China Aluminum bar supplier – wholesale aluminum bar

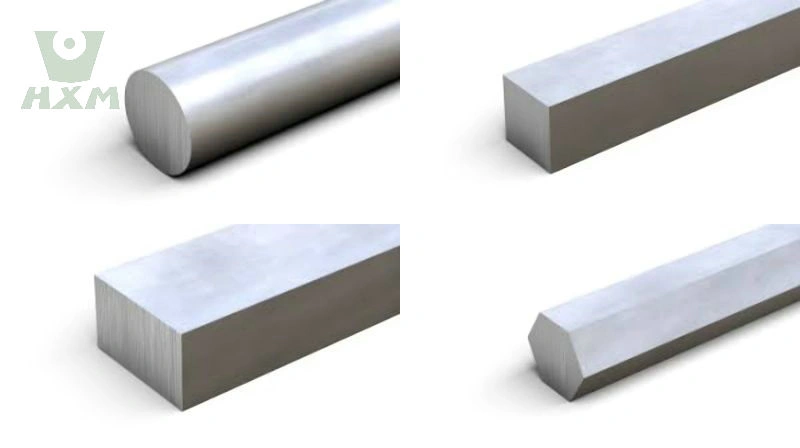

HXSCO is a professional aluminum bar and rod manufacturer and supplier. We are committed to providing high-quality aluminum rod and bar products, including aluminum round rods and bars, square bars, rectangular bars, hex bars, flat bars, and welding rods. As a leading aluminum bar manufacturer in China, our company has advanced production equipment and a strict quality control system to ensure that the products meet the most stringent standards in the global market.

Our factory provides wholesale aluminum bar services to customers worldwide to meet all kinds of needs. HXSCO is an SGS-ISO 9001-certified aluminum bar and rod manufacturer. Whether it is standard or custom aluminum rods and bars, we can provide high-quality aluminum materials and first-class services. HXSCO aluminum rod manufacturer looks forward to cooperating with you.

Contact UsAluminum bar specification

| Aluminium Bar Shape | Aluminium Alloy and Temper | Dimensions and Tolerances | Surface Finish |

|---|---|---|---|

| Flat Bar | Alloys: 2024, 6061, 6063, 6101, 6042, 6082, 7075; Temper: T6 (Solution Heat-Treated and Artificially Aged), T651 (Solution Heat-Treated, Stress-Relieved by Stretching and Artificially Aged) | Thickness: 0.125” to 7”; Width: up to 16”; Standard Length: 12′ | Bright Finish Mill Finish Anodized Color Finish |

| Hexagon Bar | Alloys: 2011, 2024, 6061, 6262, 7075; Temper: T3 (Solution Heat-Treated and Cold Worked), T351 (Solution Heat-Treated and Stress-Relieved by Stretching) | Across Flats: 0.375” to 3.5”; Standard Length: 12′ | |

| Round Bar | Alloys: 2011, 2024, 6061, 6262, 6042, 6082, 7075; Temper: T4 (Solution Heat-Treated and Naturally Aged), T6 | Diameter: 0.1875″ to 20”; Standard Length: 12′ | |

| Square Bar | Alloys: 2024, 6061, 6063, 6262, 6042, 6082, 7075; Temper: T5 (Cooled from an Elevated Temperature Shaping Process and Artificially Aged), T6 | Side Length: 0.375” to 8”; Standard Length: 12′ |

Processing methods of Aluminum Rod

Extruded Aluminum Rods

Extruded aluminum rods are made through the extrusion manufacturing process. A cylindrical aluminum billet is pushed through a die, which produces a uniform cross-section with a consistent shape. The process suits various shapes, including round, square, hexagonal, and rectangular rods. These rods have the following characteristics: consistency, cost-effectiveness, and versatility. Extruded aluminum rods have found their place in building frames, mechanical components, and everyday products.

Cold-Drawn Aluminum Rods

In contrast, cold-drawn aluminum rods undergo a different manufacturing process. The aluminum is deformed without heating by stretching and extruding it, resulting in a smoother and more precise surface finish. The notable features of cold-drawn rods are surface finish, tolerance control, and strength. These rods are often used in industries where precision and aesthetics are critical, including architectural decoration, automotive parts, and high-performance machinery.

Alloy Specialty Aluminum Rods

Alloy Specialty Aluminum Rods are rods made from specific aluminum alloys to meet precise requirements, such as enhanced strength, corrosion resistance, and electrical conductivity. The main feature of alloy specialty rods is their customized properties. For example, the 6061 aluminum rod is known for its strength and weldability, while the 7075 aluminum rod excels in applications that require high strength and durability. Alloy-specific aluminum rods are essential in aerospace, automotive, marine, and electronics fields.

Contact UsTypes of aluminum bar – HXSCO aluminum bar factory

| Type of Aluminum Rod | Dimension Specifications | Typical Length Options |

|---|---|---|

| Round Aluminum Rod | Diameter: 1/4 inch, 6mm, etc. | Standard lengths available, custom lengths can be manufactured |

| Square Aluminum Rod | Dimensions: 1/2 inch x 1/2 inch, 12mm x 12mm, etc. | Standard and custom lengths available |

| Hexagonal Aluminum Rod | Width across flats: 3/8 inch, 10mm, etc. | Standard and custom lengths typical |

| Rectangular Aluminum Rod | Dimensions: 1 inch x 2 inches, 25mm x 50mm, etc. | Custom lengths to meet specific requirements |

How Aluminum Bars Are Made

- Raw material preparation

First, we select high-quality aluminum ingots or scrap and pre-treat them to remove impurities.

- Melting

We then melt the clean aluminum in a furnace to form a liquid alloy. During this process, we can add other metals to obtain the desired alloy composition.

- Cutting

We cut solidified aluminum rods into standard or custom lengths to meet specifications.

- Post-treatment

Finally, we can apply surface treatments such as anodizing or painting to enhance corrosion resistance, aesthetics, or functionality. Quality control checks ensure that dimensions, composition, and mechanical properties meet industry standards or customer requirements.

What Is the Difference Between Aluminum Rod and Bar?

Shape and Dimensions

Aluminum Rod:

Typically refers to a cylindrical aluminum rod with a relatively small diameter, ranging from a few millimeters to a few centimeters.

Its shape is fixed as a cylinder with a uniform cross-section.

Aluminum Bar:

Encompasses aluminum bars with various cross-sectional shapes (round, square, rectangular, hexagonal, etc.).

Offers a wider range of dimensions, from smaller diameters or side lengths to larger sizes.

Can be customized to specific dimensions and shapes.

Applications

Aluminum Rod:

Due to its smaller size and higher precision, it’s often used in precision engineering, electronics, and as a raw material for further processing or components.

Aluminum welding rods are one of the more prominent categories of aluminum rods.

Aluminum Bar:

Because of its larger size and carrying capacity, it’s widely used in construction, machinery, and other industries as structural elements, supports, or raw materials for manufacturing.

Send Inquiry Now

Advantages of aluminum bar & rod

Advantages of Aluminum Bar

- Lightweight and high strength: The aluminum bar is ideal for applications that require strength without excessive weight, such as construction and aerospace.

- Corrosion resistance: The aluminum bar is naturally corrosion-resistant and suitable for harsh environments.

- Excellent thermal and electrical conductivity: Aluminum bar suits heat dissipation and electrical components.

- Versatility: With various shapes and sizes, it can adapt to many industries.

- Easy processing: The aluminum bar is easy to process, form, and weld.

Advantages of Aluminum Rods

- High Precision: Aluminum rods are usually produced with tight tolerances to suit precision applications.

- Consistent Quality: Suitable for parts that require uniformity and dimensional accuracy.

- Strength and Durability: Aluminum rods can withstand pressure and maintain structural integrity.

- Corrosion Resistance: Similar to bars, rods also have good corrosion resistance.

- Customizable: Available in different diameters and lengths to meet specific requirements.

Uses for Aluminum Bar and rod

Structural Support

Aluminum Bar is strong yet lightweight, making it great for structures like bridges and buildings.

Electrical Components

Aluminum Bars and rods conduct electricity well, so they’re used in wiring and other electrical parts.

Transportation

Aluminum bars and rods help make cars, planes, and ships lighter and more fuel-efficient.

Manufacturing

These materials can be easily shaped and cut to make all sorts of factory parts and products.