Classification Of Stainless Steel Coil

430 Stainless Steel Coil

304 Stainless steel coil

321 Stainless steel coil

316 Stainless steel coil

According to its characteristics and uses, it can be divided into the following type

1. Ordinary stainless steel coil: mainly used for general purposes, such as making kitchen utensils, building materials, etc. Among them, the most common ones are 304 stainless steel coil and 316 stainless steel coil.

High temperature stainless steel coil: It has the characteristics of high temperature resistance, oxidation resistance and corrosion resistance, and is mainly used to make high temperature equipment and stoves. Among them, the most common is 310S stainless steel coil.

2. Corrosion-resistant stainless steel coil: It has good corrosion resistance and is mainly used to make chemical equipment and marine equipment. Among them, the most common is 316L stainless steel coil.

3. Super stainless steel coil: with high strength, high toughness, and good corrosion resistance, it is mainly used to make high-end equipment and appliances. Among them, the most common is 904L stainless steel coil.

4. Titanium-coated stainless steel coil: The stainless steel coil with titanium coating on the surface has excellent antifouling performance and corrosion resistance, and is mainly used for architectural decoration and electrical appliance manufacturing.

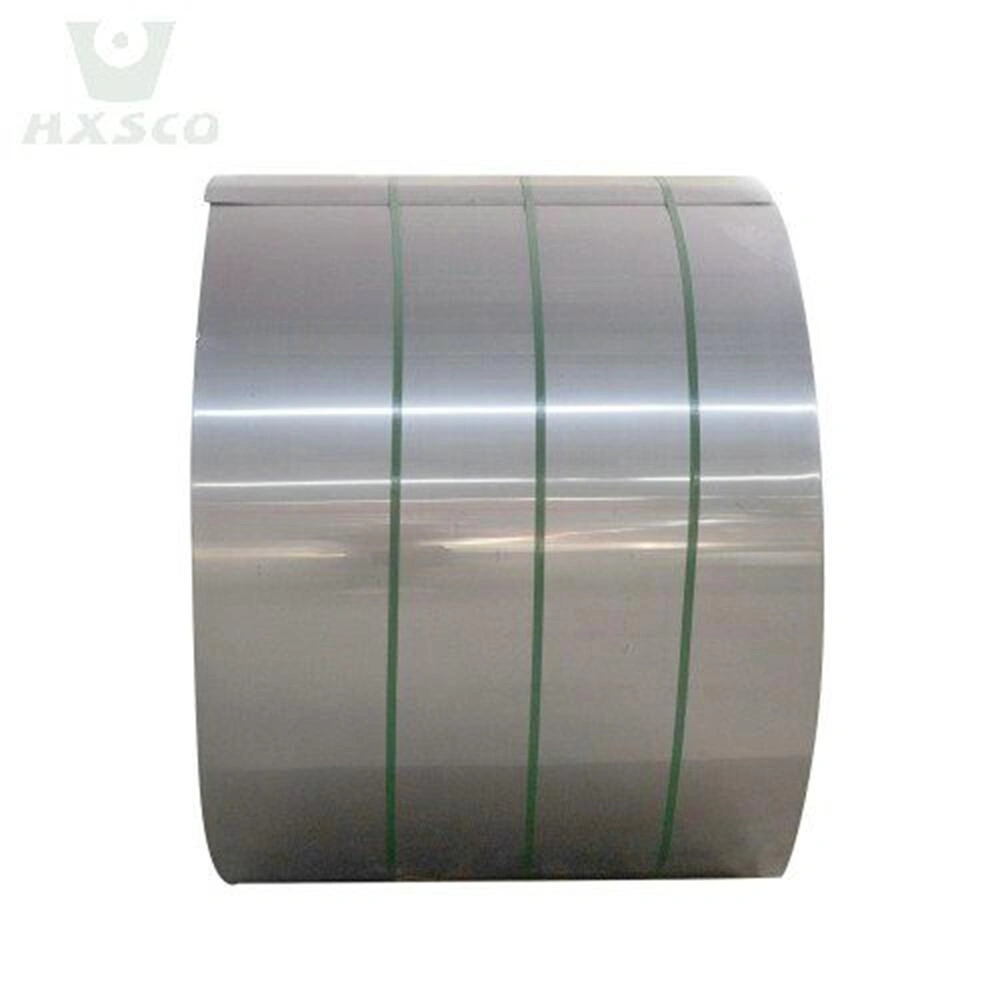

According to the material, it can be divided into stainless steel cold rolled coil and stainless steel hot rolled coil

Stainless steel cold-rolled coil has a smooth surface, high hardness, and good corrosion resistance. It is often used in the production of high-end products such as chemical equipment, medical equipment, and kitchen utensils. Stainless steel hot-rolled coils have a slightly rough surface and are often used to make building materials and auto parts.

According to the different widths of coils

Stainless steel coil can be divided into narrow coils and wide coils. Narrow rolls are usually less than 600mm wide, while wide rolls are more than 600mm wide.

According to the surface treatment process, it is divided into different types such as 2B, BA, NO.1, HL and so on.

Among them, 2B has poor surface finish and is suitable for occasions that do not require high surface requirements; BA has good surface finish and is suitable for making high-end home appliances and other products; NO.1 has a smooth and bright surface and is suitable for architectural decoration and other fields; Texture, suitable for elevator decoration and other occasions.

Application Of Stainless Steel Coil

Construction field

stainless steel coil can be made into building decoration materials such as walls, ceilings, stair handrails, doors and windows, and can also be used for indoor and outdoor decoration, kitchen equipment, etc.

Machinery manufacturing field

stainless steel coil can be used to manufacture machine parts, instruments, bearings, springs and other mechanical parts, and can also be used to manufacture parts of ships, automobiles, trains and other vehicles.

Chemical industry

Stainless steel coil can be used to manufacture chemical equipment, storage tanks, pipelines, etc. Its excellent corrosion resistance can ensure the stability and safety of the chemical reaction process.

Food processing field

stainless steel coil can be used to manufacture food processing equipment, cooking utensils, tableware, etc., because it will not react with chemical substances in food, so it can ensure food hygiene and safety.

With the continuous advancement of science and technology and the continuous improvement of people’s requirements for material performance, stainless steel suppliers HXSCO speculates that there will be some potential new applications for stainless steel coil:

Medical devices: Stainless steel coil have excellent corrosion resistance and biocompatibility, and can be used to manufacture various medical devices, such as surgical instruments, implants, cardiac pacemakers, etc.

Solar panels: Stainless steel coil have good thermal conductivity and are suitable for manufacturing brackets, frames and other components in solar panels.

Packaging materials: Stainless steel coil have good corrosion resistance and hygienic performance, and can be used to make packaging materials such as food and medicine.

Maintenance Suggestions Form Stainless Steel Suppliers

Stainless steel coil need regular maintenance during use to prolong the service life of stainless steel coil, improve their performance and aesthetics, improve product quality, reduce production costs, and ensure production safety. Here are some maintenance recommendations from stainless steel suppliers for you:

REGULAR CLEANING

he surface of stainless steel coil is susceptible to dirt and oxides, and regular cleaning can maintain its appearance and luster. Wipe with a mild detergent and a soft cloth to avoid scratching the surface.

REGULAR OILING

You can use stainless steel anti-rust oil or lubricating oil to coat the surface of stainless steel coil to prevent oxidation and corrosion. If there is damage or oxidation on the surface of the stainless steel coil, it will affect the quality of the manufactured product. Maintenance can reduce these negative effects and improve product quality.

AVOID COLLISIONS

When transporting and using stainless steel coil, avoid collisions with other hard objects to avoid damage to the surface.

AVOID HUMID ENVIRONMENT

Stainless steel coil should avoid being in a humid environment for a long time to avoid rust. If rust is found, it should be removed in time and coated with stainless steel anti-rust oil for protection.

REGULAR INSPECTION

Regularly check whether there are scratches, dents or other damage on the surface of the stainless steel coil, and repair or replace it in time. If there is a problem with the stainless steel coil in use, it needs to be repaired or replaced. Otherwise, production safety may be affected. Maintenance can detect and deal with problems in time to improve safety.

When performing maintenance on stainless steel coil, there are some common mistakes that can negatively affect stainless steel coil. Here are some common mistakes to avoid:

1. Use hard cleaning tools: Use hard cleaning tools, such as steel wool, sandpaper, etc. to clean the surface of stainless steel coil, which may easily cause scratches and damage on the surface, and should be cleaned with soft cloth or sponge. Use a soft sponge or cloth to avoid scratching the surface of the stainless steel coil.

2. Use chlorine or fluoride-containing cleaners: use of chlorine or fluoride-containing cleaners will cause corrosion to the surface of stainless steel coil, and neutral or low-alkaline cleaners should be used. Stainless steel coil can be cleaned with warm and soapy water, acetic acid, or a detergent such as sodium hydroxide.

3. Soaking in acidic or alkaline liquid for a long time: soaking in acidic or alkaline liquid for a long time, the surface of stainless steel coil is prone to corrosion and oxidation, so long-term immersion should be avoided as much as possible. Rinse the stainless steel coil with clean water and dry the surface with a clean towel to ensure no residue or water marks are left behind.

4. Ignoring cleaning: If there is dirt and oxides on the surface of the stainless steel coil, if it is not cleaned for a long time, the surface quality will decline, and it should be cleaned regularly. Stainless steel coil should be checked regularly to ensure they are functioning properly. If there is any problem, the stainless steel coil should be repaired or replaced in time.

5. Improper oiling: Stainless steel coil require oiling maintenance, but using incorrect lubricating oil or stainless steel anti-rust oil may cause oil stains and adverse effects on the surface. Specially designed rust inhibitors can be used to protect stainless steel coil, especially in wet or corrosive environments. The directions for use of the rust inhibitor should be followed.

Manufacturing Process From Stainless Steel Suppliers

Different stainless steel suppliers may have some differences in details, but the basic principles are similar. In the manufacturing process of stainless steel coil, it is very important to strictly control the manufacturing process, strictly implement each process step, and ensure the stability and reliability of the coil quality.

🔘Raw material preparation

Different qualities and types of stainless steel materials have a great influence on the quality of the coil. Select suitable stainless steel materials as raw materials, and process and treat them in order to make plates that meet the requirements.

🔘🟡Hot rolling

Put the heated stainless steel sheet into a rolling mill for hot rolling to deform it into a coil of required thickness and width. The difference in temperature and speed during hot rolling will affect the deformation, grain structure and mechanical properties of the coil.

🔘🟡🟠Pickling

The hot-rolled coils are pickled to remove oxides, rust and other impurities on the surface.

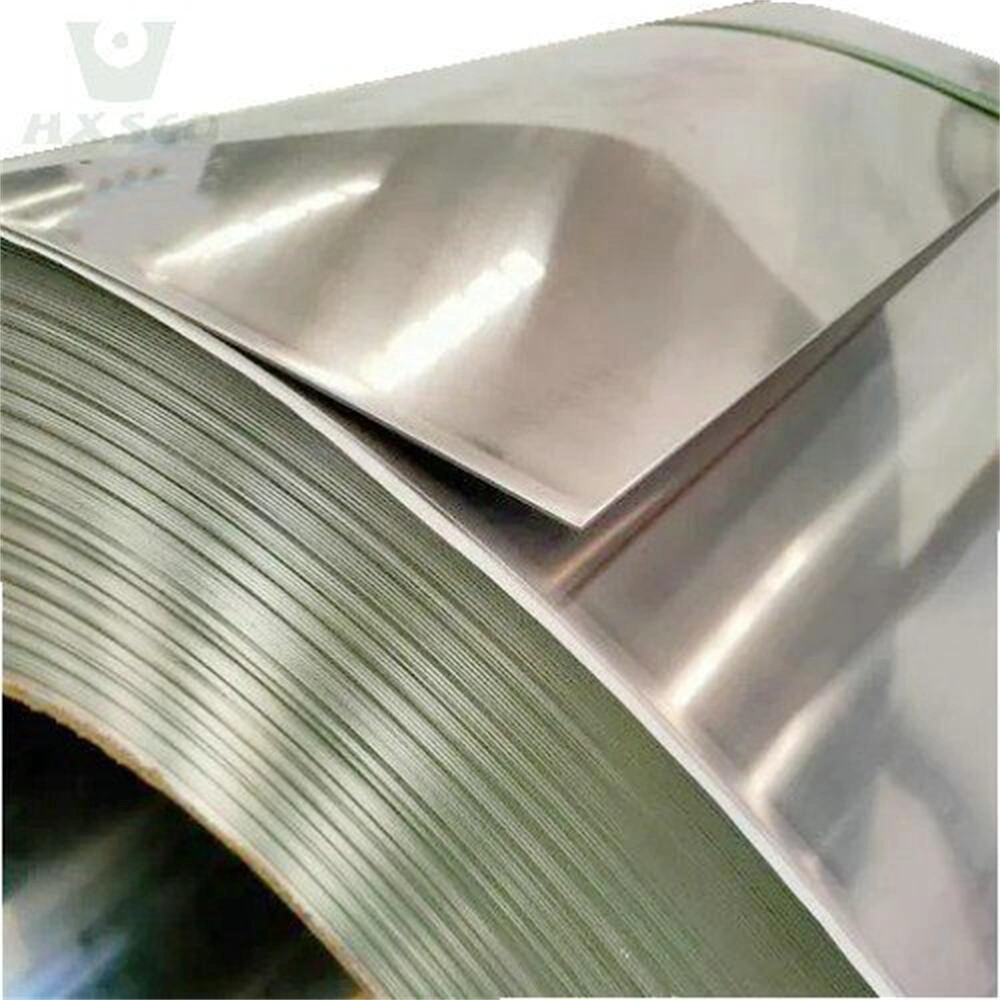

Cold rolling

Stainless steel suppliers put the pickled coil into a cold rolling mill for cold rolling to make the surface smoother, and also to further adjust its thickness and width. Whether the process control of pickling and cold rolling can be reasonable directly affects the surface finish, thickness accuracy and internal structure of the coil.

🔘🟡🟠Annealing

The cold-rolled coil is annealed to eliminate internal stress and structural inhomogeneity, so that it has better workability and strength. The difference in annealing temperature and time will affect the grain size, hardness, processability and strength of the coil.

🔘🟡🟠Galvanizing

In some cases, it is necessary to galvanize the stainless steel coil to improve its corrosion resistance. If galvanizing is required, its process control will also have an impact on the corrosion resistance and surface quality of the coil.

🔘🟡🟠Shearing and coiling

Subsequent processing such as shearing and coiling of the coil will also affect the surface quality and dimensional accuracy. The processed stainless steel coil is subjected to subsequent processing such as shearing and coiling, and finally made into a stainless steel coil product that meets the requirements.

FAQ

Stainless steel coil is a popular material used in a wide range of applications, from construction to manufacturing to consumer goods. There are several different types of stainless steel coil available on the market, each with its own unique characteristics and properties.

One of the most common types of stainless steel coil is austenitic stainless steel, which is known for its high corrosion resistance and excellent formability. This type of stainless steel is often used in applications where resistance to corrosion is essential, such as in the food and beverage industry, chemical processing, and medical devices.

Another type of stainless steel coil is ferritic stainless steel, which is known for its high resistance to stress corrosion cracking and its excellent resistance to corrosion in general. This type of stainless steel is often used in applications where high strength and resistance to corrosion are critical, such as in automotive and aerospace applications.

Martensitic stainless steel is a third type of stainless steel coil, known for its high hardness and excellent wear resistance. This type of stainless steel is often used in applications where resistance to wear and abrasion is critical, such as in cutting tools and bearings.

Other types of stainless steel coil include duplex stainless steel, which has a higher strength than austenitic or ferritic stainless steel, and precipitation-hardening stainless steel, which is known for its high strength and resistance to corrosion.

When choosing a stainless steel coil for a particular application, it is important to consider the specific requirements of the application, such as the level of corrosion resistance needed, the desired strength and durability, and the desired formability or machinability. It is also important to work with reputable stainless steel suppliers who can provide high-quality materials and expert advice on the selection and use of stainless steel coil.

At stainless steel suppliers, we offer a wide range of stainless steel coil options to meet the needs of a variety of applications. Our experienced team can provide guidance and support throughout the selection and purchasing process, ensuring that our customers receive the best possible materials for their specific needs. Contact us today to learn more about our stainless steel coil options and how we can help with your next project.

Stainless steel coil are a popular choice for various industrial applications due to their corrosion resistance, strength, and durability. There are two primary manufacturing processes for producing stainless steel coil: hot-rolling and cold-rolling. In this article, we will discuss the differences between these two processes and their impact on the properties and applications of stainless steel coil.

Hot-rolled stainless steel coil are produced by heating a steel slab above its recrystallization temperature and passing it through a series of rollers. This process results in a product with a relatively rough surface finish and large thickness tolerances. The high temperature at which the steel is processed also results in a thick oxide layer on the surface, which provides some corrosion resistance but can also make further processing difficult.

In contrast, cold-rolled stainless steel coil are produced by passing a steel sheet or strip through a series of rollers at room temperature. This process results in a product with a smoother surface finish, tighter thickness tolerances, and improved mechanical properties. Cold-rolling also eliminates the oxide layer on the surface, resulting in improved surface quality and easier processing.

The differences between hot-rolled and cold-rolled stainless steel coil have implications for their applications. Hot-rolled coils are commonly used in applications where surface finish is not critical, such as structural components, whereas cold-rolled coils are used in applications where surface finish and dimensional tolerances are important, such as automotive components, household appliances, and electronic devices.

There are various types of stainless steel coil available on the market, including austenitic, ferritic, and martensitic stainless steels. Austenitic stainless steels are the most commonly used type of stainless steel coil, known for their excellent corrosion resistance, formability, and weldability. Ferritic stainless steels are less commonly used but offer good corrosion resistance and high-temperature strength. Martensitic stainless steels are primarily used for their high strength cold-rolled stainless steel coil are produced by rolling at room temperature, which results in a smoother and more polished surface finish. Cold-rolled coils also have tighter tolerances and more precise dimensions than hot-rolled coils, making them ideal for applications that require high precision and consistency.

In terms of cost, cold-rolled stainless steel coil are generally more expensive than hot-rolled coils due to the additional processing steps involved.

Stainless steel suppliers offer a wide range of both hot-rolled and cold-rolled stainless steel coil to meet the diverse needs of their customers. When selecting a supplier, it’s important to consider factors such as the supplier’s reputation, experience, and quality control measures.

Overall, the choice between hot-rolled and cold-rolled stainless steel coil depends on the specific application and the desired surface finish, dimensional accuracy, and cost requirements. Reputable stainless steel suppliers can provide expert guidance on selecting the right type of stainless steel coil for a given application, as well as ensuring that the material meets the required specifications and standards.

Stainless steel coil have become increasingly popular in various industries due to their unique properties and advantages over other materials. In this article, we will discuss the advantages of using stainless steel coil in various applications.

1. Corrosion Resistance: Stainless steel coil are highly resistant to corrosion. They have a thin layer of chromium oxide on their surface, which protects them from rust and other forms of corrosion. This makes them ideal for use in harsh environments, where exposure to moisture and chemicals can cause other materials to degrade.

2. Durability: Stainless steel coil are extremely durable and can withstand high levels of stress, making them ideal for use in demanding applications. They are resistant to wear and tear, as well as damage from impact, making them a popular choice in the manufacturing industry.

3. Aesthetics: Stainless steel coil have a sleek and modern appearance, making them a popular choice in interior design and architecture. They can be finished in a variety of ways, such as brushed, polished, or patterned, to create different visual effects.

4. Hygiene: Stainless steel coil are easy to clean and maintain, making them a popular choice in the food and beverage industry. They are also non-porous, meaning that they do not harbor bacteria, which is important in applications where cleanliness is critical.

5. Recyclability: Stainless steel coil are 100% recyclable, making them an environmentally friendly choice. They can be recycled over and over again without losing their quality or durability.

6. Heat Resistance: Stainless steel coil have a high resistance to heat, making them ideal for use in high-temperature applications such as industrial furnaces and boilers. They also have a low thermal expansion coefficient, which means they do not expand or contract significantly with changes in temperature.

7. Versatility: Stainless steel coil are versatile and can be used in a wide range of applications, including automotive, aerospace, construction, and medical industries. They are also compatible with a variety of welding and joining techniques, making them easy to work with.

8. Cost-Effective: Although stainless steel coil are initially more expensive than other materials, their long-term durability and low maintenance costs make them a cost-effective choice in the long run.

9. Availability: Stainless steel coil are readily available from stainless steel suppliers around the world. This means that they can be easily sourced for large-scale industrial projects.

10. Safety: Stainless steel coil are a safe choice in applications where safety is critical. They are non-toxic, non-combustible, and do not emit harmful gases or vapors, making them a popular choice in the chemical and pharmaceutical industries.

In conclusion, stainless steel coil offer a range of advantages over other materials, including corrosion resistance, durability, aesthetics, hygiene, recyclability, heat resistance, versatility, cost-effectiveness, availability, and safety. Stainless steel suppliers can provide a range of options to suit specific applications and requirements.

Choosing the right stainless steel coil for a specific application is critical for achieving optimal performance and durability. Here are some factors to consider when selecting a stainless steel coil:

Corrosion Resistance: The level of corrosion resistance required depends on the environment in which the coil will be used. For example, a coil used in a highly corrosive marine environment would require a higher level of corrosion resistance than one used in a mild, indoor environment.

Strength and Hardness: The strength and hardness of the coil should be appropriate for the application. A coil used in a high-stress application, such as a spring, would require a higher strength and hardness than one used in a decorative application.

Formability: Some applications require the coil to be formed into specific shapes or sizes. The formability of the coil depends on its composition and manufacturing process.

Surface Finish: The surface finish of the coil is important for aesthetic and functional purposes. A smooth surface finish is typically desired for decorative applications, while a rougher surface finish may be preferred for applications where grip is important.

Cost: The cost of the coil is an important consideration, and it should be balanced with the desired performance and durability.

When selecting a stainless steel coil, it is important to work with a reputable supplier who can provide guidance on the best options for your specific application. Here are some factors to consider when choosing a supplier:

Experience: Look for a supplier with a proven track record of supplying high-quality stainless steel coil for a variety of applications.

Certifications: Ensure that the supplier is certified to provide stainless steel coil that meet the required standards for your application.

Range of Products: Choose a supplier that offers a wide range of stainless steel coil options to ensure that you can find the right product for your needs.

In summary, selecting the right stainless steel coil for a specific application requires careful consideration of the desired properties and performance requirements. Working with a reputable supplier can help ensure that you choose the best product for your needs.

Stainless steel coil are a highly valued material due to their corrosion resistance, strength, and versatility. However, proper storage and handling are crucial to ensure their quality and prevent damage that can compromise their performance. In this article, we will discuss the best practices for storing and handling stainless steel coil.

First, it is important to store stainless steel coil in a clean, dry, and well-ventilated area. Exposure to moisture or contaminants such as dirt, dust, or oil can cause corrosion or contamination, which can compromise the quality of the material. Ideally, stainless steel coil should be stored indoors to protect them from the elements. If stored outdoors, they should be covered with a waterproof tarp or other protective covering to prevent moisture buildup.

Second, stainless steel coil should be stored in a way that minimizes the risk of damage. They should be stacked neatly on a flat surface, with spacers between each coil to prevent them from rubbing against each other. The weight of the coils should be evenly distributed, and they should be kept away from edges or other objects that could cause them to shift or fall.

Third, when handling stainless steel coil, it is important to use the right equipment and techniques. Forklifts or other material handling equipment should be used to move the coils, and care should be taken to avoid bumping or dropping them. Personnel handling the coils should wear gloves and other protective equipment to prevent damage or injury.

Fourth, it is important to inspect stainless steel coil regularly for signs of damage or corrosion. If any defects are found, they should be addressed immediately to prevent further damage. Any spills or contamination should also be cleaned up promptly to prevent corrosion or other damage.

In addition to these best practices, it is important to work with reputable stainless steel suppliers who can provide high-quality coils and expert advice on storage and handling. They can help you choose the right material for your application, and provide guidance on proper storage and handling to ensure the material performs at its best.

In conclusion, proper storage and handling of stainless steel coil is crucial to ensure their quality and prevent damage. By following best practices such as storing them in a clean, dry, and well-ventilated area, using the right equipment and techniques when handling them, and regularly inspecting them for signs of damage, you can ensure that your stainless steel coil perform at their best. Working with reputable stainless steel suppliers can also provide valuable guidance and support in this process.

Conclusion

In conclusion, stainless steel coil are an essential component in many industries, from construction to food processing, due to their durability, corrosion resistance, and versatility. There are many types of stainless steel coil available on the market, each with its unique properties and advantages. Choosing the right one for your specific application requires careful consideration of factors such as mechanical properties, chemical composition, and surface finish.

It is crucial to work with reputable stainless steel suppliers who can provide high-quality coils that meet your specifications and requirements. Additionally, proper handling and storage of stainless steel coil can ensure their longevity and prevent damage or contamination.

In summary, stainless steel coil are a reliable and valuable material in various applications, and understanding their properties and selection criteria can help optimize their use in your projects. With the support of trusted stainless steel suppliers, like HXSCO, you can confidently incorporate stainless steel coil into your manufacturing process and reap the benefits of this robust material.