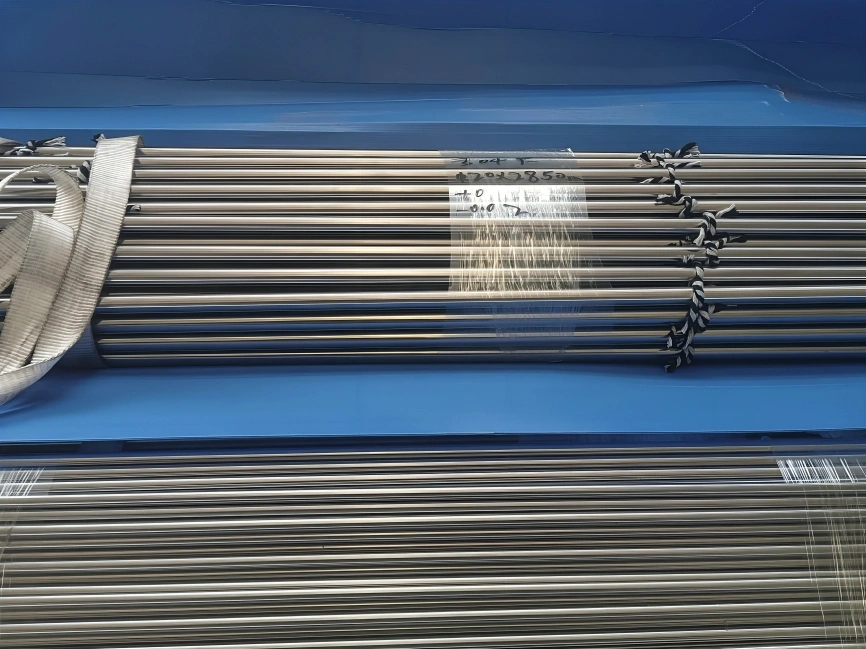

Stainless Steel Bar Manufacturer in China

HXSCO is a well-known stainless steel bar manufacturer and supplier with over a decade of experience. We are committed to providing high-quality stainless steel bar products to various industries such as construction, defense, industrial and manufacturing. Our warehouse has a rich inventory of stainless steel bars and is capable of producing high-grade materials that meet international standards. A range of custom stainless steel bars and wholesale stainless steel bar options ensure that we meet the various needs of our customers.

We offer stainless steel bars in popular grades, such as 303, 304, and 316, which have excellent corrosion resistance, high machinability, and good weldability. These products are ideal for a variety of applications, such as structural construction, engineering projects, machinery manufacturing, and high-temperature environments. Our China stainless steel bar production facilities are equipped with advanced technology to ensure precision and consistency.

Our SGS ISO 9001 certification indicates that our production processes and products meet strict international requirements. Whether you are looking for custom stainless steel bar solutions or reliable wholesale stainless steel bar supply, we ensure timely delivery and excellent service. HXSCO is your preferred stainless steel bar manufacturer, supplier, and company. For more information or to inquire about our products and services, please feel free to contact us. HXSCO is always ready to provide expert consultation and technical support.

Stainless Steel Rods of Different Grades

303 Stainless Steel Bar

303 Stainless Steel Bar is a highly machinable austenitic stainless steel designed for applications that require extensive machining. It is modified by adding sulfur, which improves machinability but slightly affects its corrosion resistance. This material balances machinability, strength, and moderate corrosion resistance, making it ideal for precision parts and components.

304 Stainless Steel Bar

304 Stainless Steel Bar is one of the most versatile and widely used austenitic stainless steel. It is known for its excellent combination of strength, corrosion resistance, and formability. 304 is used in various industries, such as automotive, aerospace, food processing, and construction. It is an alloy composed primarily of chromium and nickel, providing remarkable properties.

316 Stainless Steel Bar

316 Stainless Steel Bar is an austenitic stainless steel alloy. It offers better corrosion resistance than other 300 series stainless steels. This grade is highly regarded for its resistance to chlorides and harsh environments. It is ideal for use in marine, chemical, and industrial applications. Adding molybdenum to its composition enhances its corrosion resistance and durability, especially against pitting and crevice corrosion.

Stainless steel bars in different shapes

Round stainless steel bars are one of the most common types of stainless steel bars. They have a round cross-section and offer high strength and corrosion resistance. They are commonly used in machinery processing, construction structures, and equipment manufacturing.

Square stainless steel bars have a cross-section with four equal sides. They are mainly used in structures that need to bear high loads and are also commonly seen in decorative and construction applications.

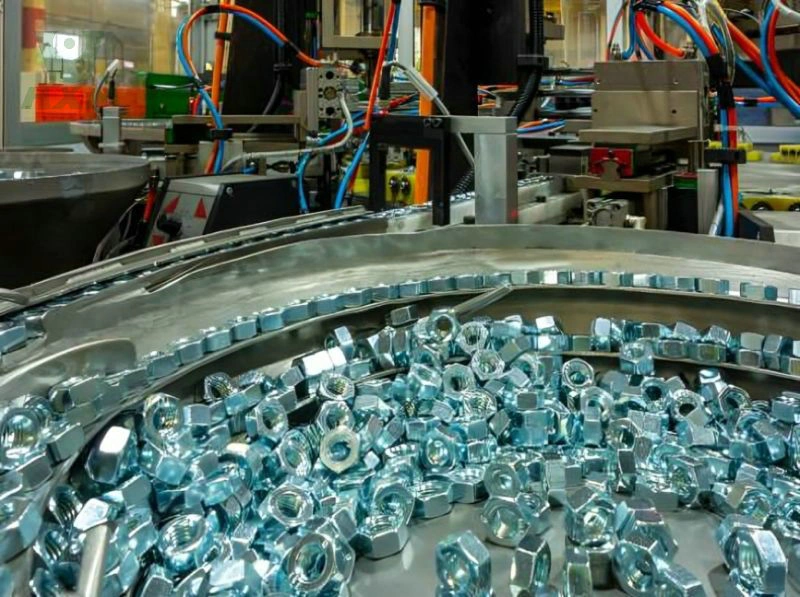

Hexagonal stainless steel bars have a hexagon-shaped cross-section and are often used to make bolts, nuts, and other fasteners.

Angle stainless steel bars have an L-shaped cross-section, making them suitable for structural support and reinforcement. Their design allows them to perform well under bending and tensile stress.

Stainless Steel Bars – Available Sizes

At HXSCO, we offer stainless steel bars in a variety of sizes to suit different applications. Whether you need round, square, hexagonal, or angle stainless steel bars, we provide options tailored to your project requirements.

- Round Bars: Diameters from 6 mm to 500 mm.

- Square Bars: Sizes from 10 mm x 10 mm to 200 mm x 200 mm.

- Hexagonal Bars: Across-flats from 10 mm to 100 mm.

- Angle Bars: Leg lengths from 20 mm x 20 mm to 200 mm x 200 mm, with various thicknesses.

Our stainless steel bars are manufactured to precise dimensional standards. This ensures high quality and reliability in industries such as construction, manufacturing and engineering. We can provide custom sizes to suit your specific requirements.

| Type | Size Range (Diameter / Across Flat) | Grades | Finish | Surface Finish | Heat Treatment | Straightness |

|---|---|---|---|---|---|---|

| Round Stainless Steel Bars | 1/16″ to 24″ | 304, 316, 303, etc. | Hot rolled, cold drawn, centerless ground | Bright, polished, rough turned | Annealed or solution annealed | Standard straightness tolerances |

| Square Stainless Steel Bars | 1/8″ to 6″ | 304, 316, etc. | Mill finish, polished | Bright, polished, rough turned | Annealed or solution annealed | Standard straightness tolerances |

| Hexagonal Stainless Steel Bars | 1/8″ to 3″ | 304, 316, etc. | Cold drawn, centerless ground | Bright, polished, rough turned | Annealed or solution annealed | Standard straightness tolerances |

Advantages of Stainless Steel Bars

Stainless steel bars are known for their exceptional qualities, making them indispensable in various industries and applications:

- Corrosion Resistance: Withstands harsh environments.

- High Tensile Strength: Suitable for heavy-duty applications.

- Durability: Long-lasting under demanding conditions.

- Heat Resistance: Performs well at high temperatures.

- Formability: Easy to shape and fabricate.

- Low Maintenance: Requires minimal upkeep.

- Aesthetic Appeal: Offers a sleek and modern look.

- Eco-Friendly: Fully recyclable and sustainable.

These features make stainless steel bars a reliable choice for manufacturing, construction, and engineering.

Applications of Stainless Steel Bars by Shape

Round Stainless Steel Bars

- Machinery Components: Used for shafts, spindles, and other rotating parts due to their uniform strength and machinability

- Fasteners: Ideal for manufacturing bolts, screws, and rivets

- Construction: Employed in reinforcement structures and architectural elements requiring high-strength

- Automotive: Common in drivetrain components like axles and connecting rods

Square Stainless Steel Bars

- Structural Supports: Used in construction frameworks for load-bearing stability

- Decorative Applications: Applied in fences, railings, and interior designs for their aesthetic appeal

- Manufacturing: Utilized for tools and die components requiring durability and precision

Hexagonal Stainless Steel Bars

- Fasteners: Widely used for nuts, bolts, and threaded components due to their multi-faceted design

- Tools: Commonly used in hand tools such as wrenches due to their ergonomic grip

- Industrial Equipment: Applied in mechanical assemblies requiring secure connections

Flat Stainless Steel Bars

- Structural Reinforcement: Used as braces, brackets, and supports in construction and engineering

- Fabrication: Employed in custom machinery, conveyor systems, and industrial equipment

- Electrical Components: Applied in bus bars for electrical conductivity and durability

- Decorative Features: Often used for architectural cladding and trim

Angle Stainless Steel Bars

- Structural Frameworks: Widely used in construction for reinforcing joints and frames

- Machinery: Applied as brackets and supports for heavy equipment

- Transportation: Used in manufacturing vehicle chassis and rail components

- Industrial Applications: Essential for creating racks, shelves, and platforms requiring rigidity and stability