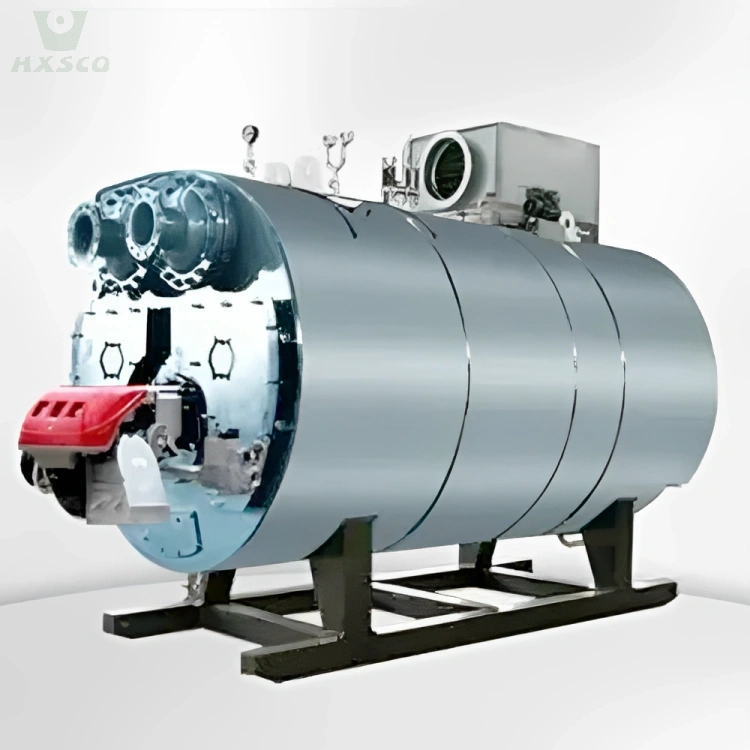

Machinery and Equipment: Manufacturing machinery often operates under harsh conditions, including exposure to chemicals and high temperatures. 316 Stainless Steel Sheet components remain reliable under these stresses, contributing to the durability of industrial equipment.

Chemical Processing: The chemical industry relies on stainless steel that can withstand corrosive chemicals. 316 Stainless Steel Sheet’s resistance to acids and chemicals makes it an ideal choice for vessels, tanks, and pipelines.

Pharmaceutical Equipment: In pharmaceutical manufacturing, hygiene and corrosion resistance are paramount. 316 Stainless Steel Sheet ensures that equipment maintains purity and integrity during the production of pharmaceuticals.

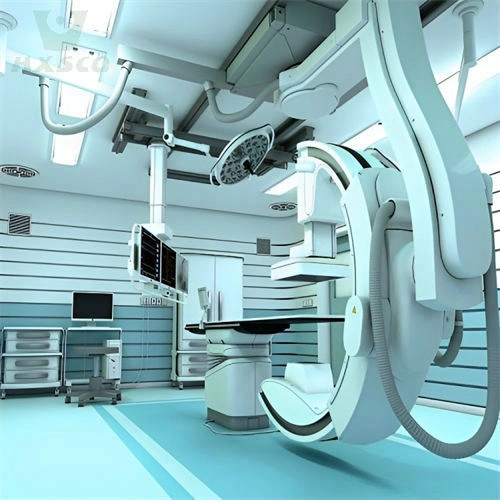

Healthcare: Purity and Hygiene

In the healthcare sector, maintaining strict hygiene standards is non-negotiable. 316 Stainless Steel Sheet plays a pivotal role in ensuring patient safety and product integrity:

Medical Devices: From surgical instruments to medical equipment, 316 Stainless Steel Sheet is chosen for its biocompatibility and ease of sterilization. It safeguards patients and medical professionals alike.

Pharmaceutical Manufacturing: In the pharmaceutical industry, maintaining a sterile environment is imperative. 316 Stainless Steel Sheet is used in cleanroom equipment and pharmaceutical processing equipment to meet these stringent requirements.

Dental and Orthopedic Implants: The biocompatibility and corrosion resistance of 316 Stainless Steel Sheet make it an ideal choice for dental and orthopedic implants, ensuring patient comfort and long-lasting performance.

Beyond these core industries, the applications of 316 Stainless Steel Sheet are as diverse as the imagination allows. Its presence can be found in kitchen appliances, transportation, oil and gas exploration, and even the brewing industry. Stainless Steel suppliers recognize the enduring demand for this material due to its unrivaled corrosion resistance and adaptability.

In conclusion, the 316 Stainless Steel Sheet is not merely a material; it is a symbol of reliability, durability, and performance. From towering skyscrapers to life-saving medical devices, it has found its place in an array of industries where excellence is the standard. Its role in construction, manufacturing, and healthcare underscores its adaptability and versatility. As industries evolve, the enduring significance of 316 Stainless Steel Sheet remains unwavering, ensuring that the world is built, crafted, and healed with utmost precision and care.

Technical Specifications Of 316 Stainless Steel Sheet

In the world of stainless steel, precision matters. The 316 Stainless Steel Sheet, often considered a close cousin to the well-known 304 Stainless Steel Sheet, comes with a range of technical specifications that determine its performance across various applications. In this section, Stainless Steel Suppliers HXSCO dive into the specifics of 316 Stainless Steel Sheet, shedding light on dimensions, thickness, tolerances, and their profound relevance in different industries.

Dimensions and Thickness

Dimensions: The dimensions of 316 Stainless Steel Sheet can vary to suit the specific needs of diverse applications. Standard sheet sizes often include widths of 1000 mm, 1219 mm, 1500 mm, and 2000 mm, with lengths ranging from 2000 mm to 6000 mm. However, custom dimensions can be fabricated to meet project requirements precisely.

Thickness: 316 Stainless Steel Sheet is available in a variety of thicknesses, typically ranging from 0.4 mm to over 100 mm. These varying thicknesses cater to a wide spectrum of applications, from delicate medical instruments requiring thin sheets to heavy-duty industrial machinery necessitating thicker panels.

Tolerances: Precision Matters

Tolerances are critical in the world of stainless steel. They refer to the permissible variations in dimensions, ensuring that each 316 Stainless Steel Sheet meets precise specifications. The relevance of tolerances extends far beyond the technical realm; it directly impacts the quality and performance of the final product.

In applications where precision is paramount, such as aerospace engineering and the manufacturing of critical medical components, tight tolerances are essential. Stainless Steel suppliers understand that even the smallest deviation can compromise the functionality and safety of a product. For example, in aerospace, where 316 Stainless Steel Sheet might be used for structural components, stringent tolerances ensure that aircraft maintain their structural integrity under extreme conditions.

Conversely, in less critical applications, such as architectural cladding, slightly broader tolerances may be acceptable. However, these tolerances still play a pivotal role in ensuring that panels align seamlessly during installation, contributing to the overall aesthetic and structural integrity of the building.

Relevance Across Industries

The specifications of 316 Stainless Steel Sheet are not one-size-fits-all; rather, they are meticulously tailored to suit the specific demands of each industry:

Construction: In the construction industry, precise dimensions and tolerances ensure that stainless steel panels align perfectly during installation, enhancing both structural integrity and visual appeal. Varied thickness options cater to different structural requirements, from lightweight cladding to load-bearing components.

Manufacturing: In manufacturing, where precision machinery is paramount, tight tolerances are essential to guarantee the seamless operation of equipment. Varied thicknesses accommodate diverse applications, from thin gauge sheets used in electronics to thick plates employed in heavy machinery.

Healthcare: In the healthcare sector, where medical devices must conform to strict regulations, precise tolerances are crucial to ensure the safety and efficacy of equipment. Custom dimensions and thicknesses are often required to meet the unique needs of each device.

Transportation: In the transportation industry, where weight and strength are key factors, the ability to select specific thicknesses of 316 Stainless Steel Sheet is vital. Whether it’s for lightweight automotive components or heavy-duty marine vessels, the material’s versatility shines through.

Oil and Gas: In the oil and gas sector, where corrosive environments are common, the corrosion resistance of 316 Stainless Steel Sheet is invaluable. Custom dimensions and thicknesses are adapted to suit the demands of offshore platforms, pipelines, and processing equipment.

In conclusion, the technical specifications of 316 Stainless Steel Sheet are a testament to the adaptability and precision demanded by various industries. From tight tolerances in aerospace to custom dimensions in healthcare, these specifications ensure that the material is not merely a commodity but a tailored solution for each application. Stainless Steel suppliers recognize the importance of these specifications in delivering the performance and reliability expected in the diverse world of stainless steel applications.

316 Stainless Steel Sheet Compared With Other Grades

In this saction, Stainless Steel Suppliers HXSCO will conduct a comparative analysis of 316 stainless steel sheet with other stainless steel grades. As trusted stainless steel suppliers, we aim to provide insights into the unique characteristics, advantages, and applications of 316 stainless steel sheet, highlighting their distinguishing features in comparison to other grades.

Corrosion Resistance

316 stainless steel sheet excel in terms of corrosion resistance. Compared to other stainless steel grades, such as 304 or 430, 316 stainless steel exhibits superior resistance to corrosive environments, including chloride-rich and acidic conditions. This makes it the preferred choice for applications in marine, chemical, and coastal environments where exposure to corrosive substances is significant.

Molybdenum Content

A key differentiating factor of 316 stainless steel is its higher molybdenum content. The presence of molybdenum enhances the alloy’s corrosion resistance properties, making it particularly effective against pitting and crevice corrosion. In contrast, other stainless steel grades may not offer the same level of protection against localized corrosion attacks.

Strength and Durability

316 stainless steel sheet offer excellent strength and durability, making them suitable for structural applications. Compared to austenitic grades like 304 stainless steel, 316 stainless steel exhibits higher tensile strength and improved resistance to stress corrosion cracking. This makes it a preferred choice for applications requiring robustness and longevity.

Heat Resistance

While 316 stainless steel demonstrates good heat resistance, it is important to note that other stainless steel grades, such as 310 or 321, offer even better performance in high-temperature environments. These grades contain higher levels of chromium and nickel, providing superior resistance to oxidation and scaling at elevated temperatures.

Magnetic Properties

Unlike some other stainless steel grades, such as 400 series (e.g., 430), 316 stainless steel is non-magnetic. This property is beneficial in applications where magnetic interference is undesirable, such as in sensitive electronic equipment or certain medical devices.

Price Considerations

In terms of pricing, 316 stainless steel sheet generally command a higher cost compared to some other stainless steel grades, such as 304 or 430. This is primarily due to the alloy’s increased corrosion resistance and the presence of molybdenum. However, the cost differential should be weighed against the specific requirements and performance needed for each application.

Applications

316 stainless steel sheet find widespread applications across various industries due to their unique combination of corrosion resistance, strength, and versatility. They are commonly used in marine environments, chemical processing plants, food and beverage processing, architectural and decorative applications, medical equipment, and power generation. Other stainless steel grades may be more suitable for specific applications based on their specific properties.

316 stainless steel sheet stand out among other stainless steel grades, particularly in terms of corrosion resistance, thanks to the inclusion of molybdenum. Their exceptional strength, durability, and versatility make them ideal for a wide range of applications. As experienced stainless steel suppliers, we offer high-quality 316 stainless steel sheet and can provide expert guidance to help you choose the most suitable stainless steel grade for your specific requirements. Contact us for reliable solutions tailored to your application needs.

Conclusion

In the dynamic landscape of stainless steel, precision, durability, and reliability are the pillars upon which the 316 Stainless Steel Sheet proudly stands. As you embark on your projects, whether in the realms of construction, manufacturing, healthcare, or any other industry, remember that the choice of materials can be the linchpin of success.

While the 304 Stainless Steel Sheet holds its own merit, the 316 Stainless Steel Sheet offers an additional layer of resilience, particularly in corrosive environments. Its ability to withstand the relentless forces of nature and the demanding requirements of diverse applications has made it a stalwart choice for those who seek excellence.

At Stainless Steel Suppliers, we understand that your projects are as unique as your vision. That’s why we offer not just a product but a tailored solution. Our commitment to precision, from dimensions and thickness to tolerances, ensures that each 316 Stainless Steel Sheet you receive is engineered to elevate your projects to new heights.

As you embark on your journey, be it the construction of architectural marvels, the precision of manufacturing, the sanctity of healthcare, or the challenges of transportation and energy, trust in the versatility of 316 Stainless Steel Sheet. It’s not merely a material; it’s a promise of performance, endurance, and quality.

In the world of stainless steel, where every detail counts, make your choice count as well. Choose 316 Stainless Steel Sheet, the material that speaks the language of excellence, and partner with Stainless Steel Suppliers to ensure that your projects stand the test of time and exceed expectations.

Elevate your projects with the enduring strength of 316 Stainless Steel Sheet, and let your vision become a reality. Contact Stainless Steel Suppliers today to discover how we can empower your endeavors with precision and reliability. Your success is our commitment.