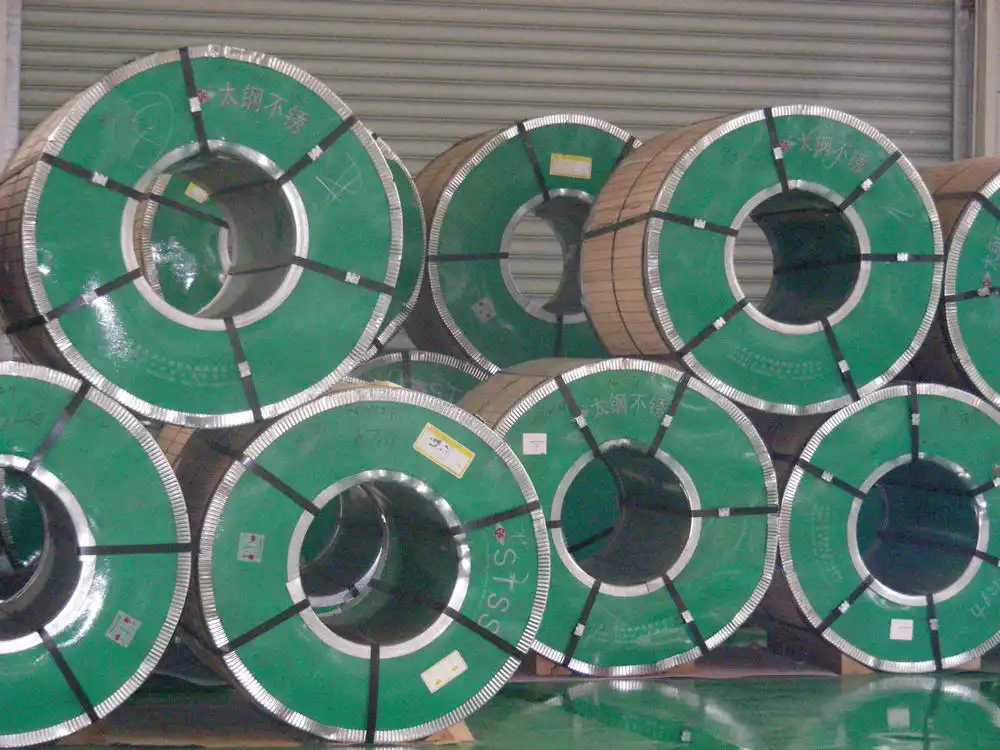

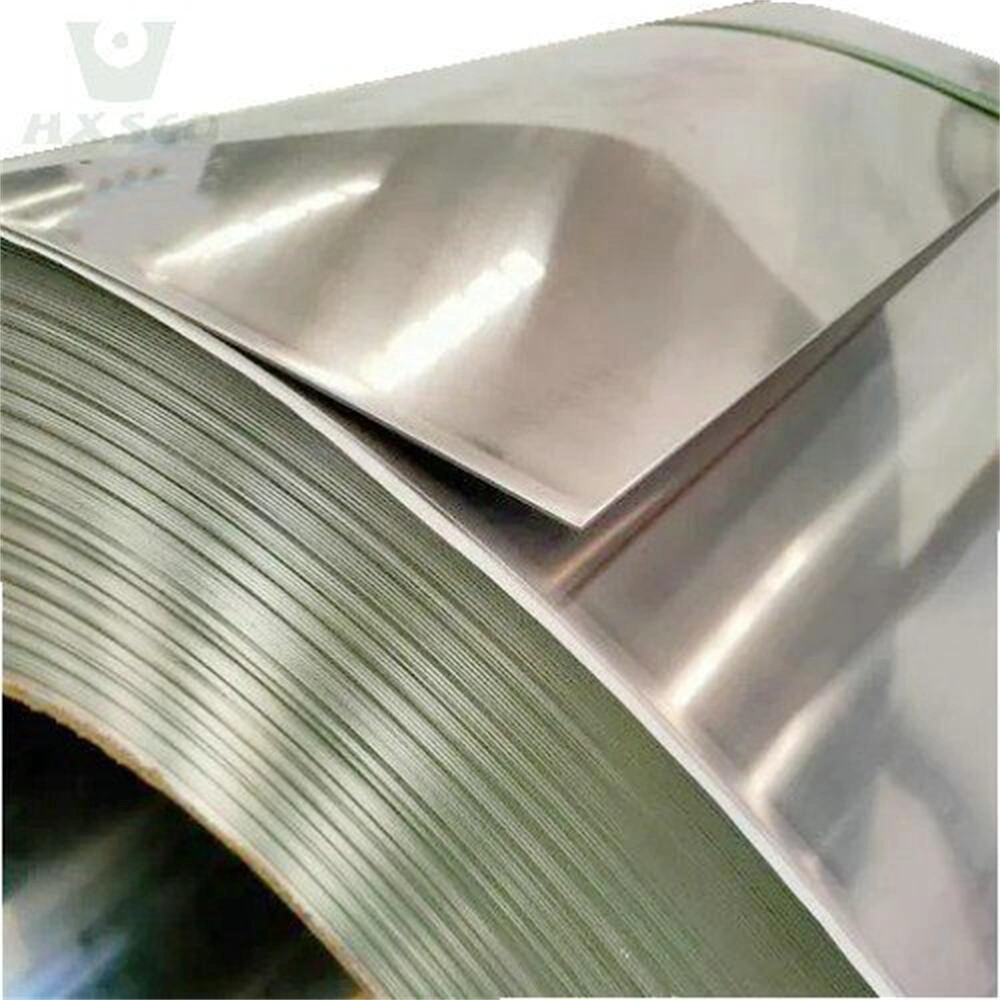

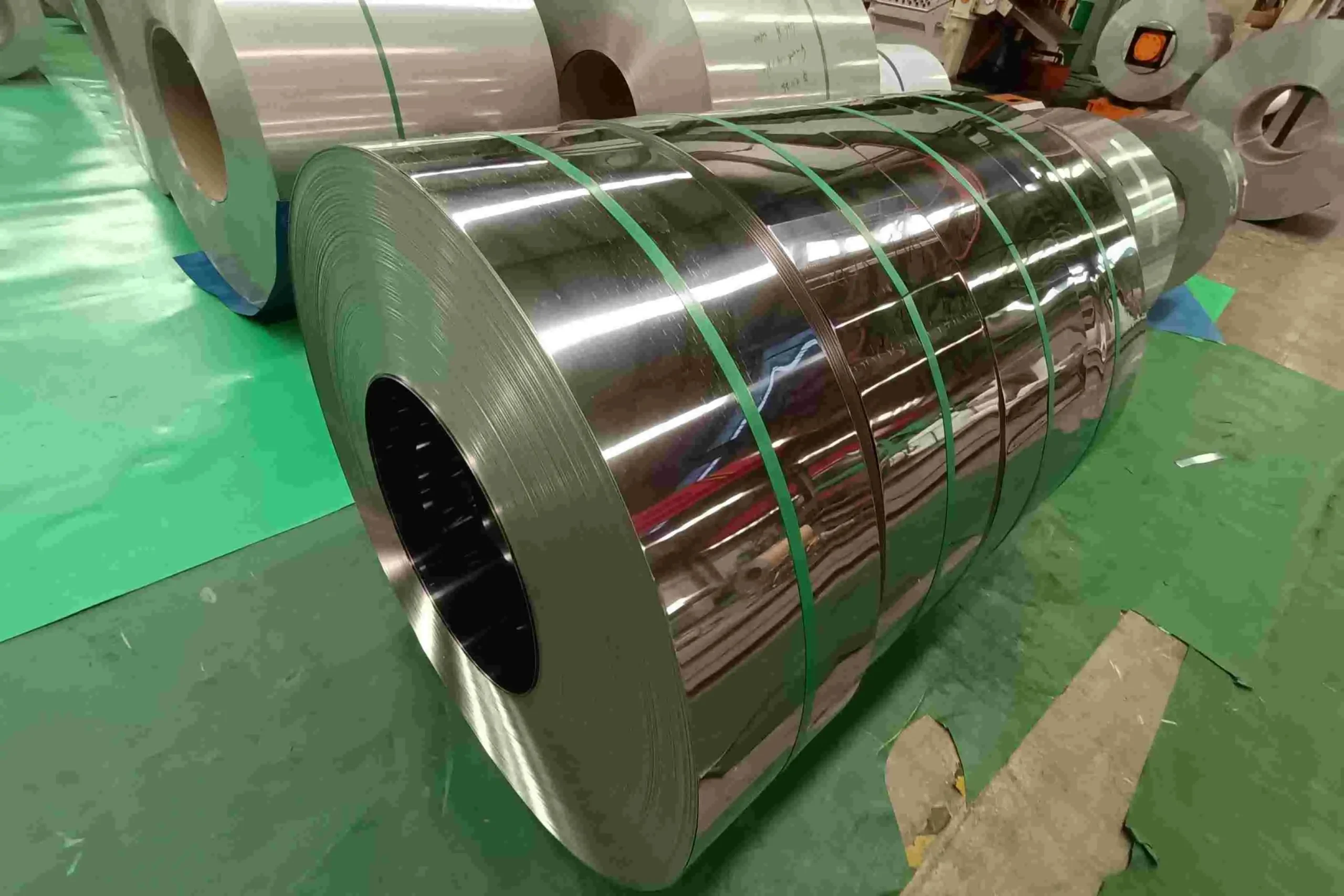

Stainless Steel Coil Manufacturer in China

Stainless Steel Sheet Specifications

| Specification | Details |

|---|---|

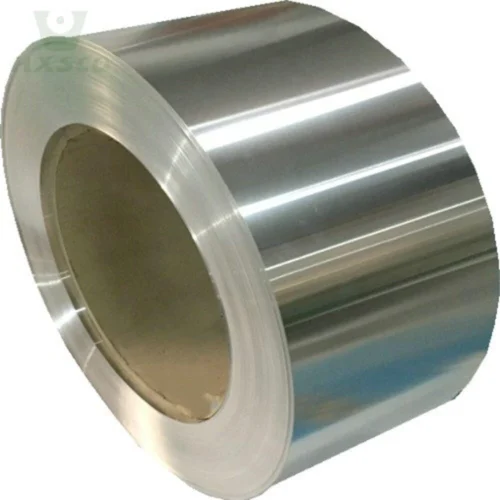

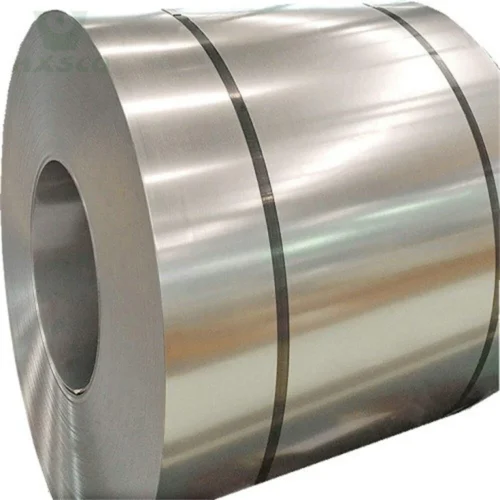

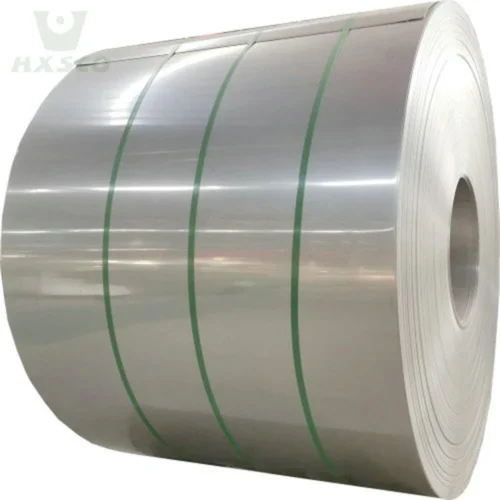

| Material | Stainless Steel Coil |

| Thickness | Cold Rolled: 0.3 - 3mm; Hot Rolled: 3 - 60mm |

| Width | Usually 1000mm to 2000mm |

| Length | Customized according to customer requirements, usually ranging from a few meters to tens of meters |

| Surface treatment | 2B, 2D, BA, No.1, No.3, No.4, No.5, No.8, 8K, HL and other different surface treatment methods |

| Origin | China |

| Shipping | 3-15 Days |

| Price | Depending on the order |