What Is 4140 Alloy Steel?

In the dynamic landscape of industrial materials, 4140 Alloy Steel emerges as a stalwart, recognized for its exceptional properties and versatile applications. Let’s delve into the intricacies that define this alloy, understanding its composition and the key attributes that render it indispensable.

Definition and Composition

At its core, 4140 Alloy Steel is a chromium-molybdenum alloy steel with a substantial carbon content. This alloy, conforming to the ASTM A29/A29M standard, is meticulously crafted to exhibit remarkable strength, toughness, and wear resistance. The defining elements within its composition include:

Carbon (C): Ranging from 0.38% to 0.43%, the carbon content contributes to the alloy’s hardenability and strength.

Manganese (Mn): Present at 0.75-1.00%, manganese enhances hardenability, mechanical properties, and overall steel toughness.

Phosphorus (P) and Sulfur (S): Restricted to maximum values of 0.035% and 0.040%, respectively, to ensure the cleanliness and purity of the steel.

Silicon (Si): Within the range of 0.15-0.35%, silicon aids in deoxidation and contributes to the overall strength of the alloy.

Chromium (Cr): Falling between 0.80% and 1.10%, chromium enhances hardenability, wear resistance, and corrosion resistance.

Molybdenum (Mo): Present at 0.15-0.25%, molybdenum significantly contributes to the alloy’s strength at elevated temperatures.

This meticulous combination of elements results in a steel alloy that exhibits not only a formidable resistance to wear and abrasion but also a capacity for maintaining its structural integrity under challenging conditions.

Key Properties that Make 4140 Alloy Steel Desirable

Exceptional Strength and Toughness

The synergy of carbon, manganese, and chromium imparts unparalleled strength to 4140 Alloy Steel, making it suitable for applications demanding robust structural integrity.

Versatile Heat Treatment

The alloy’s composition allows for various heat treatment options, offering flexibility to achieve desired mechanical properties such as hardness, toughness, and tensile strength.

High Fatigue Strength

4140 Alloy Steel demonstrates resilience under cyclic loading, making it a preferred choice in components subjected to repeated stress, such as gears and shafts.

Good Impact Resistance

The alloy’s toughness, coupled with its ability to absorb impact energy, makes it a reliable choice for applications where sudden shocks or impacts are prevalent.

Machinability and Weldability

Despite its high strength, 4140 Alloy Steel maintains favorable machinability, enabling efficient fabrication processes. Additionally, its weldability ensures adaptability to diverse manufacturing requirements.

Corrosion Resistance

The chromium content provides a level of corrosion resistance, adding to the alloy’s durability in various environmental conditions.

Wide Range of Applications

From aerospace components and oil and gas industry tools to automotive parts and general machinery, 4140 Alloy Steel finds its prowess in an extensive array of applications, attesting to its versatility.

As reputable Alloy Steel Suppliers, HXSCO recognizes the paramount importance of delivering high-quality 4140 Alloy Steel that aligns with stringent industry standards. Our commitment extends beyond mere supply— we aim to empower our clients with a profound understanding of the alloys we offer, fostering informed decision-making and ensuring the seamless integration of our products into diverse industrial landscapes.

Technical Specifications

In the realm of industrial materials, a nuanced understanding of technical specifications is paramount, and 4140 Alloy Steel stands as an exemplar in this regard. Let’s embark on a comprehensive exploration, breaking down the chemical composition, delving into mechanical properties, and drawing insightful comparisons that underscore the distinctiveness of 4140 Alloy Steel.

Detailed Breakdown of the Chemical Composition

The DNA of 4140 Alloy Steel lies in its meticulously crafted chemical composition, a harmonious blend of elements that bestows upon it a unique set of properties. The following is a detailed breakdown of the key constituents:

Carbon (C): Constituting 0.38-0.43%, carbon plays a pivotal role in enhancing the hardness and strength of the alloy.

Manganese (Mn): Present at 0.75-1.00%, manganese contributes to hardenability, augmenting the alloy’s mechanical properties.

Phosphorus (P) and Sulfur (S): Restricted to maximum values of 0.035% and 0.040%, respectively, these elements are minimized to ensure the alloy’s purity and integrity.

Silicon (Si): Falling within the range of 0.15-0.35%, silicon aids in deoxidation and fortifies the alloy’s overall strength.

Chromium (Cr): Ranging from 0.80% to 1.10%, chromium imparts corrosion resistance, wear resistance, and heightened hardenability.

Molybdenum (Mo): Present at 0.15-0.25%, molybdenum significantly elevates the alloy’s strength, particularly in high-temperature environments.

This intricate composition lays the foundation for 4140 Alloy Steel’s exceptional performance across a myriad of industrial applications.

Mechanical Properties and Performance Characteristics

Tensile Strength

4140 Alloy Steel boasts an impressive tensile strength, typically ranging from 850 MPa to 1000 MPa, rendering it robust and resilient in demanding structural applications.

Yield Strength

The yield strength of 4140 Alloy Steel is noteworthy, ranging from 640 MPa to 900 MPa. This property signifies the amount of stress the material can withstand before permanent deformation.

Hardness

Achieving a Rockwell hardness of 22 HRC to 32 HRC after quenching and tempering, 4140 Alloy Steel strikes a balance between hardness and toughness, making it suitable for diverse applications.

Impact Resistance

The alloy exhibits excellent impact resistance, making it suitable for components subjected to sudden shocks or dynamic loads.

Fatigue Strength

4140 Alloy Steel showcases high fatigue strength, making it an ideal choice for components exposed to cyclic loading, such as gears and shafts.

Comparison with Other Types of Alloy Steel or Traditional Steels

In the landscape of alloy steels, 4140 stands out as a versatile and high-performance material. When compared with traditional steels and other alloy steels, several distinguishing features come to the forefront:

Versatility

4140 Alloy Steel demonstrates versatility in a wide range of applications, from aerospace components to automotive parts, showcasing its adaptability across industries.

Heat Treatment Response

The alloy responds well to various heat treatment processes, providing engineers and manufacturers with flexibility in achieving desired mechanical properties.

Machinability

Despite its high strength, 4140 Alloy Steel maintains favorable machinability, easing the manufacturing process.

As reputable Alloy Steel Suppliers, HXSCO ensures that the 4140 Alloy Steel supplied adheres not only to these technical specifications but also meets the dynamic and stringent requirements of diverse industries. Our commitment is rooted in providing not just a product but a solution—a material that transcends expectations and elevates the performance of our clients’ applications.

Applications Of Carbon Steel Plate

Automotive Industry

The automotive sector relies on 4140 alloy steel for critical components that require high strength, durability, and wear resistance. For instance, crankshafts in engines are often made from 4140 alloy steel due to its excellent combination of toughness and hardness. Additionally, suspension components, such as axles and control arms, benefit from the superior properties of 4140 alloy steel, ensuring optimal performance and safety on the road.

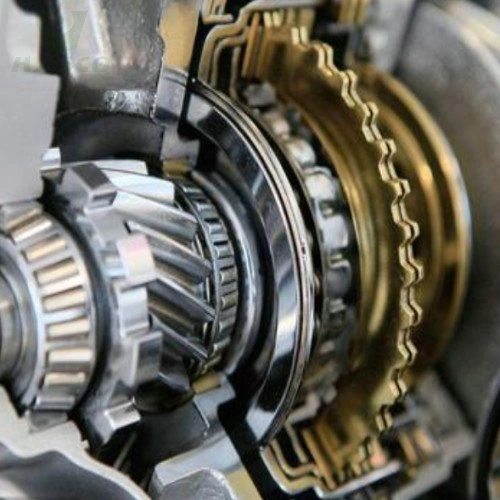

Case Study: A renowned automotive manufacturer incorporated 4140 alloy steel in their transmission shafts. The use of 4140 alloy steel ensured a high-strength and wear-resistant solution, allowing the transmission system to handle the demands of heavy-duty applications and enhance overall vehicle performance.

Aerospace Industry

In the aerospace industry, where reliability and performance are paramount, 4140 alloy steel is utilized in various applications. It is commonly employed in the construction of landing gears, engine components, and structural parts. The exceptional strength, toughness, and high-temperature resistance of 4140 alloy steel make it suitable for handling extreme conditions and ensuring the safety of aircraft.

Case Study: An aircraft manufacturer utilized 4140 alloy steel in the production of landing gear components. The use of 4140 alloy steel provided the necessary strength and fatigue resistance, ensuring the landing gear’s ability to withstand repeated stresses during takeoff, landing, and ground operations. This contributed to the overall reliability and safety of the aircraft.

Machinery and Tooling

4140 alloy steel is widely used in the machinery industry for manufacturing shafts, tooling, and machine components that require high strength, hardness, and wear resistance. Its superior properties make it ideal for applications where heavy loads, abrasion, and impact forces are involved.

Case Study: A machinery manufacturer incorporated 4140 alloy steel in the production of gears for heavy machinery. The excellent combination of strength, toughness, and wear resistance offered by 4140 alloy steel ensured the gears’ ability to withstand heavy loads and prolonged operation without failure or excessive wear. This resulted in enhanced efficiency, reduced downtime, and increased overall productivity.

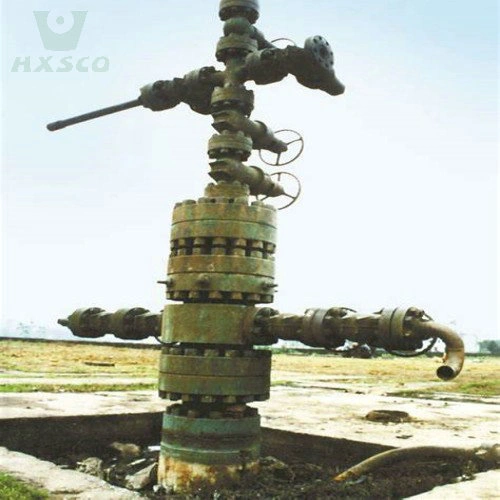

Oil and Gas Industry

The oil and gas sector relies on 4140 alloy steel for various applications, including drill collars, drill rods, and other components used in drilling operations. The high tensile strength, hardness, and resistance to wear and corrosion make 4140 alloy steel well-suited for the demanding conditions encountered in oil and gas exploration and production.

Case Study: An oil and gas company utilized 4140 alloy steel in the manufacture of drill collars. The use of 4140 alloy steel provided the necessary strength and durability to withstand the extreme forces and abrasive environments encountered during drilling operations. This contributed to the longevity and efficiency of the drilling equipment.

Case Studies Or Success Stories

In the dynamic landscape of industrial applications, the true testament to the prowess of 4140 Alloy Steel lies in its real-world performance. As a leading force in the market, alloy steel suppliers HXSCO takes pride in presenting compelling case studies and testimonials that illuminate the success stories of 4140 Alloy Steel in diverse applications, underscoring the reliability and excellence delivered by HXSCO as trusted Alloy Steel Suppliers.

Real-World Examples of Successful Applications of 4140 Alloy Steel Supplied by HXSCO

Case Study 1: Aerospace Precision Gears

In a high-stakes aerospace project, alloy steel suppliers HXSCO supplied precision gears forged from 4140 Alloy Steel. The demanding requirements of aerospace applications necessitated a material that could withstand extreme forces, maintain dimensional stability, and exhibit exceptional fatigue resistance. The 4140 Alloy Steel gears not only met but exceeded these expectations, contributing to the seamless operation of critical components in the aerospace machinery.

Case Study 2: Oil and Gas Drilling Components

In the oil and gas industry, where conditions are harsh and demanding, HXSCO’s supply of 4140 Alloy Steel components proved instrumental. From drill collars to downhole tools, the alloy exhibited superior strength and corrosion resistance, ensuring the longevity and reliability of drilling operations in challenging environments. The success of these applications speaks volumes about the adaptability and resilience of 4140 Alloy Steel supplied by alloy steel suppliers HXSCO.

Case Study 3: Automotive Transmission Shafts

Automotive transmission systems demand materials that can endure the rigors of constant motion and varying loads. HXSCO supplied 4140 Alloy Steel for transmission shafts, contributing to enhanced durability and performance. The alloy’s excellent machinability facilitated the manufacturing process, aligning with the efficiency requirements of the automotive industry.

These real-world examples underscore the versatility and reliability of 4140 Alloy Steel across diverse sectors, demonstrating its ability to elevate performance in critical applications.

Comparison with Other Types of Alloy Steel or Traditional Steels

In the landscape of alloy steels, 4140 stands out as a versatile and high-performance material. When compared with traditional steels and other alloy steels, several distinguishing features come to the forefront:

Versatility

4140 Alloy Steel demonstrates versatility in a wide range of applications, from aerospace components to automotive parts, showcasing its adaptability across industries.

Heat Treatment Response

The alloy responds well to various heat treatment processes, providing engineers and manufacturers with flexibility in achieving desired mechanical properties.

Machinability

Despite its high strength, 4140 Alloy Steel maintains favorable machinability, easing the manufacturing process.

As reputable Alloy Steel Suppliers, HXSCO ensures that the 4140 Alloy Steel supplied adheres not only to these technical specifications but also meets the dynamic and stringent requirements of diverse industries. Our commitment is rooted in providing not just a product but a solution—a material that transcends expectations and elevates the performance of our clients’ applications.

Testimonials from Satisfied Clients Showing the Reliability of HXSCO’s Products

Precision Engineering Firm

“We have been sourcing 4140 Alloy Steel from alloy steel suppliers HXSCO for several years, and their commitment to quality and reliability is unmatched. The material consistently meets our stringent specifications, and their customer service is exemplary. HXSCO has become our go-to partner for alloy steel supplies, and their 4140 Alloy Steel has played a pivotal role in the success of our precision engineering projects.”

Oil and Gas Exploration Company

“In the challenging landscape of oil and gas exploration, reliability is non-negotiable. Alloy steel suppliers HXSCO has been a reliable ally, supplying us with 4140 Alloy Steel components that have demonstrated exceptional performance in the field. Their attention to detail, adherence to industry standards, and timely deliveries make them a preferred partner in our operations. We trust HXSCO to provide the quality we need for our critical applications.”

Automotive Manufacturing Company

“As an automotive manufacturer, we demand materials that can withstand the dynamic demands of our industry. HXSCO’s 4140 Alloy Steel has been a game-changer for us. The material’s combination of strength, machinability, and durability has significantly improved the performance of our transmission shafts. Working with HXSCO has not only elevated the quality of our products but also streamlined our supply chain.”

These testimonials stand as a testament to the satisfaction and trust instilled by HXSCO’s commitment to delivering top-notch 4140 Alloy Steel. As Alloy Steel Suppliers, we take pride in not just supplying materials but in contributing to the success and excellence of our clients’ ventures.

Production Process

1. Raw Material Selection

The journey of 4140 Alloy Steel begins with the careful selection of raw materials. High-quality steel billets, rich in the essential elements—carbon, manganese, chromium, and molybdenum—are chosen to ensure the alloy’s integrity and performance.

2. Melting and Alloying

The selected raw materials undergo a precise melting process in electric arc furnaces. During this phase, alloying elements are carefully added to achieve the exact chemical composition required for 4140 Alloy Steel. This meticulous alloying process is critical to ensuring the alloy’s desired properties.

3. Continuous Casting

The molten steel is then cast into billets through continuous casting, a method that ensures uniformity and eliminates impurities. These billets serve as the foundation for subsequent forging and shaping processes.

4. Forging

The hot forging process transforms the steel billets into the desired shapes, such as round bars, flat bars, or other specified forms. This step is crucial for refining the microstructure of the alloy, enhancing its mechanical properties.

5. Heat Treatment

Heat treatment is a defining step in the production of 4140 Alloy Steel. The material undergoes a specific sequence of heating and cooling processes to achieve the desired hardness, toughness, and overall mechanical properties. This phase demands precision and adherence to strict temperature and time parameters.

6. Machining and Finishing

The machinability of 4140 Alloy Steel allows for precise shaping and finishing. HXSCO employs state-of-the-art machining techniques to meet the exact specifications of clients, ensuring the alloy is ready for its intended applications.

HXSCO’s Advanced and Efficient Production Methods

As industry leaders and trusted Alloy Steel Suppliers, HXSCO places a paramount emphasis on adopting advanced and efficient production methods. Our commitment to delivering excellence is reflected in the following aspects of our manufacturing process:

1. Technology Integration

HXSCO leverages cutting-edge technologies in every phase of production, from the precise control of electric arc furnaces to the implementation of sophisticated heat treatment processes. This technology integration ensures consistency, quality, and efficiency in our production.

2. Quality Assurance

Rigorous quality control measures are ingrained in our production ethos. We adhere to international standards, conducting thorough inspections and testing at each stage of the manufacturing process. This commitment to quality assurance guarantees that every batch of 4140 Alloy Steel meets or exceeds industry specifications.

3. Customization Capabilities

Recognizing the diverse needs of our clients, HXSCO offers customization options for 4140 Alloy Steel. From varying dimensions to specific heat treatment requirements, our production methods are flexible, catering to the unique demands of different industries.

4. Environmental Responsibility

HXSCO is committed to sustainable and environmentally responsible manufacturing. Our production facilities adhere to eco-friendly practices, ensuring that the production of 4140 Alloy Steel aligns with global environmental standards.

In conclusion, the manufacturing process of 4140 Alloy Steel is a harmonious blend of tradition and innovation. As Alloy Steel Suppliers, HXSCO stands at the forefront of this process, weaving advanced technologies with a commitment to precision and excellence. The result is a product that not only meets the stringent demands of industries but also reflects our dedication to pushing the boundaries of what is achievable in alloy steel production.

Conclusion

In the realm of industrial excellence, where precision meets resilience, the narrative of 4140 Alloy Steel unfolds as a testament to innovation and reliability. As we conclude this exploration, the significance of choosing the right alloy steel suppliers cannot be overstated.

At HXSCO, we take pride in being more than just alloy steel suppliers—we are architects of solutions, partners in progress, and custodians of quality. Our commitment to delivering 4140 Alloy Steel of unparalleled excellence is rooted in a legacy of precision manufacturing and a forward-looking approach to technology.

The journey of 4140 Alloy Steel, from the selection of raw materials to the culmination of advanced production processes, mirrors our dedication to providing a product that transcends expectations. As you venture into the dynamic landscape of industrial applications, we invite you to consider not just the steel but the partnership that comes with it.

Choosing HXSCO as your alloy steel supplier means embracing a synergy of quality, customization, and environmental responsibility. Our advanced and efficient production methods ensure that each batch of 4140 Alloy Steel meets the highest industry standards, empowering your projects with the strength, durability, and versatility that this alloy embodies.

In a world where precision matters, where the right material can be the cornerstone of success, alloy steel suppliers HXSCO stands as your ally. As you embark on endeavors that demand the robustness of 4140 Alloy Steel, trust in us as more than alloy steel suppliers—trust in us as collaborators in your journey towards industrial excellence.

Your success is our success, and as we forge ahead into the future of alloy steel innovation, we remain steadfast in our commitment to being the preferred choice for those who seek not just steel but a strategic partnership. Elevate your projects, enhance your applications, and choose 4140 Alloy Steel with the confidence that comes from choosing alloy steel suppliers HXSCO—where excellence is not just a promise, but a legacy.