HXSCO - Reliable Stainless Steel Supplier

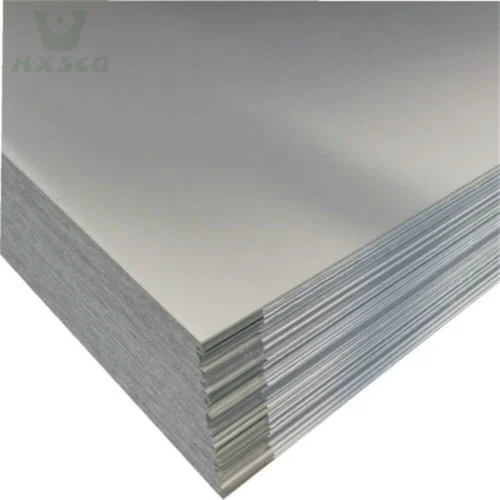

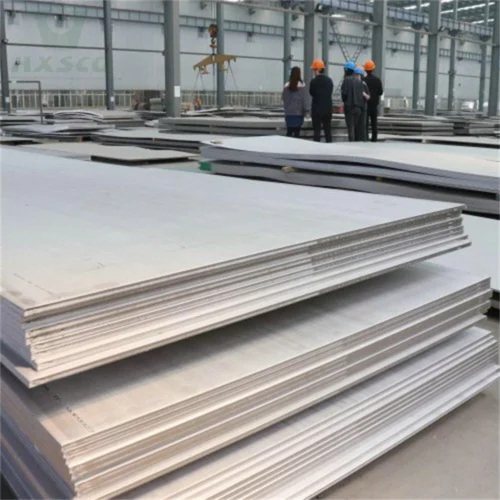

HXSCO is a stainless steel supplier and manufacturer in China. We supply high-quality stainless steel materials to customers worldwide. HXSCO is also a professional stainless steel distributor. We have more than 15 years of experience in the metal industry.

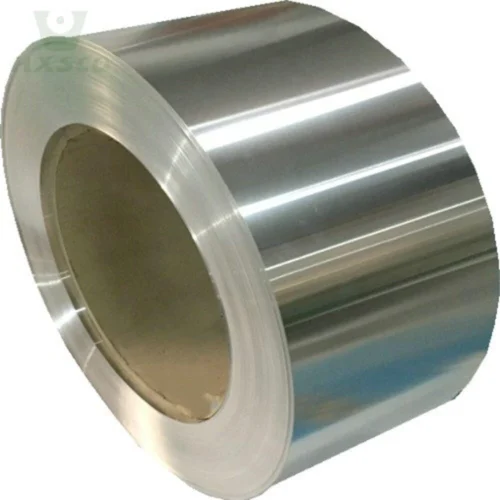

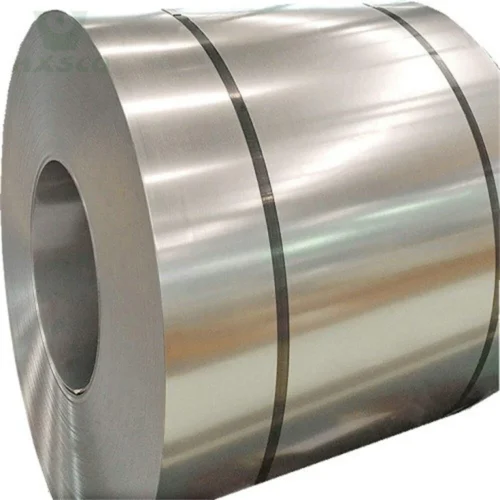

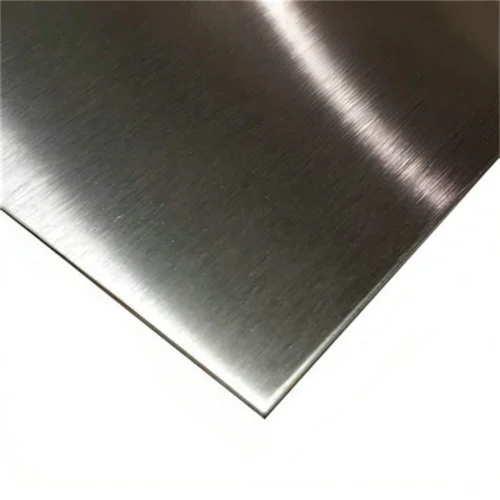

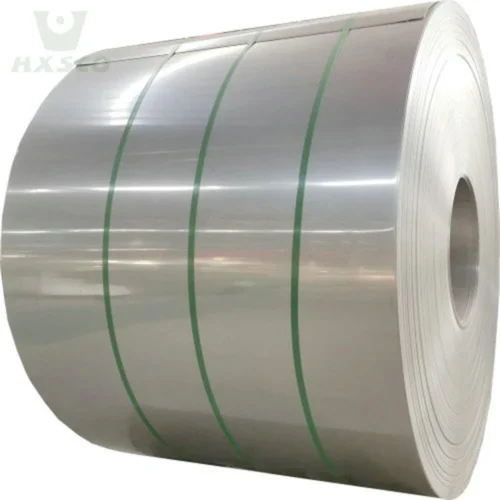

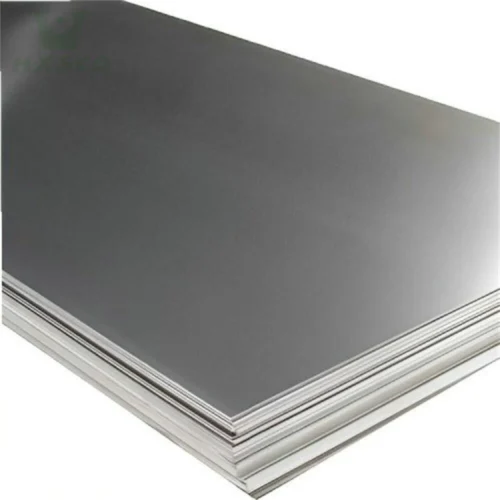

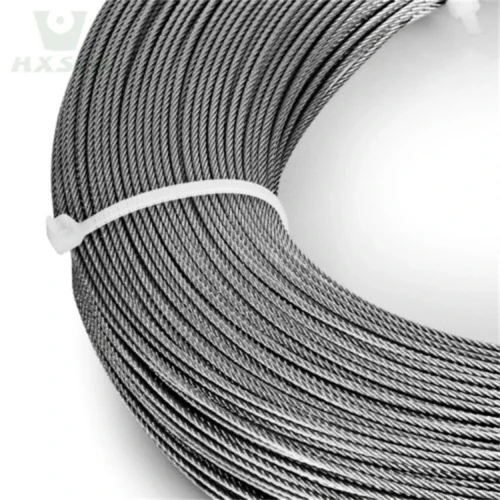

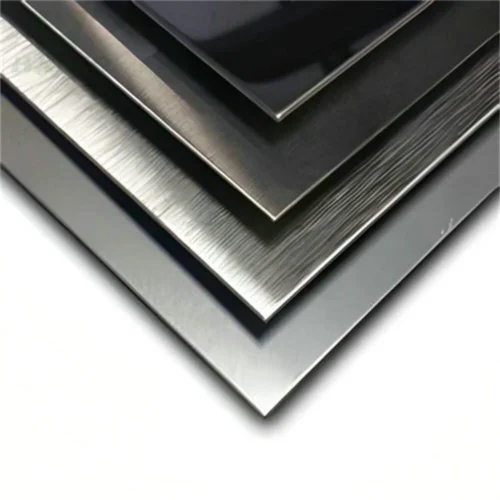

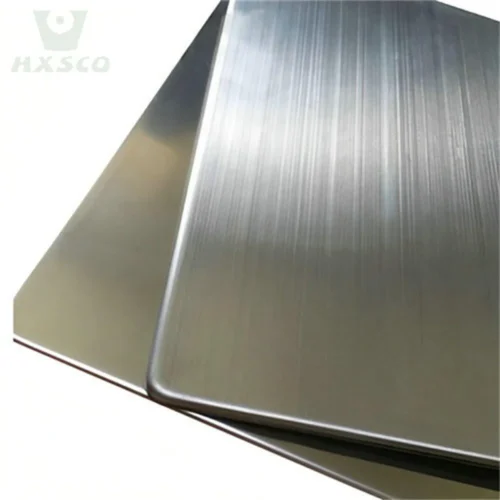

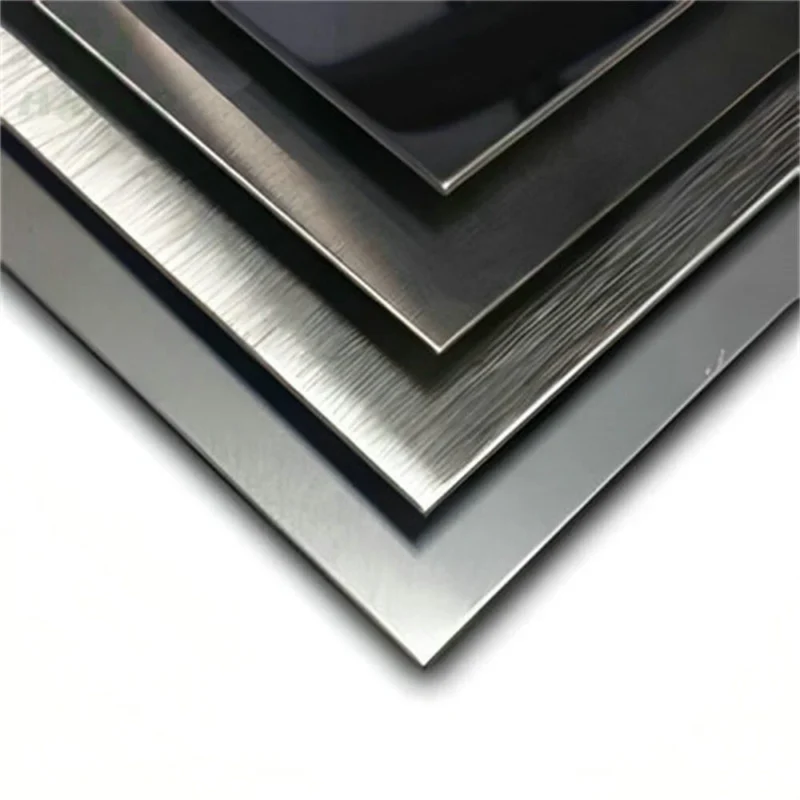

HXSCO has a wide range of stainless steel products. Our stainless steel metal is suitable for many uses. It ranges from food-grade stainless steel to highly corrosion-resistant stainless steel. Our stainless steel material has many advantages. These advantages are excellent corrosion resistance, high strength, and beautiful appearance. These characteristics make HXSCO's stainless steel supply a logical choice in many fields. Construction, home furnishing, medical equipment, and chemical equipment. These fields all have our stainless steel products.

HXSCO has won widespread praise from customers for its strict quality control. Customers also appreciate its professional services. Need to contact a stainless steel supplier? HXSCO SS manufacturer can provide satisfactory products and services.