china aluminum diamond/checker plate manufacturer

The aluminum checker plate is also known as an aluminum diamond plate or aluminum tread plate. It is essentially an aluminum plate with a raised, non-slip pattern. This decorative pattern enhances its structural integrity, making it ideal for toolboxes, freight, emergency vehicles, and construction. These plates are durable and versatile and available in grades such as 3003, 5052, 5086, and 6061.

As a leading plate supplier in China, we offer high-quality custom aluminum tread plates tailored to B2B needs. Our products, including China aluminum diamond plates and wholesale aluminum diamond plates, ensure outstanding performance and satisfaction. HXSCO is one of the leading manufacturers of aluminum tread plates.

Specifications of Aluminum Diamond Plate

| Property | Details |

|---|---|

| Material | High-grade aluminum checker sheet |

| Finish | Mill and polish |

| Thickness | 0.1″, 0.63″, 0.125″, 0.188″, 0.250″, 0.45″, 0.5″ |

| Panel size | Max. 4′ × 10′ (usually is 1′ × 1′, 1′ × 2′, 1′ × 4′, 1′ × 8′, 2′ × 2′, 2′ × 4′, 2′ × 8′, 4′ × 4′, 4′ × 8′) |

| Color | Silver, black |

| Standards |

|

| Alloy | 1000 series, 2000 series, 3000 series, 5000 series, 6000 series, 7000 |

| Temper | O, H22, H24, H26, H32, H34 |

| Pattern Type | Small Five Bar, Big Five Bar, Diamond, Two Bar, Three Bar |

Types of Aluminum Checker Plates by Pattern

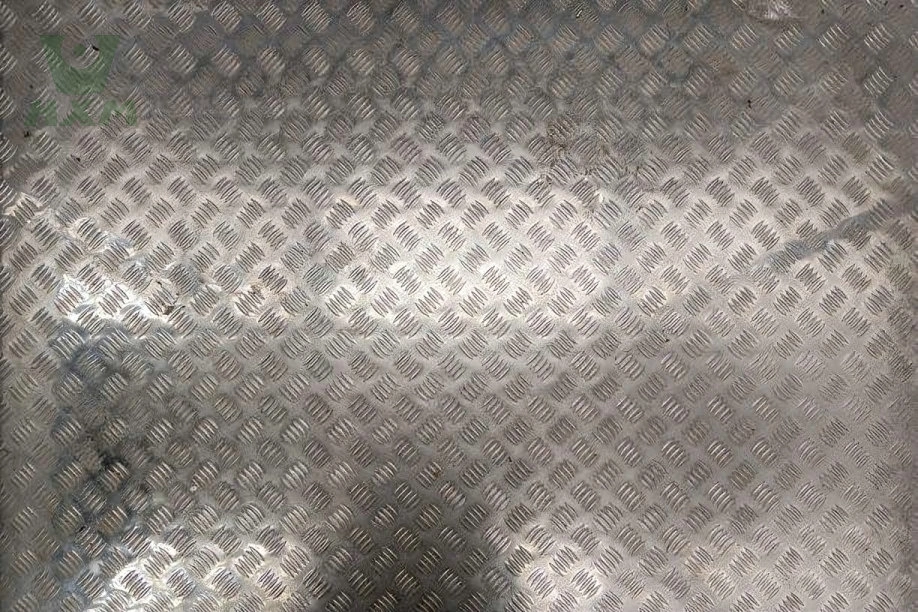

Diamond Checker Plate (One-Bar Checker Plate)

- Description: The most commonly recognized aluminum checker plate features a single diamond-shaped pattern that runs diagonally across the surface.

- Applications: It’s ideal for industrial floors, stair treads, and platforms where slip resistance is crucial. Due to its distinctive pattern, it’s also popular in decorative applications.

Five-Bar Checker Plate

- Description: This type features five parallel bars arranged in alternating directions, creating a crisscross pattern. Known for offering superior traction, it’s sometimes called a “Quintet” or “Five-Rib” plate.

- Applications: It is preferred in areas requiring maximum grip, such as vehicle steps, loading docks, and ramps. It’s also widely used in walkways and flooring for heavy-duty industrial settings.

Two-Bar Checker Plate

- Description: This plate has two raised bars running parallel to each other, providing a moderate level of grip. It’s sometimes called a “Duet” or “Double-Bar” checker plate.

- Applications: It is suitable for lighter-duty applications where some slip resistance is needed, such as toolboxes, storage units, and interior vehicle floors.

Three-Bar Checker Plate

- Description: Featuring three raised bars in a linear pattern, this type balances grip and ease of cleaning. It’s known as a “Trio” checker plate in some industries.

- Applications: Commonly used in environments where moderate traction is required, including kitchen floors, workshop areas, and low-traffic walkways.

Pointer (Propeller) Checker Plate

- Description: This checker plate has a unique, decorative pattern resembling a propeller or teardrop. It is often chosen more for its aesthetic appeal than for functionality.

- Applications: Popular in architectural projects, interior design, and automotive applications where visual impact is important alongside slip resistance.

process for manufacturing aluminum checker plate

Raw material preparation

Aluminum alloy plate: We usually use alloys with high aluminum content, such as 1050, 1060, 3003, or 5052. Choosing the right alloy ensures the strength and corrosion resistance of the final product.

Melting and casting

Melting: We heat the aluminum alloy in a furnace until it becomes liquid.

Casting: Workers pour the molten aluminum into a mold to form an ingot for further processing.

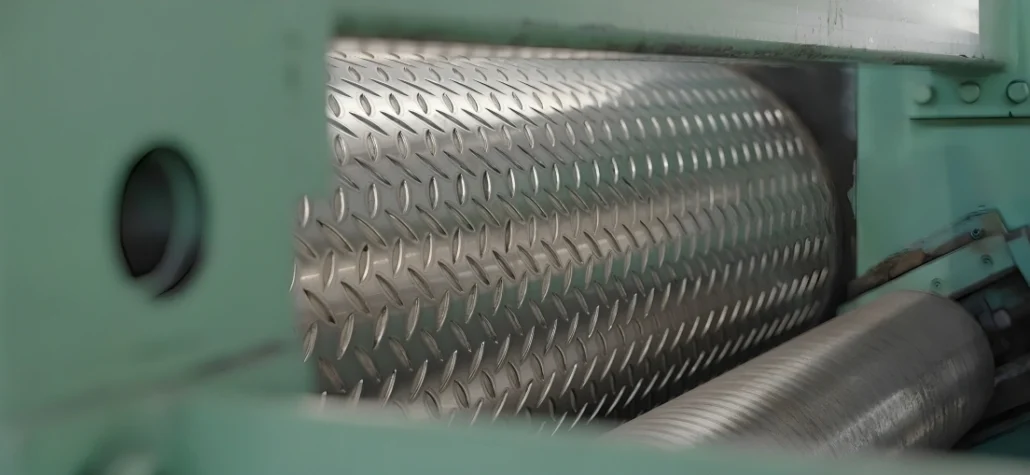

Rolling

- Hot rolling: Workers heat the aluminum ingot to the right temperature. Then pass through a hot rolling mill to reduce thickness and improve flatness.

- Cold rolling: The mature Diamond Checker Plate supplier cools the hot-rolled aluminum plate to room temperature. Then pass through a cold rolling mill to achieve the desired final thickness and surface smoothness.

Pattern embossing

Mold selection: Choose the right embossing mold. Common patterns of aluminum checker plates include diamonds, dots, and linear designs.

Embossing: We put the cold-rolled aluminum plate into the embossing machine. Then, we apply pressure to emboss the pattern onto the surface. Depending on the design requirements, workers can use single-sided or double-sided molds to complete the process.

Cutting and forming

Cutting: Cut the embossed aluminum sheet into the required size.

Forming: To meet specific application needs, we can use other forming processes, such as bending or stamping.

Surface Treatment of aluminum diamond/checker plate

Cleaning: Clean the surface of the aluminum checker plate to remove any dirt and residues from the manufacturing process.

Coating: Upon request, we can anodize or paint the checkered plate to enhance corrosion resistance and appearance.

Advantages of Aluminum Checker Plate

Lightweight: Aluminum checker plates are much lighter than many other metal materials. They are also easier to handle and install, reducing transportation costs.

Anti-slip performance: The embossed pattern on the checker plate provides excellent traction. It is ideal for floors and surfaces that need to be slip-resistant.

Aesthetics: Aluminum checker plates have a unique patterned surface that is aesthetically pleasing. They can enhance the appearance of a variety of applications.

Durability: Aluminum is naturally resistant to corrosion and wear. Checker plates are durable and can withstand harsh environmental conditions.

Easy processing: The aluminum checker plate is easy to cut, bend, and process, allowing for easy fabrication and customization of various applications.

Recyclability: Aluminum is 100% recyclable without sacrificing quality. Aluminum checker plate is an ideal choice for environmental protection.

Easy assembly: The Aluminum Checker Plate is lightweight and easy to handle. It is very simple to assemble and install in a variety of environments.

Custom Options for Aluminum Checker Plates

Size

- Length and Width: HXSCO, an aluminum checker plate manufacturer, offers aluminum plates in commonly used standard sizes. However, you can also choose custom sizes to meet specific project requirements.

- Plate Size: We usually offer standard plate sizes, such as 4×8 feet or 1×2 meters. But we can also produce custom sizes.

Thickness

- Aluminum checker plates are available in a variety of thicknesses, usually from 1 mm to 6 mm or more. You can also order custom thicknesses based on your application needs.

Finish

- Anodizing: Enhances corrosion resistance and improves appearance with a variety of finishes.

- Powder Coating: Adds a protective layer and is available in a variety of colors and finishes.

- Rolled Finish: Natural, uncoated finish, often used for its industrial look.

- Brushed Finish: A smooth brushed surface enhances beauty and reduces glare.

Colors

- Standard Colors: Usually available in natural aluminum, silver, and sometimes black.

- Custom Colors: Red, gray, blue, and other color options are available through powder coating or anodizing. Based on project specifications, custom color requirements can be met.

Applications of Aluminum Checker Plates

Stair Treads and Walkways: Stairs, ramps, and walkways to prevent slips. Especially in outdoor or wet environments.

Automotive: Anti-slip surfaces in trucks, trailers, and other vehicles. Enable safer loading, unloading, and movement.

Marine Applications: Stable anti-slip surfaces in vessels, ships, and offshore platforms exposed to water.

Mining: Equipment, machinery platforms, and work areas. Reduce slip hazards and ensure safe mining operations.

Elevators: Anti-slip floor surfaces improve safety in elevators.

Industrial Flooring: Anti-slip surfaces in factories, warehouses, and manufacturing facilities. Enhance safety in high-traffic areas.

Aluminum checker plate delivery pictures