seamless Stainless Steel Pipe&Tube

Standard: ASTM A213 A511 SA312

OD: 6mm – 530mm, customizable

WT: 0.8mm – 34mm, customizable

Length: 2000mm – 12000mm, customizable

Grade: 201, 202, 304, 304L, 316, 316L, 321, 409, 430 etc.

Finish: Mill, 2B, BA, 240GRIT, GRIT etc.

Shape: round, square, rectangular etc.

leading seamless stainless steel pipe manufacturer and supplier

HXCSO is a leading manufacturer and supplier of seamless stainless steel pipes and tubes. We understand the critical role of stainless steel seamless pipes in modern industry. Thus, we adhere to strict quality control measures to ensure that every pipe meets the highest quality standards.

HXCSO has passed SGS-ISO:9001 quality management system certification. This certification is a strong testament to our commitment to quality. We know that quality is a business’s lifeline, and we always put it first. Every step is strictly monitored, from raw material procurement and manufacturing to final inspection. Strict inspection ensures the stability and reliability of our seamless pipes and tubes.

Stainless steel seamless pipes have excellent corrosion, high temperature, and high-pressure resistance. They are widely used in various fields, such as petroleum, the chemical industry, medical treatment, food, machinery, etc. HXCSO’s stainless steel seamless pipes have superior physical properties, good aesthetics, and precise dimensions. These excellent properties meet diverse and demanding industrial requirements.

Our seamless steel pipes are produced using advanced manufacturing technology and equipment. And we use precision rolling and cold drawing processes to ensure that the inner and outer walls of the steel pipe are smooth and flawless. These processes extend the service life and safety of seamless pipes and tubes. Besides, we provide stainless steel seamless pipes in various specifications and materials to meet the needs of different customers. HXCSO looks forward to cooperating with more customers to create a prosperous future.

Contact UsDifferent Grades Of seamless Stainless Steel Pipe&Tube

304 seamless SS pipe&tube

304 seamless stainless steel pipe is known for its corrosion resistance and ease of fabrication. This kind of pipe has better pressure-bearing capacity and a beautiful appearance. So, they have a wide range of applications in the chemical and medical industries.

Send Inquiry Now

316L seamless SS pipe&tube

316L stainless steel seamless pipe is a high-quality SS pipe. This type of stainless steel also contains molybdenum, which provides excellent resistance to chloride corrosion. 316L SS seamless tube is the first choice for marine engineering and harsh chemical environments.

Send Inquiry Now

321 seamless SS pipe&tube

321 stainless steel seamless pipe is a high-temperature-resistant stainless steel material pipe. This material maintains good stability and corrosion resistance at high temperatures. 321 stainless steel seamless tube is suitable for applications requiring high-temperature stability.

Send Inquiry Now

409 seamless SS pipe&tube

409 seamless stainless steel pipe is cost-effective and practical. It has some corrosion resistance, especially in mild environments. So, 409 SS seamless tubes are suitable for common applications such as automotive exhaust systems and building exterior walls.

Send Inquiry NowHot rolling process: Hot rolling is a common method for manufacturing stainless steel seamless pipes. During this process, the heated steel billet is placed in a rolling mill at high temperatures. Through a series of rolling and drawing steps, the blank is gradually formed into a tubular shape and reaches the desired size and thickness.

Cold drawing (cold rolling) process: Cold drawing is performed at room temperature, where a drawing machine pulls the tube blank through a die. This process reduces the diameter of the pipe and increases its length. Cold drawing improves the size and surface finish of steel pipes. It also enhances the metal’s strength.

Extrusion process: The heated metal blank is placed into a closed extrusion barrel during the extrusion process. It is extruded through a die with a specific cross-sectional shape by applying pressure. This method is suitable for producing seamless tubes with uniform wall thickness and complex cross-sectional shapes.

Perforation process: Perforation involves perforating a heated round billet using a perforator and a mandrel. The tubular shape is formed by pushing it through a mold with a mandrel. This technology is generally used to produce large-diameter, thick-walled seamless pipes.

Different production processes of stainless steel seamless pipes

Each process has its unique advantages and application areas. Manufacturers choose the appropriate production technique based on the specific requirements and applications of their stainless steel seamless pipes.

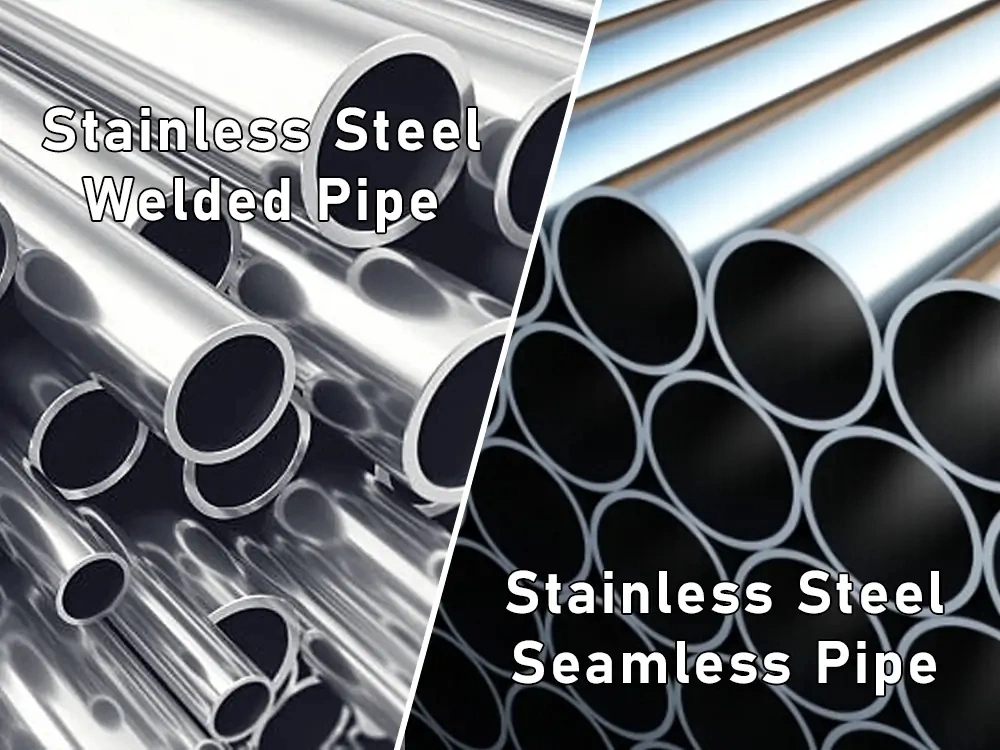

stainless steel seamless pipe VS stainless steel welded pipe

Manufacturing: Stainless steel seamless pipes are mainly produced through hot rolling, cold drawing, cold rolling, extrusion, perforation, and other processes. These processes allow metal materials to be formed into specific shapes and sizes at high or room temperatures. The result is pipes with uniform wall thickness and excellent surface quality. In contrast, stainless steel welded tube is made by bending steel plates or strips into circles or squares and then welding them together.

Performance characteristics: Stainless steel seamless pipes have high pressure-bearing capacity and good corrosion resistance because they have no welds. This feature makes them better for use in high-pressure, high-temperature, or corrosive places. Stainless steel welded pipes and tubes also have good corrosion resistance and strength. Yet, due to the welds, their pressure capacity may be slightly lower than that of seamless pipes.

Appearance and application: Stainless steel seamless pipe typically has a smoother surface and better dimensions. It is ideal for applications where pipe performance and looks matter, including the petroleum, chemical, and medical fields. Yet, stainless steel welded pipes and tubes are more flexible. We can make them into many shapes and sizes. They have many uses in construction, decoration, and machinery.

Contact UsAdvantages of stainless steel seamless pipes&tubes

Corrosion resistant

Stainless steel seamless pipes have excellent corrosion resistance. Due to their high chromium and nickel content, these pipes can withstand corrosion from various chemicals, including acids and alkalis. Thus, seamless pipes perform well in harsh environments.

High intensity

The structural characteristics of seamless pipes give them superior strength and pressure resistance. The pipe has no welds and a uniform wall. So it can withstand higher pressure and load. It is good for high-pressure and high-temperature conditions.

Excellent machinability

Stainless steel seamless pipes have excellent machinability and plasticity. Whether cold or hot working, seamless pipes maintain good shape and dimensional stability. This facilitates next processing operations such as cutting, bending, and welding.

Applications of stainless steel seamless pipes&tubes

Oil and Natural Gas Transmission:

Stainless steel seamless pipes can handle high pressure and resist corrosion. They are commonly used in the high-pressure, long-distance oil and gas transportation systems. These pipes ensure safe and stable operation.

Chemical Corrosion-Resistant Pipelines:

In chemical production, stainless steel seamless pipes can effectively resist various corrosive media. This characteristic makes seamless tubes ideal for constructing corrosion-resistant fluid transport piping systems.

High-Temperature Furnace Tubes:

Seamless pipes maintain stable performance in high-temperature environments. They are often used in the piping systems of furnaces and heat exchangers to ensure the efficient operation of these high-temperature equipment.

High-Precision Fluid Systems:

Seamless pipes have high dimensional accuracy and smooth surfaces. These qualities make them ideal for high-precision fluid control systems in precision instruments and medical equipment.

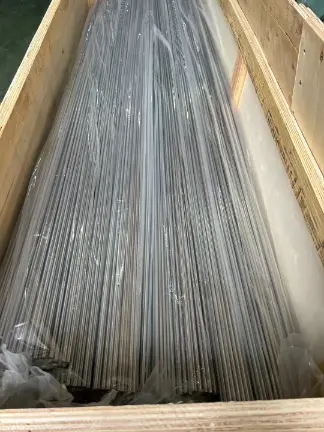

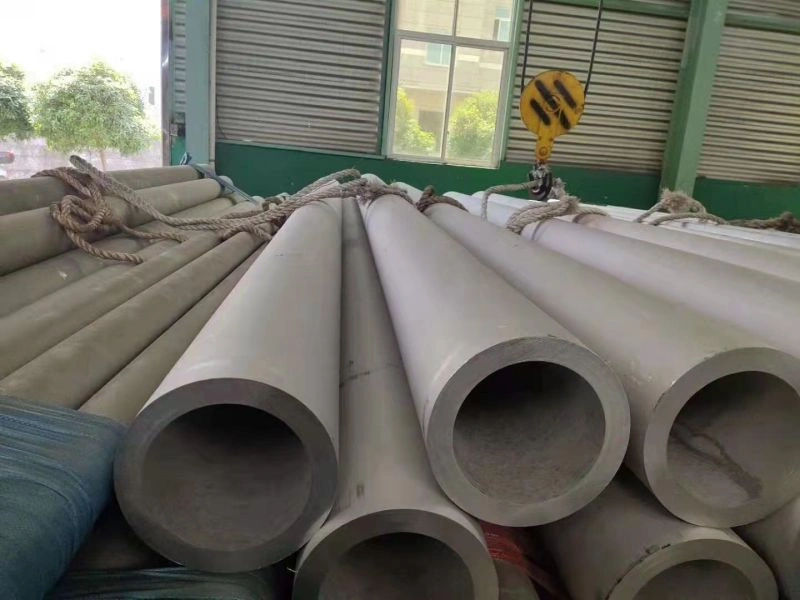

Packaging of seamless Stainless Steel Tubes/Pipes:

HXSCO uses high-quality packaging materials combined with advanced packaging technology. This packaging ensures that each steel pipe is firm and stable in the packaging. It prevents collision, scratching, and bending during transport.

Additionally, we understand that our customers’ needs vary. That’s why we offer custom packaging services. Customers can choose the best packaging based on product traits, transport needs, and final use. Our team will closely with customers to ensure custom packaging meets their needs.

We also provide customized marking services. As an important part of product identification, marks can help customers identify and manage products and enhance brand image. We can design and produce markings with personalized elements according to customer needs to make the product more identifiable and attractive.

In short, we can provide the best packaging solutions for welded stainless steel seamless pipes. We believe that customers will enjoy a satisfactory shopping experience through our efforts.

Stainless Steel Seamless Tube delivery pictures