Stainless steel, the most used alloy, is well known for its durability and fine surface. But have you ever wondered what enhances its shine and durability? Thanks to the finishing procedure that makes it so. However, there are several stainless steel finishing options. All those options give you different types of surface appearance.

They vary due to their texture, durability, and formation. Choosing the right one that matches your desire is very crucial. Are you confused about those finishing options? Fret not! In this article, I will discuss them in detail. Moreover, this guide will also make their selection easy for you. So, let’s get started!

What is stainless steel finishing?

Finishing is the process of giving a new appearance to the metals. Stainless steel also gets a shiny surface through this process. It is not a straightforward process but includes a series of steps. Those steps involve polishing, brushing, and blasting. Some advanced types of finishing also involve the step of electrochemical treatment.

The finishing process is very advantageous. It gives a shiny surface and saves the metal from corrosion. As you know, stainless steel is made of iron, chromium, and nickel. So, naturally, it is resistant to corrosion due to the presence of chromium. However, in some harsh conditions, chromium fails to save it.

Thus, for extra safety, finishes are applied to the surface of the stainless steel. There are several types of stainless steel finishing. For example, mirror finish, 2D finish, and 2B matte finish. All these types give a different appearance to stainless steel. Moreover, these finishes are also used for various purposes.

Options for stainless steel finishing

You have an idea of the finishing process from the above section, right? In the section below, we will explore several options for stainless steel finishing. Remember that all these options have different qualities and functional benefits. So, for better results, follow each option’s specifications carefully.

1- No. 1 Stainless Steel Finish

No.1 finishing gives stainless steel a rough appearance. However, this rough surface increases its durability. Therefore, this fishing option is more reliable where durability is a significant concern than delicate appearance. But, the question arises of how stainless steel gets the No.1 finishing. Basically, this is the hot hot-rolling procedure.

During this procedure, stainless steel is passed through intensive heat and pressure. Approximately the temperature during hot rolling is kept up to 900°C. Under such heat, the surface of the stainless steel becomes very dull. After hot rolling, the second step is to give the stainless steel durability.

Here, the annealing process comes into the scene. This is the process of cooling down the hot metal in a controlled way. Through this process, the internal structure of the stainless steel becomes very hard. It becomes less brittle and more ductile. After that, the third and last step takes of pickling takes place.

As I said above, the stainless steel structure becomes rough during hot rolling. Several layers appear on its surface. The pickling process removes these layers. This process occurs by keeping the stainless steel in an acid bath for some time. The acid effectively removes the impurities in the form of these layers.

Quick Highlight: Remember that the pickling process does not give a fine finish. It only removes the impurities. If you are looking for a fine surface of stainless steel, then No.1 finishing is not your go-to option.

2- No. 3 Stainless Steel Surface Finish

No.3 gives a fine structure to the stainless steel to some extent. It creates a less rough surface than the No.1 finish. This finishing option uses coarse abrasives. Coarse abrasives are the materials used in grinding, sanding, and polishing. These abrasives have different sizes and are used for various purposes.

Sandpaper and grinding wheels are typical examples of these abrasives. These abrasives remove imperfections and scales from the surface of stainless steel. Then, other abrasives are used to give polished surfaces. So, this type of finishing is moderate and provides reflectivity to some extent.

Therefore, these are used in electrical appliances and kitchen wares. You can also use this type of finishing for architectural purposes. Because it provides both durability and a good appearance. What I like about this type of finishing is its cost-effectiveness. The reason is that its creation process is very straightforward.

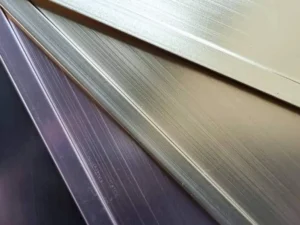

3- No. 4 Brushed Stainless Steel Finish

This type of finish is finer and shiny, providing a reflective surface to stainless steel. Like the No.3 finish, it also uses coarse abrasives. However, the abrasive used in this type is finer and creates grain on the surface of stainless steel. These grains give it a brushed-like appearance.

Moreover, the design of those grains is very uniform due to their single direction. This increases the aesthetics and smoothness of stainless steel. So, the cleaning process of stainless steel with this finish also becomes effortless. I highly recommend this finish if you want visual appeal and functionality simultaneously.

It is primarily used in architectural design, medical appliances, and furniture. However, this fishing option also has some drawbacks. For example, it does not provide a high degree of reflection. Moreover, a minor scratch diminishes the surface’s appearance. It requires re-polishing, which can cost more.

4- No. 6 Stainless Steel Surface Finish

This type of finishing is also known as “dull polish.” It has the lowest level of reflection among all types. WHY? This is due to its creation process. In the first step of this finishing, abrasives are used to remove imperfections. This process gives a fine structure and some reflectivity.

However, this reflectivity diminishes in the next step, Tampico brushing. In this process, an abrasive paste, which is dense and easy to use, is applied. This paste gives a matte finish, which dims the reflective appearance. Ultimately, it is dipped into some chemicals, increasing its matte appearance.

It is best suited if you are after corrosion resistance and a matte appearance. But if you are finding a reflective surface, you should not go for it. This finishing type is mainly used in commercial and retail spaces and furniture. Moreover, the cost of this finishing option is also moderate. So, it can be cost-effective if you have a tight budget.

5- No. 8 Mirror Finish on Stainless Steel

As suggested by the name, this type of finish gives a mirror-like appearance to stainless steel. It provides the highest level of reflectivity to the surface of stainless steel. But how is this finishing applied? It is a very straightforward process. In the first step, the surface of stainless steel is prepared by removing visible scratches.

After that, fine abrasives are used to smooth the surface. The abrasive paste is applied to give a shiny surface. Still, it is not a mirror-like surface. So, another process of final buffing takes place. In this process, high-speed buffing wheels are used. These wheels move with high speed on the surface of the steel and remove micro scratches.

The repetition of this process finally makes the surface shiny and smooth. No scratches or imperfections are left behind; the surface is like a mirror. This type of finishing is used in luxurious items, medical equipment, and modern automobiles. However, remember that such a highly reflective surface needs attention when used.

For example, fingerprints and scratches are visible on this surface. So, it requires proper maintenance with time. Moreover, the price of this finish can also shock your wallet. The reason lies in its creation process and a higher level of smoothness.

6- No. 2B Matte Finish for Stainless Steel

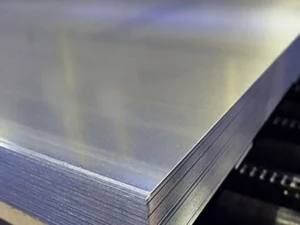

Another option for stainless steel finishing is the No.2B matte finish. This finish type gives a matte appearance to the surface of the stainless steel. So, the reflectivity in this finish is very low or zero. Again, the reason is its creation process. Let me explain its creation process simply. First, the cold rolling process takes place.

In this step, stainless steel passes through a roller at room temperature. This step makes the surface of stainless steel smooth and even. After that, the second step of annealing takes place. The cold-rolled steel is now heated in a controlled manner and becomes soft. The pressure created in cold rolling is also released in this step.

The surface becomes less brittle and more corrosion-resistant. After annealing, the pickling process starts. This step removes the contamination produced during the whole process. Now, the final process of “skin pass” begins. It involves cold rolling for a second time to ensure an ultimate fine surface.

The new surface formed by this finishing process is matte and non-reflective. Moreover, its cleanability is also effortless. The chances of scratches and fingerprints are less, which maintains the surface for a long time. So, this type of finishing is used in electronics and industrial equipment. Lastly, No.2B finishing is a cost-friendly option in terms of prices.

7- No. 2D Surface Finish for Stainless Steel

No.2D surface finish for stainless steel also provides a matte appearance. The steps involved in its creation are similar to No.2B. For example, the first step is cold rolling stainless steel at room temperature. The second step involves the annealing process in which heat softens stainless steel.

The final and last step is pickling. In this step, the oxide layers are removed using acid. So, what is the difference between a 2D and 2B matte finish? The main difference lies in the last step. Unlike the 2B finish, the 2D surface finish does not involve a “skin pass.” Therefore, the 2D surface finish is dull and less reflective than 2B.

However, the level of smoothness is almost equal to 2B. Moreover, the corrosion-resistant ability is also prominent in this finishing. It is also a cost-effective option if we talk about its prices. In fact, it is cheaper than 2B and all other finishes. This type of finishing is used in heat exchangers, pipes, and structural components.

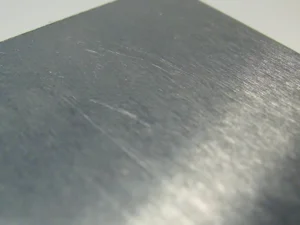

8- Bead Blasted Finish

This is a very interesting type of stainless steel finishing. Unlike other types, it uses an advanced technique called bead blasting. Are you unaware of this technique? Worry not! I will thoroughly explain it. Before applying this finish, the surface of the stainless steel is cleaned thoroughly.

After cleaning the surface, bead blasting starts. In this process, small particles made of ceramic or glass are bombarded on the surface at high speed. These particles make the surface of stainless steel even by creating micro-pits. These pits make the surface less reflective and matte but smooth.

You can control the speed of bombardment and the size of the beads according to your desire. In the end, the surface is cleaned. Removing the remaining particles or debris from the surface is crucial to making it finer. However, this finishing is comparatively costly and used in sculptural elevators and escalators.

9- Electropolished Finish

Electropolished finishing is the most advanced type of stainless steel finishing. It creates a glossy, smooth, mirror-like appearance. Its creation process uses electrolytes, which makes it so advanced. The stainless steel is dipped into a tub containing an electrolyte electrode.

The electrolytes are mainly sulfuric acid and phosphorous acid. The two electrodes (Anod and Cathod) are also connected. This setup dissolves the upper rough layer of stainless steel. By removing this layer, imperfections, and scratches are also removed. After that, the process of passivation begins.

This is the process of forming an oxide layer. HOW? The stainless steel is treated with nitric acid or citric acid. These acids remove the free iron, which is prone to corrosion. Removing the iron makes it easy for acid to react with chromium content from the oxide layer. This layer acts as a shield that protects the stainless steel from corrosion and rusting.

This is the reason that this type of finishing is versatile and costly. The level of reflectivity is also higher in this finishing. Therefore, it requires more maintenance and cleanability. As this finishing is with enhanced hygiene, you can use it in food processing equipment. The medical industries also use this type of finishing for better sanitation.

10- Etched Finish

Etched finishing is a unique type of stainless steel finishing. This type creates intricate patterns and designs on the surface. Not only this, but it also makes the surface finer, shiny, and visually appealing. Its creation procedure involves chemical etching. This process starts by cleaning the surface of the stainless steel.

It is vital to clean the surface to ensure the proper chemical etching process. If you want to protect some areas from chemical etching, apply etch resists. After that, the main procedure of chemical etching begins. This process uses acids such as hydrochloric or ferric chloride.

When stainless steel is dipped into an acid bath, the upper layer is removed, and the design is created. You can adjust the depth of etching by altering the concentration of acid. After this process is completed, stainless steel goes through the cleaning process. The final smooth, designed surface is obtained after this finishing.

If you are looking for customizability, it is the best option. In terms of price, it is the most costly of all types. However, its creation process, smoothness, durability, and shine justify its cost. It is used in architectural elements, jewelry, and art.

Choosing the Right Finish

There are several finishing options for stainless steel. But which is suitable for you? This is a very confusing question. But don’t worry! In the section below, I will discuss some considerations to help you choose the best one.

- First of all, understand your environmental conditions. Either it is humid or dry. Electropolished is the right option for using stainless steel in humid conditions.

- If your primary concern is durability, a No.4 finish is suitable. However, this finish does not possess shine, but it is more rigid and durable.

- For a modern appearance, you should go for a mirror finish. This type of finish has a higher reflectivity level, enhancing its appearance. This is the best finish for interior design.

- In some areas, cleability is a significant challenge. So, in this case, you should consider a finish that requires minimal cleanliness. For example, the No.6 stainless steel finish does not require regular maintenance.

- Lastly, the cost of each finishing option is different. So you should keep in account your budget. If you have a tight budget, go for No.1, No.2, and No.3 finishing. However, an etched finish is the best option if you have a high budget and are looking for customization.

Frequently Asked Questions

How to get a good finish on stainless steel?

Pre-cleaning the surface of stainless steel is crucial to attaining a good finish. Moreover, uneven surfaces do not provide a good finish. So, before starting the finishing procedure, use abrasives to make the surface even.

Is stainless steel Self-finishing?

Yes, somehow, stainless steel has self-finishing. The composition of stainless steel involves a higher content of chromium. This chromium forms an oxide layer when exposed to moisture. This layer protects the stainless steel from further corrosion.

How to restore the stainless steel finish?

Sometimes, the finish applied to stainless steel becomes dull with time. To restore this finish, you can use a small amount of polish. Apply this polish with a brush equally on the surface of stainless steel. However, this method is applicable if only the upper layer becomes dull. In case of deterioration of the finish, restoration is not possible.

Conclusion

There are several stainless steel finishing options. In this article, I have discussed ten options. All those options vary in many ways, including different production processes and costs. For example, the No.1, No.4, and No.3 finishing options provide a less reflective appearance.

Moreover, their usability also differs in many fields. However, No.6, bead-blasted, and etch finishes are some modern types of finishing. All these options provide a shiny surface. Moreover, the cost of these finishes is also high. Choosing the right one from those options is also crucial. You should understand your desire and go for the notion that suits you.