Understanding Alloy Steel Bar

In the dynamic landscape of metallurgy, Alloy Steel Bar emerge as stalwart components, offering a blend of strength, resilience, and versatility. As a premier Alloy Steel supplier based in the bustling hub of Shanghai, China, HXSCO takes pride in unraveling the intricacies of Alloy Steel Bar, setting the stage for a profound exploration into their definition, composition, and distinctive properties.

Definition and Composition of Alloy Steel Bar

At its essence, an Alloy Steel Bar is a solid, long product crafted from a mixture of iron and various alloying elements. These alloying elements, such as chromium, nickel, manganese, and molybdenum, transcend the conventional constraints of carbon steel, infusing the bars with enhanced properties. Alloy Steel Bar are meticulously engineered to meet stringent industry standards, ensuring a superior amalgamation of strength and durability.

HXSCO, among the leading Alloy Steel suppliers globally, prides itself on providing a diverse range of Alloy Steel Bar, each tailored to meet the unique demands of discerning industries. Our Alloy Steel Bar undergo a meticulous alloying process, where precision meets innovation, resulting in products that redefine industry benchmarks.

Key Properties that Make Alloy Steel Bar Stand Out

What sets Alloy Steel Bar apart in the spectrum of steel products are their remarkable properties. These bars boast exceptional strength, making them ideal for applications demanding resilience under varying conditions. With a high tensile strength and robust resistance to wear and tear, Alloy Steel Bar offer a prolonged service life, making them an investment in longevity.

The versatility of Alloy Steel Bar is underscored by their ability to withstand extreme temperatures, making them invaluable in applications ranging from construction to manufacturing. Whether it’s providing structural support in buildings or facilitating the production of intricate machinery components, Alloy Steel Bar play a pivotal role in diverse industrial landscapes.

As Alloy Steel suppliers committed to excellence, HXSCO ensures that our Alloy Steel Bar not only meet but exceed industry expectations. Through a stringent quality control process, we guarantee bars that not only adhere to international standards but also elevate the performance standards of the industries they serve.

Different Alloying Elements

4140 Alloy Steel

4340 alloy steel

8620 Alloy Steel

52100 Alloy Steel

6150 alloy steel

6150 alloy steel

52100VM alloy steel

9310 alloy steel

Their Impact On Alloy Steel Bar Performance

In the intricate alchemy of metallurgy, the prowess of Alloy Steel Bar is not merely a consequence of their base components, but rather a symphony orchestrated by the infusion of various alloying elements. As esteemed Alloy Steel suppliers, HXSCO is dedicated to unraveling the nuanced impact these elements have on the performance and versatility of Alloy Steel Bar.

Chromium

One of the stalwart alloying elements in Alloy Steel Bar is chromium, recognized for its role in enhancing corrosion resistance. As Alloy Steel suppliers committed to providing materials resilient to the harshest environments, HXSCO ensures that our Alloy Steel Bar, enriched with chromium, exhibit an unparalleled resistance to corrosion, making them indispensable in applications exposed to moisture, chemicals, and varying climatic conditions.

Manganese

Manganese, a robust austenite-forming element, is a linchpin in the metallurgical formula of Alloy Steel Bar. The presence of manganese contributes to the bars’ strength, ductility, and wear resistance. Alloy Steel suppliers at HXSCO meticulously calibrate the manganese content in our bars, ensuring that they strike the perfect balance between formability and durability, catering to a spectrum of industrial applications.

Nickel

Nickel, a versatile alloying element, imparts Alloy Steel Bar with a multifaceted set of properties. Beyond elevating the bars’ corrosion resistance, nickel augments their toughness, facilitating applications in extreme temperatures. Alloy Steel suppliers like HXSCO recognize the significance of nickel in crafting bars that not only withstand the rigors of industrial operations but also exhibit a remarkable adaptability to diverse working conditions.

Molybdenum

For Alloy Steel Bar destined for environments characterized by high temperatures and stress, molybdenum emerges as a critical alloying element. HXSCO, as discerning Alloy Steel suppliers, integrates molybdenum strategically into our bars to bolster their thermal stability and mechanical strength. The result is a product that excels in demanding applications, from aerospace components to energy infrastructure.

Vanadium

Vanadium, a lesser-known yet potent alloying element, imparts Alloy Steel Bar with heightened strength and wear resistance. Recognizing the evolving needs of industries, Alloy Steel suppliers at HXSCO harness the benefits of vanadium to engineer bars that not only meet but surpass the stringent requirements of modern applications, from construction to machinery manufacturing.

As we navigate the complex landscape of alloying elements, it becomes evident that the mettle of Alloy Steel Bar lies in the meticulous orchestration of these components. Alloy Steel suppliers like HXSCO play a pivotal role in not only providing these bars but also in ensuring that they are tailored to meet the specific demands of diverse industries.

Applications And Industries Served

In the ever-evolving landscape of industrial applications, Alloy Steel Bar emerge as versatile workhorses, seamlessly integrating into a myriad of industries. As paramount Alloy Steel suppliers, HXSCO takes pride in illuminating the diverse applications that harness the strength, resilience, and adaptability of Alloy Steel Bar.

Construction Industry

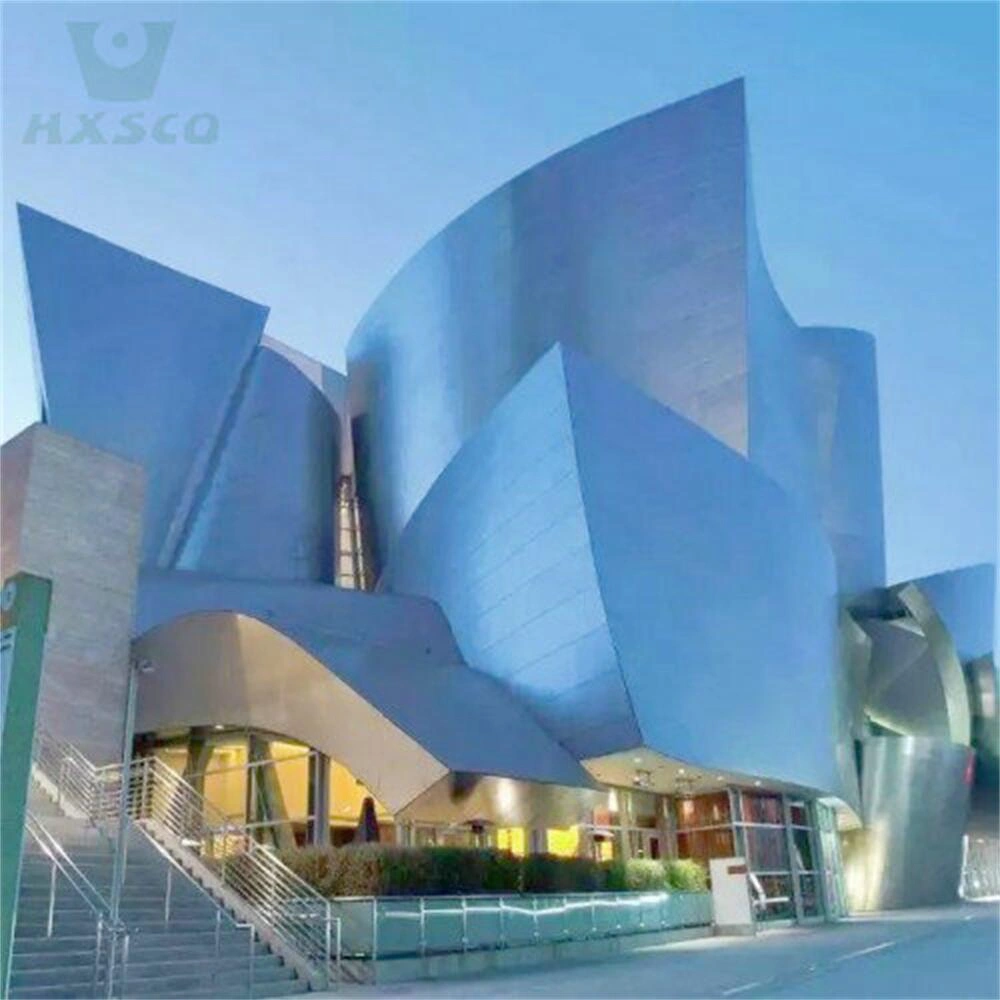

Alloy Steel Bar form the backbone of modern construction, reinforcing structures with their exceptional strength and ductility. From towering skyscrapers to intricate bridges, these bars ensure structural integrity and longevity, making them indispensable to architects and builders worldwide.

Automotive Sector

In the automotive realm, Alloy Steel Bar find their place in the intricate framework of chassis and suspension systems. The bars’ high tensile strength and fatigue resistance contribute to the durability and safety of vehicles, aligning seamlessly with the stringent standards of the automotive industry.

Energy Infrastructure

Alloy Steel Bar play a pivotal role in the energy sector, where their resistance to corrosion and extreme temperatures is harnessed for the construction of pipelines and power generation facilities. As Alloy Steel suppliers dedicated to sustainability, HXSCO contributes to the robustness and efficiency of global energy infrastructure.

Aerospace Engineering

The demands of aerospace engineering necessitate materials that can withstand rigorous conditions, and Alloy Steel Bar rise to the challenge. With strategic alloying elements, these bars deliver a perfect balance of strength and weight, making them essential components in aircraft construction.

Showcasing Success Stories

At HXSCO, our commitment to excellence as Alloy Steel suppliers is echoed in the success stories and case studies that underscore the real-world impact of Alloy Steel Bar.

Case Study 1: Structural Reinforcement in High-Rise Buildings

In a collaboration with a leading construction company, our Alloy Steel Bar were employed to reinforce the structural framework of a landmark high-rise building. The result was a structure that not only met but exceeded safety standards, showcasing the reliability and performance of Alloy Steel Bar in critical construction applications.

Case Study 2: Enhancing Automotive Safety

Working closely with an innovative automotive manufacturer, HXSCO supplied Alloy Steel Bar for the development of a groundbreaking safety system. The high-strength properties of the bars contributed to the creation of a robust and lightweight chassis, enhancing the overall safety profile of the vehicle.

Case Study 3: Optimizing Energy Infrastructure

In a large-scale energy infrastructure project, HXSCO played a pivotal role in supplying Alloy Steel Bar for the construction of pipelines. The corrosion-resistant properties of our bars ensured the longevity of the infrastructure, contributing to the sustainability and reliability of the energy network.

In conclusion, the applications of Alloy Steel Bar span across industries, each telling a unique story of strength, innovation, and reliability. As dedicated Alloy Steel suppliers, HXSCO continues to be at the forefront of supplying bars that not only meet but exceed the diverse needs of industries worldwide.

HXSCO’s Commitment To Quality

In the dynamic realm of Alloy Steel Bar supply, HXSCO stands as an unwavering beacon of reliability and quality. As a dedicated B2B supplier based in Shanghai, China, our commitment extends far beyond delivering Alloy Steel Bars; it encompasses a steadfast pledge to excellence, innovation, and client satisfaction.

Reliable B2B Supplier for Alloy Steel Bar

HXSCO’s role as a reliable B2B supplier for Alloy Steel Bar is anchored in a foundation of trust and transparency. For years, we have been the go-to source for global industries seeking top-tier Alloy Steel products. Our comprehensive inventory, coupled with a seamless supply chain, ensures that our clients receive Alloy Steel Bar that align precisely with their specifications and exceed industry standards.

As Alloy Steel suppliers, we understand the critical role these bars play in the success of our clients’ projects. Whether it’s fortifying a skyscraper’s structural framework or contributing to the efficiency of an energy plant, HXSCO’s Alloy Steel Bar are engineered to deliver unparalleled performance in every application.

Stringent Quality Control Measures

At HXSCO, quality is not a mere attribute; it is a commitment woven into the fabric of our operations. Our Alloy Steel Bar undergo rigorous quality control measures to guarantee that each product leaving our facilities is a testament to precision and durability.

1. Metallurgical Expertise:

Our team of seasoned metallurgists employs cutting-edge techniques to monitor and optimize the alloying process. This meticulous approach ensures that Alloy Steel Bar produced by HXSCO possess the desired mechanical properties, from strength and toughness to corrosion resistance.

2. State-of-the-Art Testing Facilities:

Quality assurance is non-negotiable at HXSCO. Our state-of-the-art testing facilities conduct thorough inspections, including hardness testing, tensile testing, and impact testing, to validate the integrity of every Alloy Steel Bar. This commitment to precision ensures that our clients receive products that meet and exceed their expectations.

3. Traceability and Documentation:

HXSCO recognizes the importance of traceability in the supply chain. Our Alloy Steel Bar come with comprehensive documentation, detailing the alloy composition, manufacturing processes, and quality test results. This transparency provides our clients with the confidence that they are receiving Alloy Steel Bar of the highest caliber.

As Alloy Steel suppliers, our commitment to quality is not just a promise; it is a practice embedded in every step of our operations. HXSCO takes pride in being a trusted partner for industries seeking Alloy Steel Bar that stand up to the most demanding conditions.

Our commitment to quality extends beyond the products themselves; it encompasses a client-centric approach that prioritizes communication, customization, and continuous improvement. HXSCO collaborates closely with clients to understand their unique Alloy Steel Bar requirements, offering tailored solutions that align with their project goals.

In conclusion, HXSCO’s role as a reliable B2B supplier for Alloy Steel Bar is a testament to our dedication to quality, precision, and client satisfaction.

Conclusion

As we draw the curtains on this exploration of Alloy Steel Bar, it becomes evident that these stalwart components are more than mere industrial assets; they are the backbone of progress and innovation. At HXSCO, we take immense pride in our role as Alloy Steel suppliers, dedicated to delivering not just bars but a commitment to excellence that resonates across industries globally.

Choosing HXSCO for your Alloy Steel Bar needs means embracing a partnership that transcends the transactional. It signifies a commitment to precision, quality, and a client-centric approach that tailors solutions to your unique project requirements.

Our Alloy Steel Bar, meticulously crafted with an infusion of alloying elements, embody the resilience and strength required for the most demanding applications. From construction marvels that shape skylines to aerospace innovations that defy gravity, our bars play an integral role in the tapestry of modern advancements.

In the realm of Alloy Steel suppliers, HXSCO stands tall as a beacon of reliability, offering not just a product but a comprehensive solution that aligns with the intricacies of your project. Our competitive pricing, transparency in business practices, and commitment to customization ensure that your Alloy Steel Bar procurement is not just efficient but optimized for success.

As you navigate the complex landscape of industrial projects, let HXSCO be your trusted partner, providing Alloy Steel Bar that exceed expectations and contribute to the longevity and success of your endeavors. Our global reach and efficient export services underscore our commitment to being not just a supplier but a strategic ally in your journey towards excellence.

Thank you for embarking on this journey with us, exploring the nuances and possibilities that Alloy Steel Bar bring to the forefront. At HXSCO, we look forward to continuing our shared exploration of metallurgical mastery, innovation, and the enduring impact of Alloy Steel Bar on the industries that propel our world forward.