China Aluminum profile supplier – aluminum extrusion manufacturing

HXSCO is a leading aluminum profile supplier and manufacturer in China. We specialize in aluminum profiles and extrusions. Our products meet diverse business needs.

What we offer:

- Custom Aluminum Profiles: We create specific designs for unique needs.

- OEM Aluminum Profiles: We supply aluminum profiles tailored for manufacturers.

- Aluminum Extrusion Services: We produce a variety of shapes and sizes.

- Aluminum Extrusion Fabrication: We turn extruded aluminum into finished products.

Our facility is among the most advanced in China, ensuring high-quality products. As a top supplier, HXSCO aluminum profile supplier can handle large orders with precision.

Our catalog includes a wide range of aluminum extrusions for different industries. We provide profiles for construction, transportation, and custom projects.

HXSCO aluminum extrusion manufacturer is dedicated to delivering durable and efficient aluminum solutions.

Contact Us| Alloy | Temper |

|---|---|

| 2xxx: 2017, 2024, 2017A | T6, T3, T651, T6511 |

| 6xxx: 6060, 6063, 6061, 6082 | |

| 7xxx: 7075 | |

| AVAILABLE SIZE RANGE |

|

| SURFACE FINISH | Bright Finish, Mill Finish, Anodized Color Finish |

Aluminum profile/extrusion specification

TYPES OF china aluminum extrusion

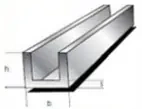

Rectangular aluminum profiles

- Rectangular aluminum profiles are widely used in construction, machinery manufacturing, and industrial equipment, especially for frame structures, support structures, and decorative elements. Their dimensional stability and ease of processing enable them to meet various complex design requirements.

- Width (B): Typically ranging from 10mm to 300mm/Height (H): Varies from 5mm to 150mm./Wall Thickness (T): Commonly between 0.5mm to 10mm.

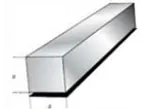

Square aluminum profiles

- Square aluminum profiles are widely used in construction, machinery manufacturing, furniture, and decoration, especially for frames, support structures, and modular designs. Their high stability and ease of processing enable them to meet various complex design requirements.

- Equal Width and Height (B = H): Usually ranging from 5mm to 150mm/Wall Thickness (T): Similar to rectangular profiles, ranging from 0.5mm to 10mm.

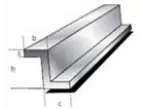

T-shaped aluminum profiles

- T-shaped aluminum profiles are widely used in construction, industrial manufacturing, and furniture assembly, especially for frame structures, connectors, and support systems. The high stability and easy processing of T-shaped aluminum profiles enable them to adapt to various complex design requirements flexibly.

- Width of the Top Flange (B1): Commonly between 10mm to 200mm/Width of the Vertical Web (B2): Similar range as the top flange/Height of the Vertical Web (H): Typically ranging from 5mm to 100mm/Wall Thickness (T): 0.5mm to 8mm.

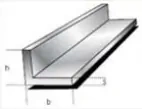

L-shaped aluminum profile (angle profile)

- L-shaped aluminum profiles are widely used in construction, machinery manufacturing, and furniture and are particularly suitable for angle support, frame structure, and edge protection. Their high stability and ease of processing allow them to meet various complex design requirements.

- Leg Length (L1, L2): Commonly between 10mm to 150mm/Thickness (T): Varies from 1mm to 10mm.

I-shaped aluminum profiles

- I-shaped aluminum profiles have excellent bending and torsion resistance, making them widely used in buildings, bridges, machinery, and industrial equipment. Their lightweight, high strength, and easy processing make them ideal choices for various large structures and engineering projects, which can effectively improve the safety and durability of the structure.

Processing Services of aluminum extrusion company – HXSCO

HXSCO, a leading aluminum extrusion company in China, provides comprehensive aluminum profile services.

Processing Services:

- Cutting: We offer both straight line and angle/miter cuts for single items or large orders. Our cutting capability reaches up to a 16-inch (406 mm) diameter.

- Finishing: This service includes clear, color, and hard anodizing. Not only this, but HXSCO also helps in paint, powder coat, polish, and foil. Our specialists also apply protective coatings and sleeves to protect products during transit.

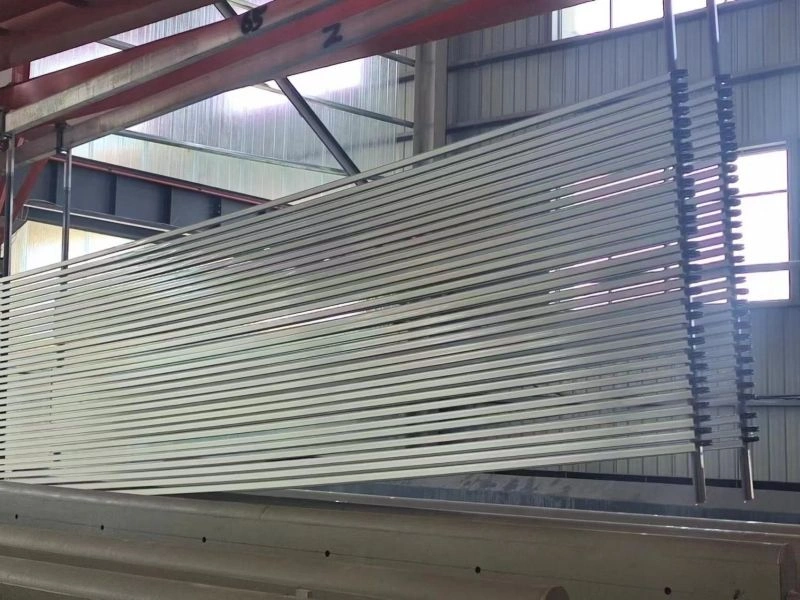

- Packaging: We use pallets, stillages, cages, and crates for packaging. Our methods ensure safe transit and handling, including options like interleaving or sleeving.

- Prefabrication: Our capabilities include drilling, notching, slotting, punching, and bending. You can also get the machining (turning, routing, milling) and threading. We also perform laser and water-jet cutting to produce ready-to-use parts.

- Thermal Breaking: We apply thermal breaking using a polyimide insulation strip. The cut-and-fill method is also used to enhance thermal performance.

HXSCO is committed to delivering precision-engineered aluminum solutions for various industrial needs.

What is anodised aluminium

Anodized aluminum is a particular type of aluminum that undergoes an electrochemical process. This treatment enhances its properties. Here’s a breakdown of the process and its benefits:

The Anodising Process:

- Preparation: Aluminium is first cleaned to remove impurities.

- Electrolytic Bath: The clean aluminum goes into an acid bath, typically sulfuric acid.

- Electrical Current: A current is applied, turning the aluminum into an anode.

- Oxide Layer Formation: The current makes oxygen ions react with the aluminum surface. As a result of this reaction, a durable aluminum oxide layer is created.

- Sealing: The oxide layer is sealed in hot water or steam to close its pores.

Benefits of Anodised Aluminium:

- Increased Durability: The new layer is much stronger than plain aluminum. Therefore, it resists scratches excellently.

- Corrosion Resistance: The oxide layer shields the aluminum from rust. This protective layer also protects the aluminum from extreme environmental conditions.

- Aesthetic Enhancements: The metal can be dyed before sealing to add color. Or, it can be left metallic for a shiny finish.

- Improved Adhesion: Paints and glues stick better to the rough anodized surface.

- Electrical Insulation: Anodised aluminum does not conduct electricity, which is helpful in electronics.

Anodized aluminum is popular in aerospace, automotive, construction, and electronics. The reason is that this material is very durable and robust.

custom aluminum extrusion and profile

Advantages of wholesale aluminum extrusion

Lightweight and Strong

Aluminum offers an excellent strength-to-weight ratio. This ratio is essential for industries like automotive, aerospace, and construction. It provides necessary strength while being lighter than many other metals.

Non-Corrosive

Aluminum naturally forms a protective oxide coating known as aluminum oxide. This coating makes it highly resistant to corrosion. This feature ensures that aluminum extrusions can endure harsh environments without deteriorating. Due to this, it’s considered suitable for outdoor and marine uses.

Recyclable

Aluminum is 100% recyclable and maintains its properties after recycling. This attribute supports environmental sustainability. In this way, it reduces carbon footprint in manufacturing processes.

Resilient and Hard-Wearing

Aluminum extrusions are robust. They can easily withstand significant stress without deforming. They are also resistant to wear and tear, which ensures longevity. So, there will be minimal need for frequent replacements.

Common uses for aluminum extrusion and profile

Building and Construction

Aluminum extrusions are used to construct many products. Those include window frames, door frames, roofing, and curtain wall systems. They offer durability and strength. Above all, they meet aesthetic requirements for modern architecture due to their sleek finish.

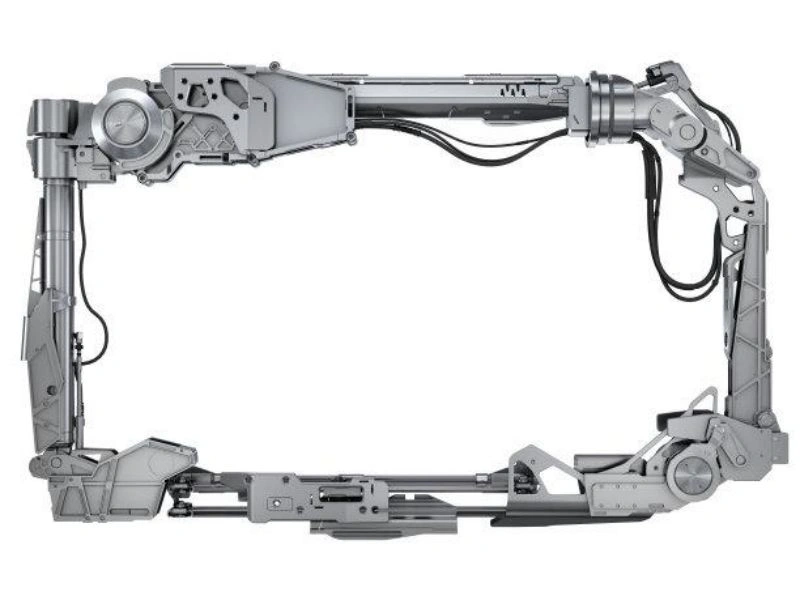

Automotive and Transportation

The automotive industry uses aluminum profiles. They help make parts that contribute to lightweight vehicle construction. This improves fuel efficiency and reduces emissions. Typical applications include frame structures, radiator enclosures, and body panels.

.

Electronics

Aluminum has excellent heat dissipation properties. These properties make it ideal for use in electronic goods. It is used in cases and frames for computers and televisions. It is also used in heat sinks that protect sensitive parts and in LED lighting fixtures.

Aerospace

The aerospace industry values aluminum extrusions for their high strength-to-weight ratio. They are used in the manufacture of many parts and components of aircraft. Those include airframes, fuselage structures, and wing tension members of aircraft.

Industrial Machinery

Aluminum extrusions are used in machinery and equipment. Those include conveyor systems, automation structures, and frames for machinery. This is due to the resilience and ability of aluminum to withstand high temperatures.

Energy Sector

The energy sector uses aluminum extrusions in solar panels and wind turbines. They also make frames and housing that are exposed to the elements. They benefit from aluminum’s rust resistance and remain in good shape for long.

QUALITY ALUMINIUM EXTRUSIONS AND SERVICES

Aluminum profile delivery pictures